Integrated atomizing sterilizer

A sterilizer and housing technology, applied in disinfection, chemistry, construction, etc., can solve problems such as difficult control of sterilizing concentration, excessive dilution of hydrogen peroxide, complex internal structure, etc., to avoid the reduction of fog concentration, optimize the internal structure, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

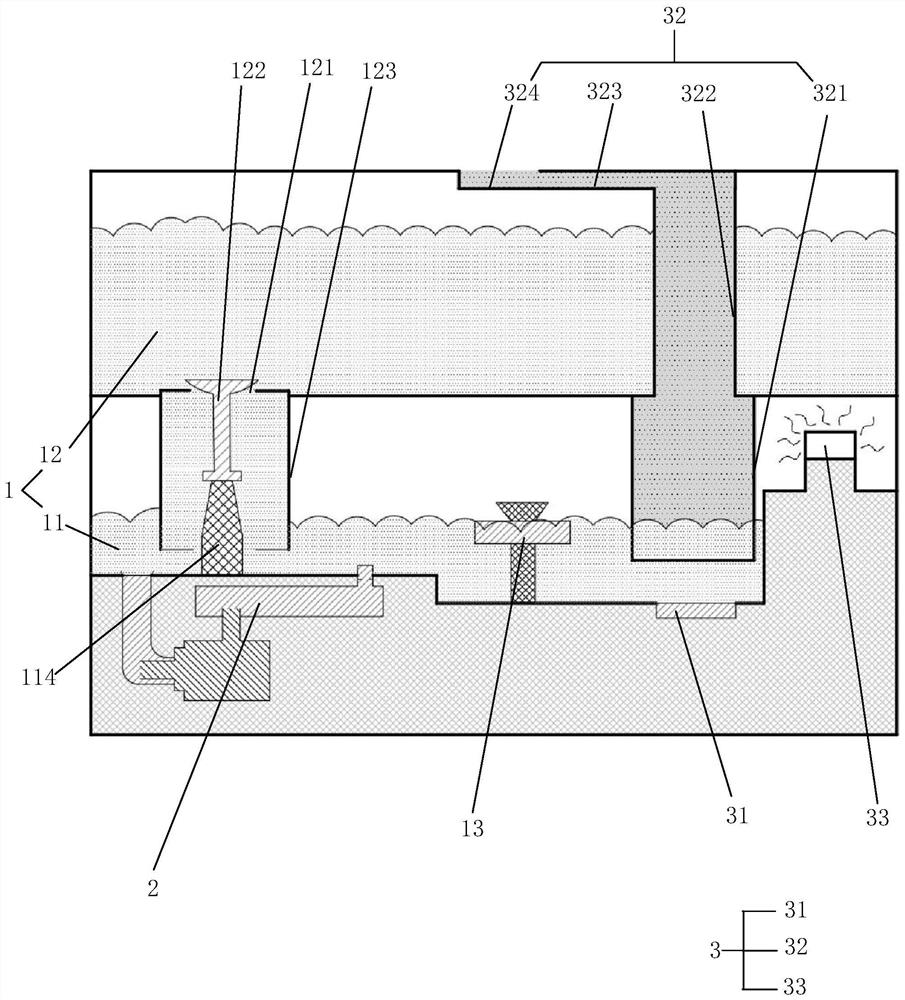

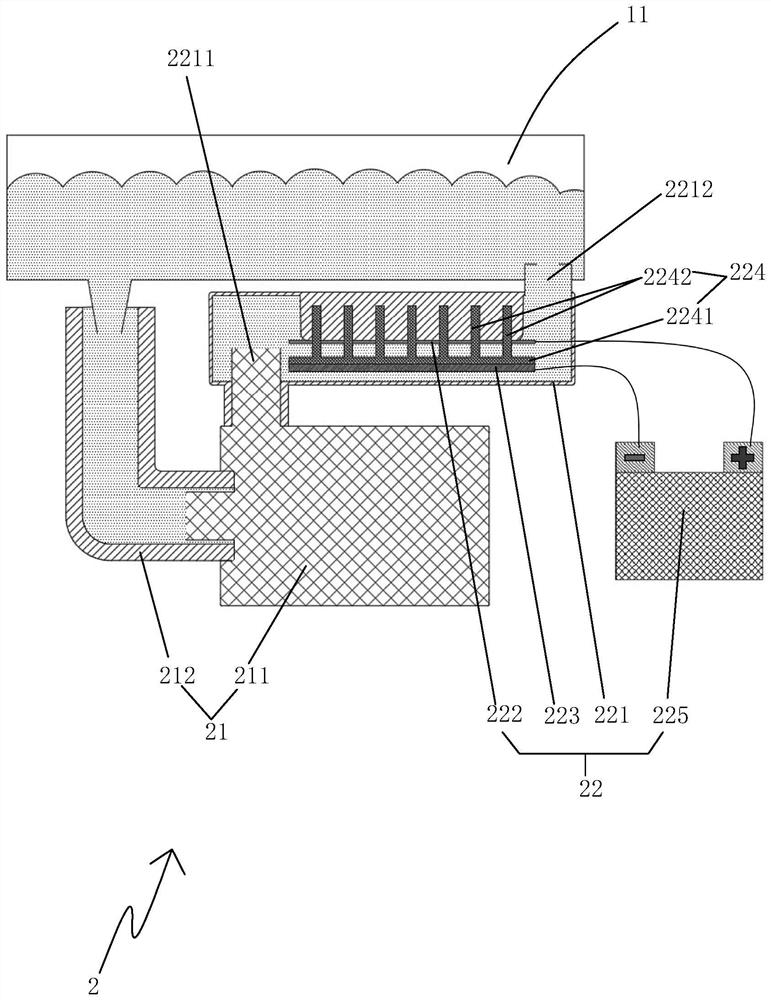

[0029] like Figure 1-3 As shown, the integrated atomization and disinfection machine includes a liquid storage mechanism 1, a reaction mechanism 2 and an atomization mechanism 3; the liquid storage mechanism 1 includes a liquid storage tank 11 and a liquid supply tank 12, and the liquid storage tank 11 is used to hold Electrolyte, the liquid supply tank 12 is provided on the upper side of the liquid storage tank 11 to provide it with electrolyte; the reaction mechanism 2 includes a liquid supply module 21 and a reaction module 22, and the liquid supply module 21 is used to The electrolyte in the storage tank 11 is transported to the reaction module 22, and the reaction module 22 is used to electrolyze the electrolyte to make hydrogen peroxide disinfectant and flow into the storage tank 11; atomization mechanism 3. It includes an atomization module 31, an air duct structure 32 and a fan module 33. The atomization module 31 is arranged in the liquid storage tank 11 for atomizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com