A kind of wood carbonization processing method and equipment

A carbonization treatment, wood technology, applied in wood processing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve the problems of unable to carbonize wood, poor carbonization effect, deformation and cracking, etc., to achieve moisture content Uniform, not prone to cracks, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

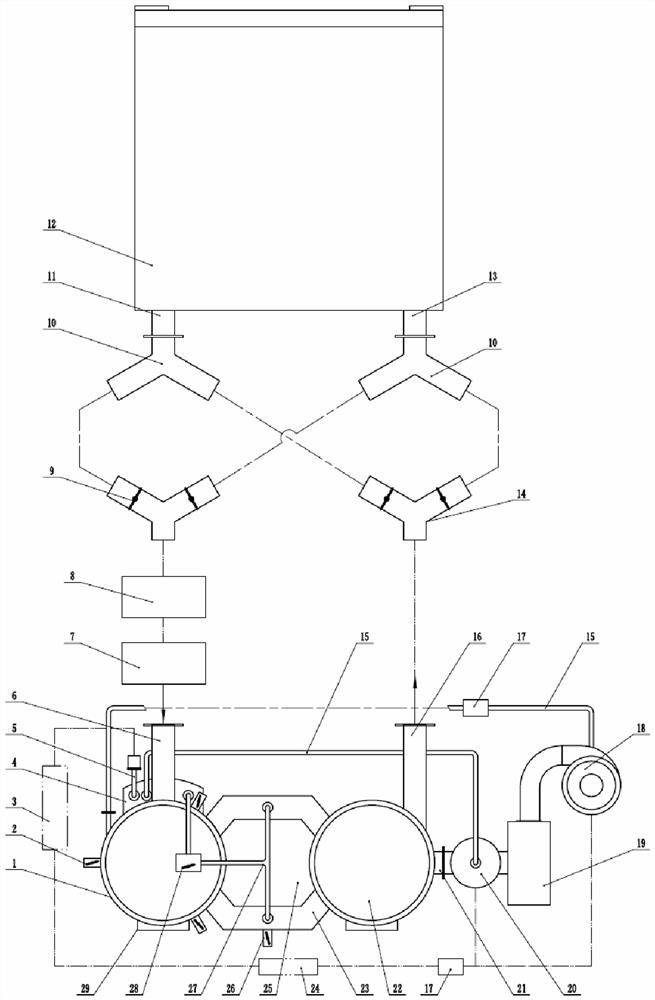

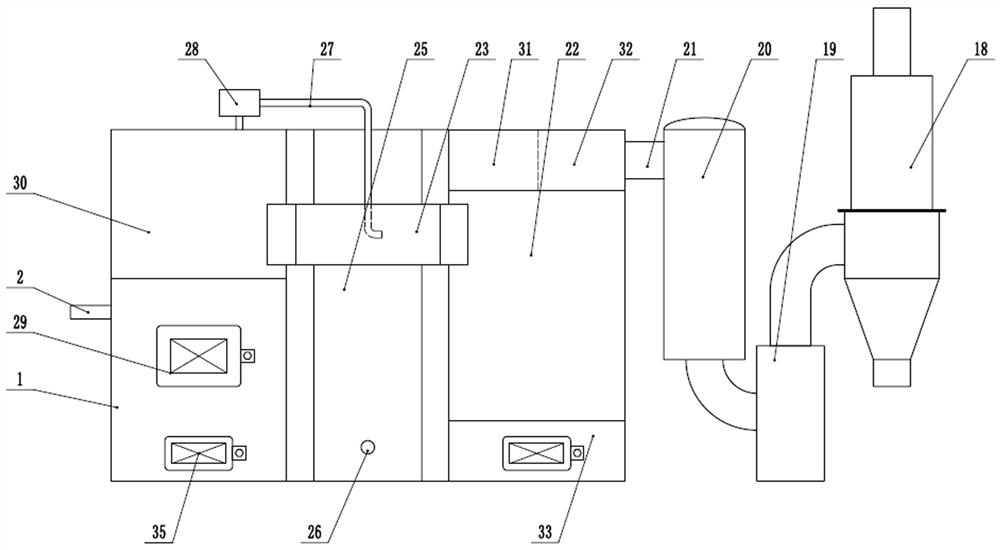

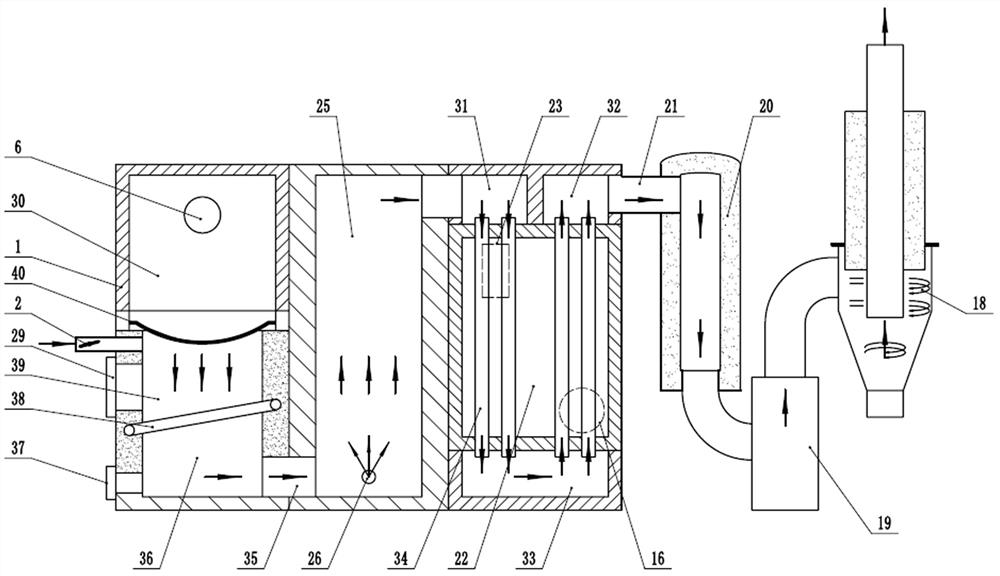

Method used

Image

Examples

Embodiment 1

[0042] Wood carbonization can be accomplished in the following steps:

[0043] (1) Palletize the wood in the carbonization box for balanced moisture content treatment. The temperature in the carbonization box is 60-120°C and the humidity is 100%RH. The working time is 96 hours, 0-24 hours at 60°C, and 24-48 hours at 80°C , 48-72 hours at 100°C, 72-96 hours at 120°C.

[0044] (2) Dry the wood after the equilibrium moisture content treatment to ensure that the temperature in the carbonization box is 100-120°C, the humidity is 100-20%RH, the humidity gradient is decreasing, and the operation time is about 72 hours.

[0045] (3) Carry out carbonization treatment on the dried wood. After the drying stage is over, raise the temperature in the carbonization box from 120°C to 190-220°C, increasing by 10°C every 2 hours; when entering the carbonization temperature, strictly control the carbonization The time is calculated according to the thickness of the plate, and the carbonization sp...

Embodiment 2

[0048] Wood carbonization can be accomplished in the following steps:

[0049] (1) Palletize the wood in the carbonization box of the carbonization treatment device for balanced moisture content treatment, and use the counter-burning combustion device of the carbonization treatment device to provide hot air and steam to ensure that the temperature in the carbonization box is 60-120 °C and the humidity is 100%. RH, working time 96 hours, 0-24 hours at 60°C, 24-48 hours at 80°C, 48-72 hours at 100°C, 72-96 hours at 120°C.

[0050] (2) Dry the wood after the equilibrium moisture content treatment, and use the counter-burning combustion device of the carbonization treatment device to provide hot air and steam to ensure that the temperature in the carbonization box is 100-120°C, the humidity is 100-20%RH, and the humidity gradient Decrease, the working time is about 72 hours.

[0051] (3) Carry out carbonization treatment on the dried wood. After the drying stage is over, raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com