A kind of purification treatment method of diesel engine exhaust

A diesel engine and exhaust gas treatment technology, which is applied in the purification treatment of nitrogen monoxide and sulfur dioxide, and in the field of particulate matter in exhaust gas, can solve the problems of unsatisfactory effect, high price, and lack of resources, so as to improve the efficiency of catalytic reaction, low cost, and avoid The effect of catalyst poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

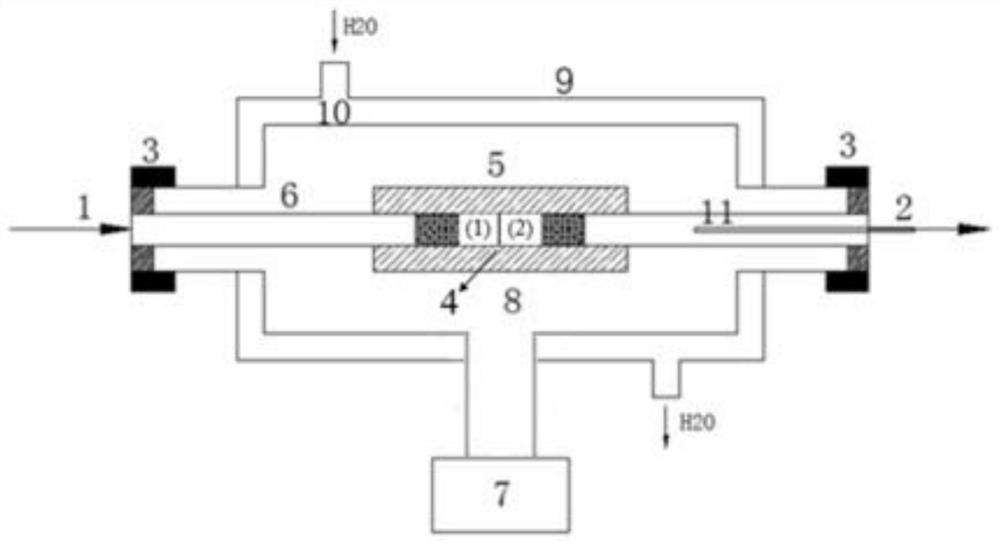

Method used

Image

Examples

Embodiment 1

[0048] Preparation of zinc oxide porous honeycomb ceramic carrier:

[0049] Powder ratio: first use a ball mill to grind the sintering aid sodium silicate for 40 minutes, and then mix it with the four-needle nano-ZnOw powder material at a mass ratio of 1:25 to obtain the powder material;

[0050] Slime preparation: Weigh 35wt% water, 1.5wt% sodium polyacrylate, 2wt% glycerin and 4wt% gum arabic, and mix with the powder raw materials to prepare plastic mass mud;

[0051] Mud blank preparation: put the plastic micellar mud material prepared in step (2) into a vacuum mud refining machine for vacuum mud refining to obtain a mud blank matching the specifications of the molding machine barrel;

[0052] Extrusion molding: put the mud base obtained in step (3) into a vacuum extruder, and extrude a zinc oxide honeycomb ceramic green base with an inner diameter of 45 mm and an aperture of 1 mm through a die;

[0053] Drying and shaping: place the honeycomb ceramics prepared in step (4...

