PCB and manufacturing method thereof

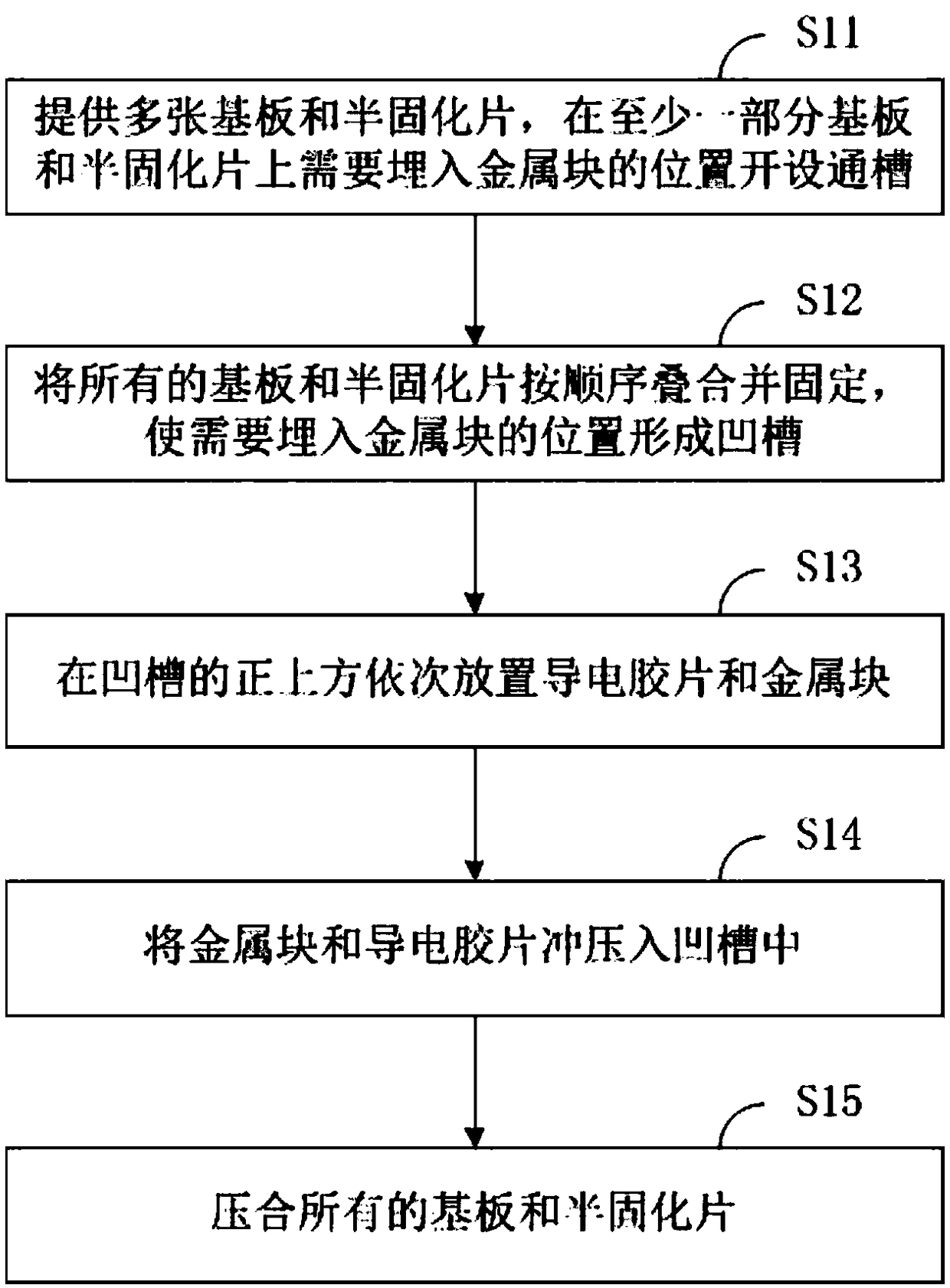

A production method and a part of the technology are applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, printed circuit components, etc., which can solve the problems of difficulty in ensuring alignment, high difficulty in picking and placing, and complicated operation, so as to avoid alignment Poor degree, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060] This embodiment provides a PCB, which is manufactured by using the manufacturing method of the PCB described in the above-mentioned embodiments.

