A cathode and anode built-in electrochemical microfiltration membrane bioreactor and its application

A bioreactor and microfiltration membrane technology, applied in the field of water treatment, can solve the problems of difficult removal of trace or trace organic matter, secondary point source pollution, etc., and achieve the effects of slowing down membrane fouling, reducing membrane fouling, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

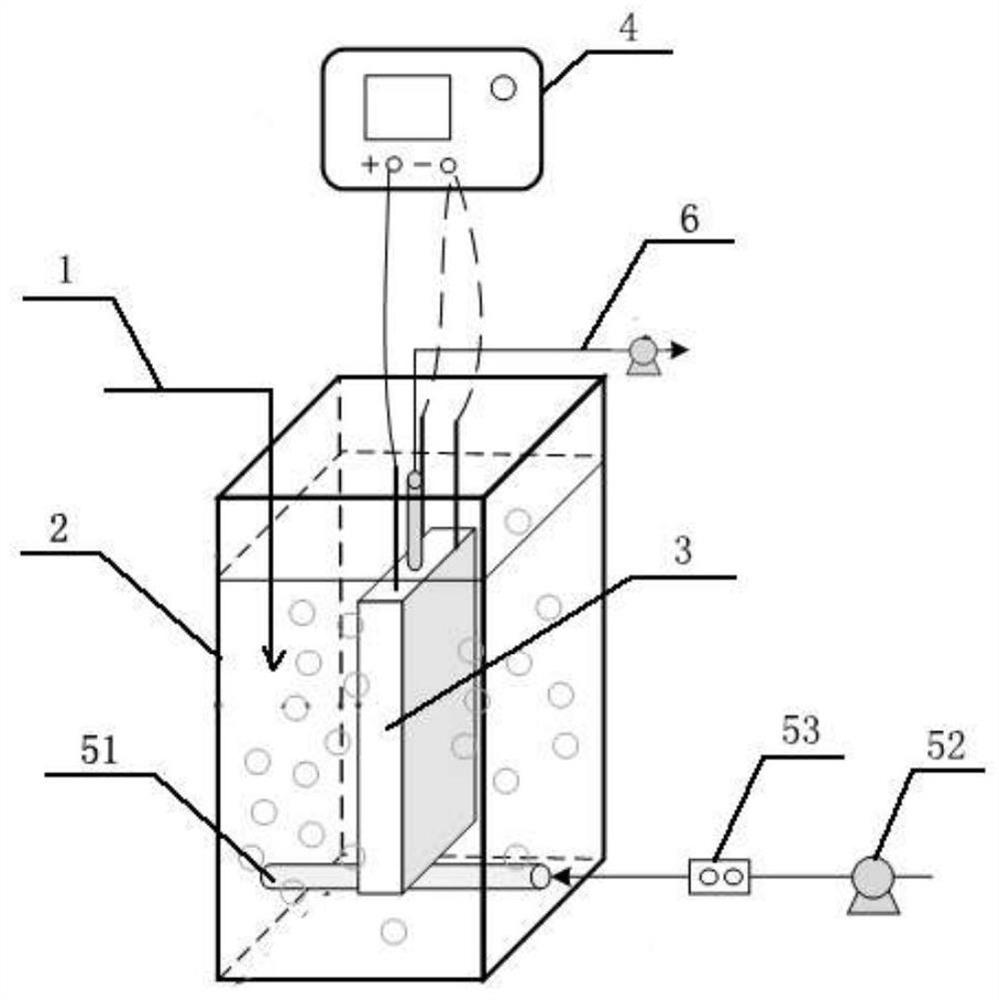

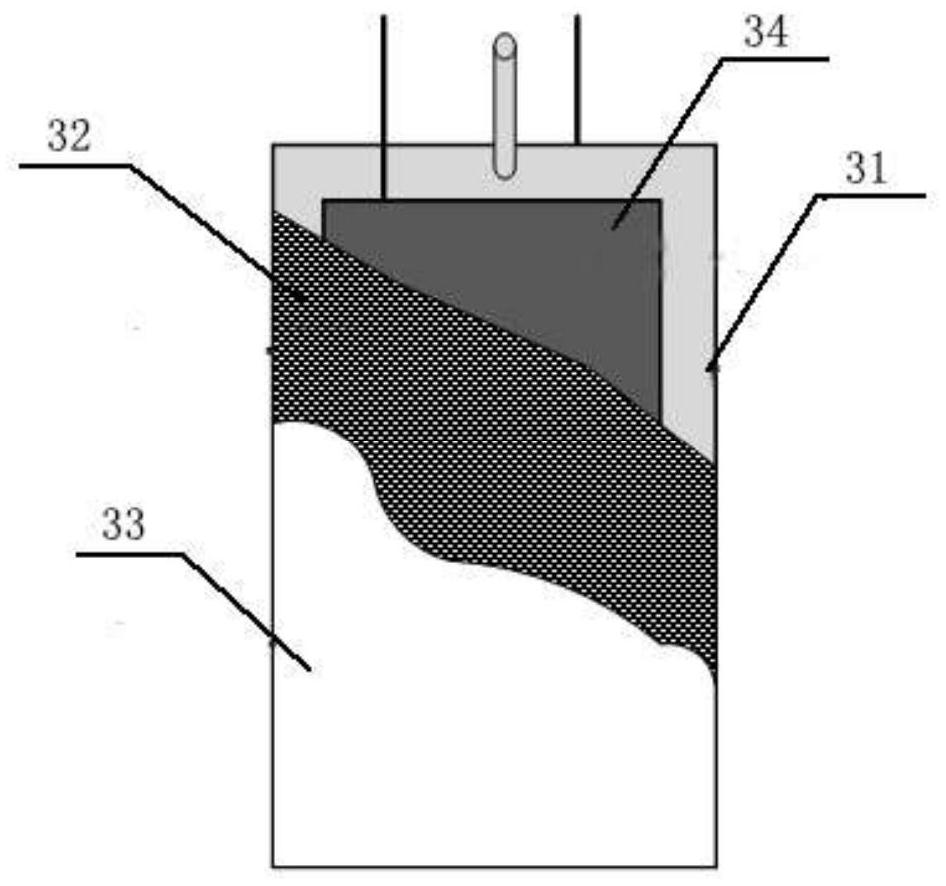

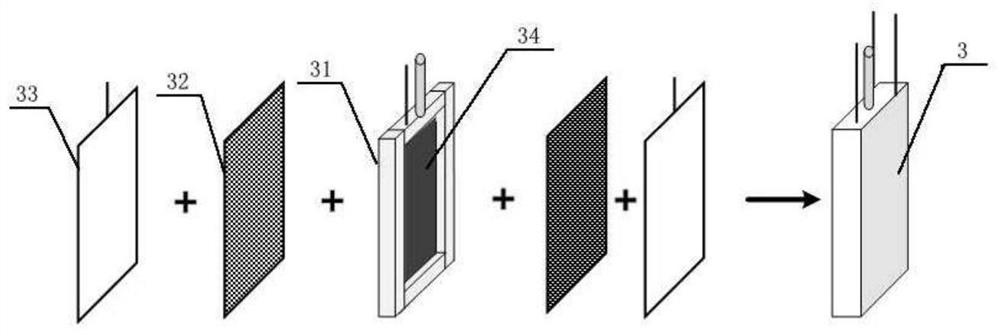

[0027] A cathode and anode built-in electrochemical microfiltration membrane bioreactor, comprising a water inlet pipe 1, a reactor housing 2, an electrochemical microfiltration membrane assembly 3, a stabilized DC power supply 4, an aeration system and an outlet pipe 6; One end of the water inlet pipe 1 is placed in the reactor housing 2; the electrochemical microfiltration membrane module 3 is arranged in the reactor housing 2, and the electrochemical microfiltration membrane module 3 includes a membrane frame 31, a guide net 32, an embedded Steel mesh flat microfiltration membrane 33 and titanium-based IrO 2 / Ta 2 O coating anode 34, described film frame 31 is provided with the suction port that communicates with film frame 31 lumens, and suction port is connected with outlet pipe 6, is provided with titanium-based IrO in the film frame 31 cavity. 2 / Ta 2 O-coated anode 34, titanium-based IrO 2 / Ta 2 The O-coated anode 34 is connected to the positive pole of the stabili...

Embodiment 2