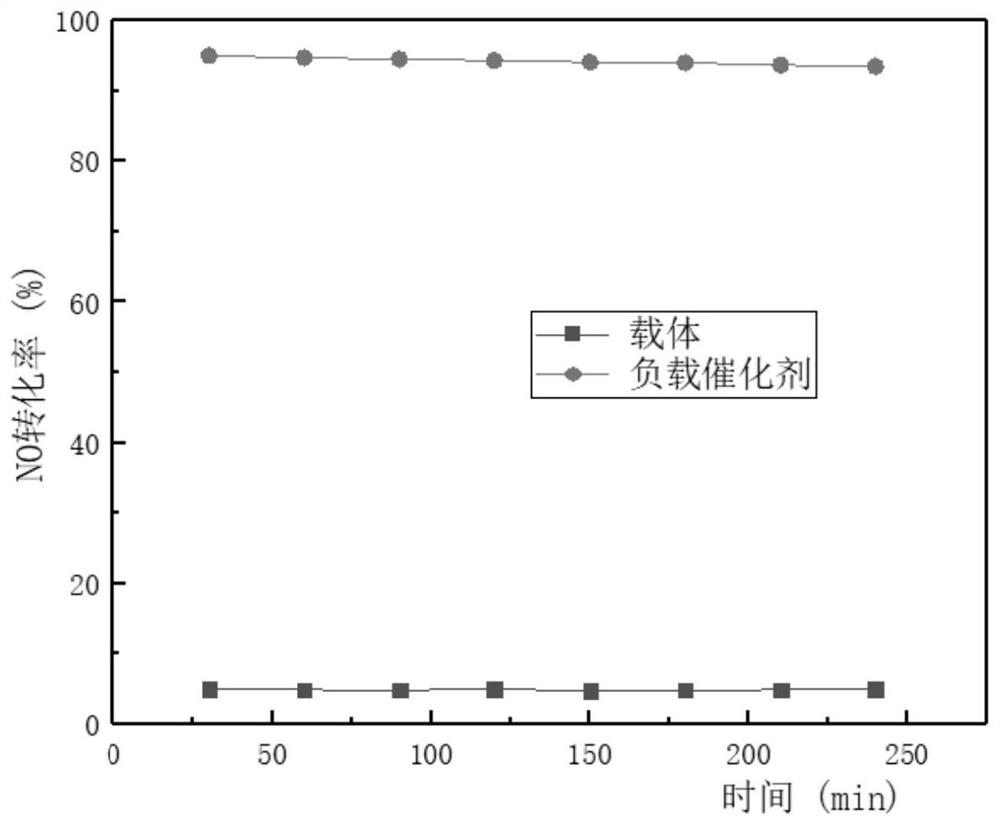

Embodiment 2

[0061] (1) Catalyst sol preparation: according to the molar ratio La:Ce:Ni=8:2:10, weigh 0.016mol lanthanum nitrate, 0.004mol cerium nitrate and 0.02mol nickel nitrate and dissolve them in 100ml water, then add 0.052mol citric acid Prepare a mixed solution, heat it in a water bath to 75°C and keep it warm for 3.5 hours to obtain a sol; (2) Carrier impregnation and drying: take 100ml of sol and impregnate 100g of zinc oxide honeycomb ceramic carrier for 15 minutes, then take out the impregnated carrier and put it in a microwave oven. Raise the temperature to 90°C and dry for 3 hours. After the drying is completed, repeat the above steps, impregnate and dry the carrier twice to obtain the pre-coated carrier; (3) Calcination: place the above-mentioned coated carrier in a microwave sintering furnace In the process, the temperature was raised to 600°C under the action of microwaves and calcined for 2 hours, and finally zinc oxide honeycomb ceramics loaded with lanthanum-cerium-nicke...

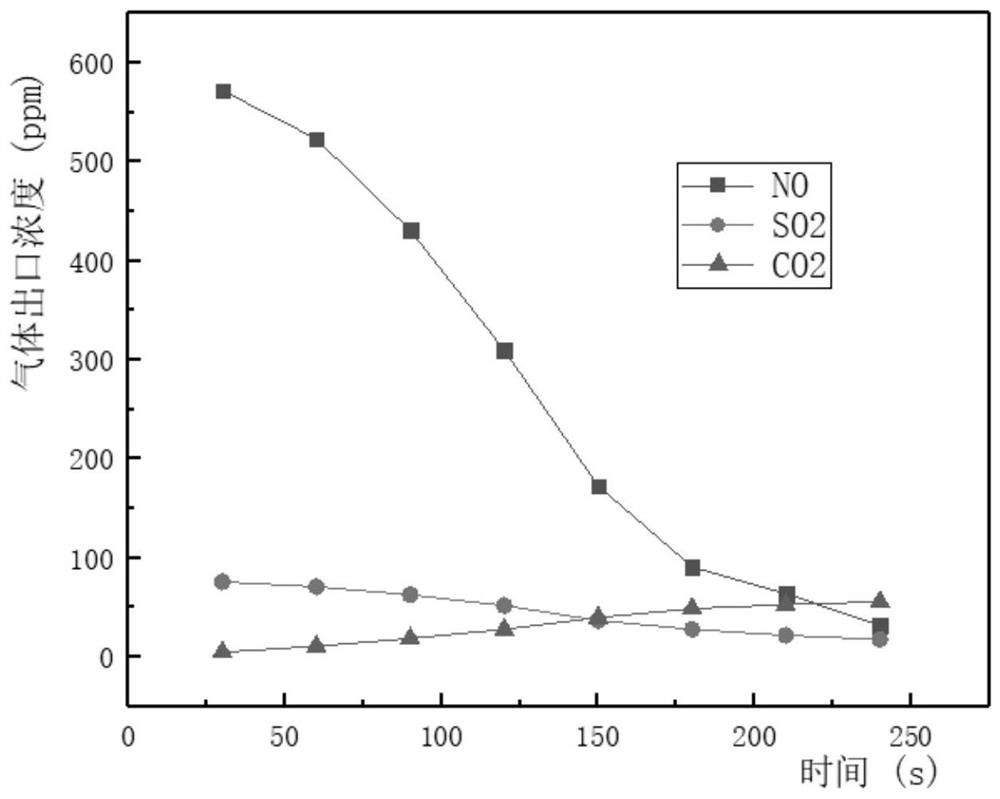

Embodiment 3

[0063] (1) Catalyst sol preparation: Weigh 0.014mol lanthanum nitrate, 0.006mol cerium nitrate and 0.02mol nickel nitrate respectively according to the molar ratio La:Ce:Ni=7:3:10 and dissolve them in 100ml water, then add 0.056mol citric acid Prepare a mixed solution, heat it in a water bath to 80°C and keep it warm for 3 hours to obtain a sol; (2) Carrier impregnation and drying: take 100ml of sol and impregnate 100g of zinc oxide honeycomb ceramic carrier for 18 minutes, then take out the impregnated carrier and put it in a microwave oven. Raise the temperature to 100°C and dry for 2.5 hours. After the drying is completed, repeat the above steps, impregnate and dry the carrier twice to obtain the pre-coated carrier; (3) Calcination: place the above-mentioned coated carrier in a microwave sintering furnace In the process, the temperature was raised to 700°C under the action of microwaves and calcined for 2 hours, and finally zinc oxide honeycomb ceramics loaded with lanthanum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com