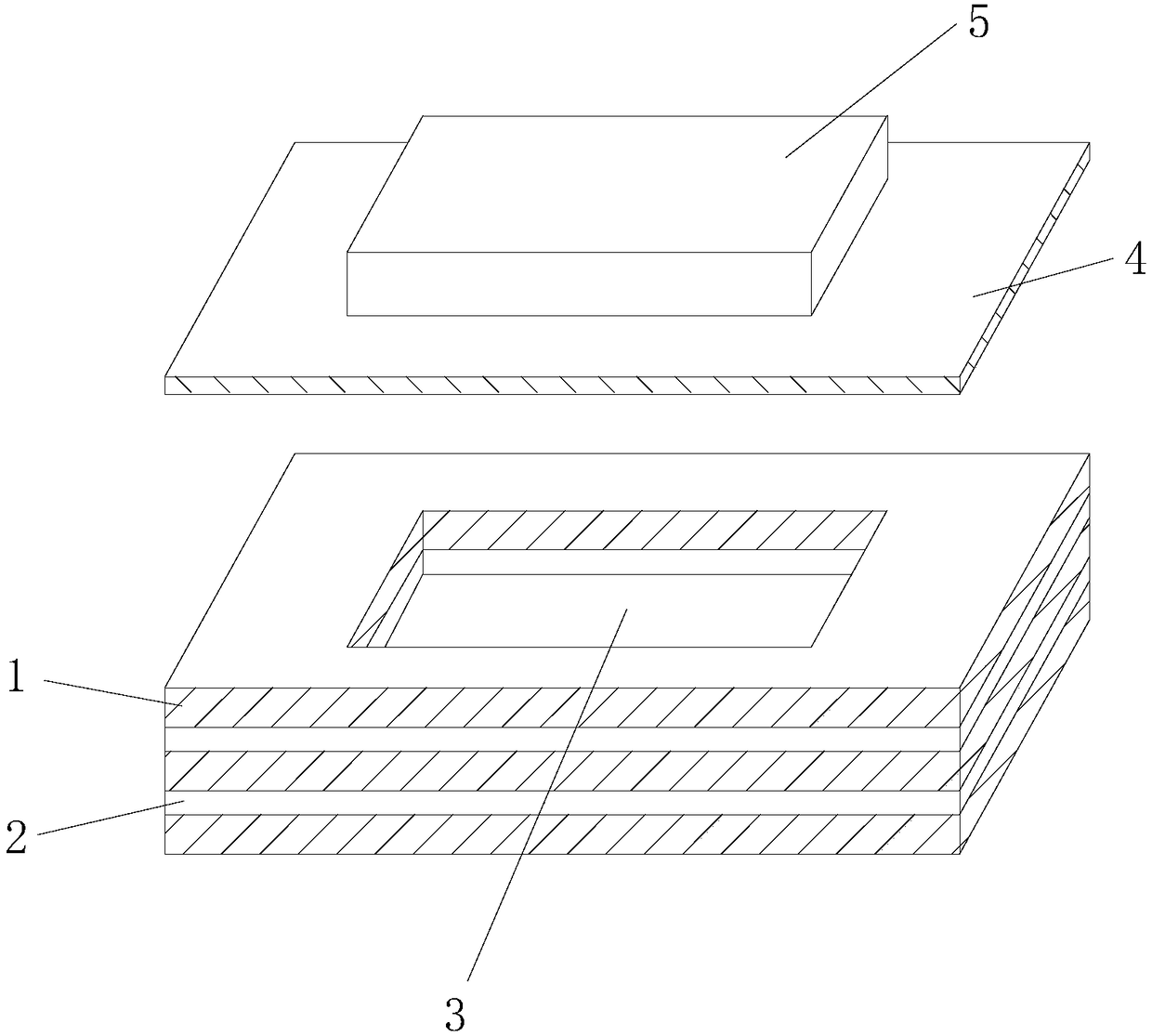

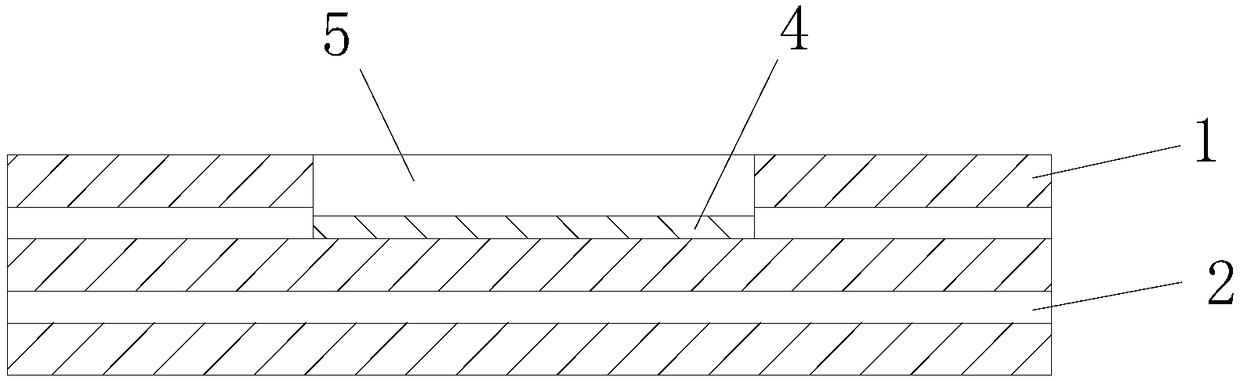

[0061] image 3It is a schematic cross-sectional view of the PCB provided in this embodiment at the position of the blind slot. Such as image 3 As shown, the groove opened on the PCB is a blind groove, and the metal block 5 and the conductive film 4 are embedded in the groove by stamping; the metal block 5 is bonded to the groove bottom of the groove through the conductive film 4 . Wherein, the size of the conductive film 4 is equal to the cross-sectional size of the groove.

[0062] Figure 4 It is a schematic cross-sectional view of the PCB provided in this embodiment at the position of the stepped blind slot. Such as Figure 4 As shown, the metal block 5 is a stepped metal block, and the groove is a stepped blind groove; the small end of the stepped metal block faces the groove bottom of the groove. The stepped plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com