[0031] A cathode and anode built-in electrochemical microfiltration membrane bioreactor, comprising a water inlet pipe 1, a reactor housing 2, an electrochemical microfiltration membrane assembly 3, a stabilized DC power supply 4, an aeration system and an outlet pipe 6; One end of the water inlet pipe 1 is placed in the reactor housing 2; the electrochemical microfiltration membrane module 3 is arranged in the reactor housing 2, and the electrochemical microfiltration membrane module 3 includes a membrane frame 31, a guide net 32 and an embedded A flat microfiltration membrane 33 of steel mesh, the membrane frame 31 is provided with a suction port communicating with the cavity of the membrane frame 31, the suction port is connected to the outlet pipe 6, and the cavity of the membrane frame 31 is provided with a titanium-based IrO 2 / Ta 2 O-coated anode 34, titanium-based IrO 2 / Ta 2 The O-coated anode 34 is connected to the positive pole of the stabilized DC power supply ...

Embodiment 3

[0035] A cathode and anode built-in electrochemical microfiltration membrane bioreactor, comprising a water inlet pipe 1, a reactor housing 2, an electrochemical microfiltration membrane assembly 3, a stabilized DC power supply 4, an aeration system and an outlet pipe 6; One end of the water inlet pipe 1 is placed in the reactor housing 2; the electrochemical microfiltration membrane module 3 is arranged in the reactor housing 2, and the electrochemical microfiltration membrane module 3 includes a membrane frame 31, a guide net 32 and an embedded A flat microfiltration membrane 33 of steel mesh, the membrane frame 31 is provided with a suction port communicating with the cavity of the membrane frame 31, the suction port is connected to the outlet pipe 6, and the cavity of the membrane frame 31 is provided with a titanium-based IrO 2 / Ta 2 O-coated anode 34, titanium-based IrO 2 / Ta 2 The O-coated anode 34 is connected to the positive pole of the regulated direct current po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com