Purification equipment for preparing carbonic ester

A carbonate and equipment technology, which is applied in the field of purification equipment for carbonate preparation, can solve problems such as carbon dioxide emissions, and achieve the effect of controlling the purification rate and reasonable purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

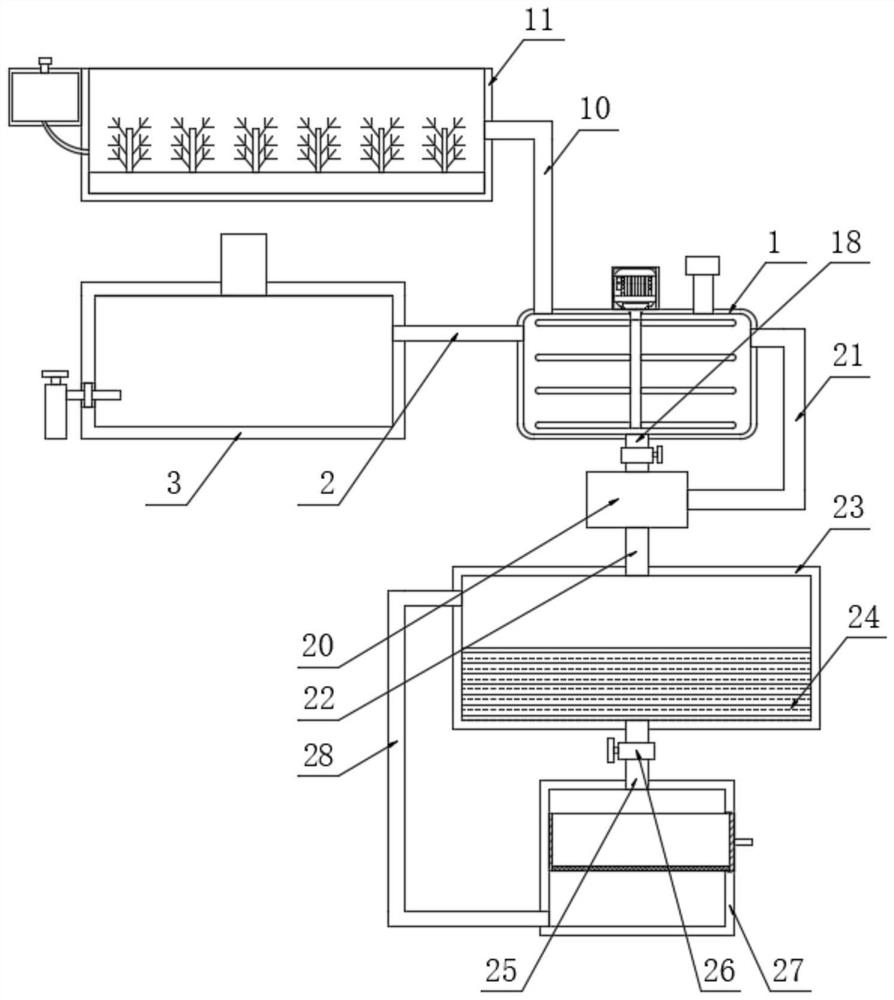

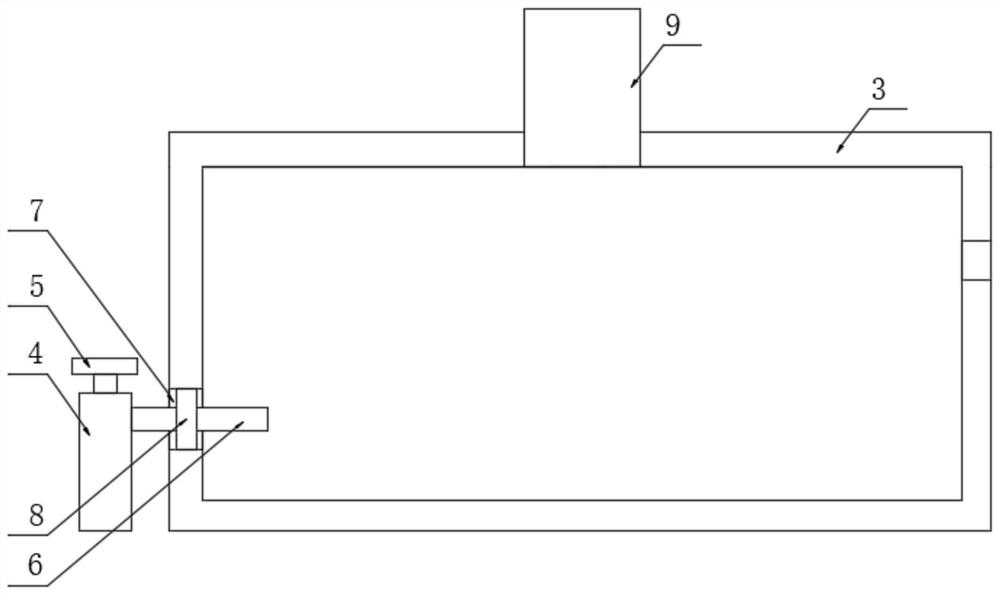

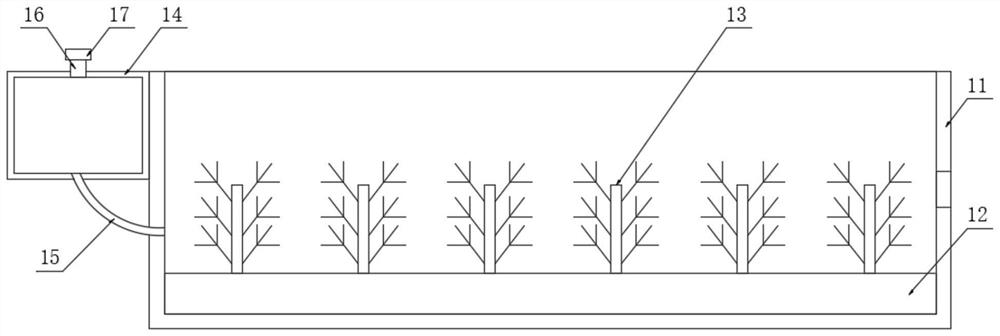

[0033] like Figure 1-6As shown, the embodiment of the present invention provides a purification device for carbonate preparation, including a mixing tank 1, a feeding pipe 101 is fixedly connected to one side of the upper surface of the mixing tank 1, and a feeding pipe 101 is fixedly connected to the upper surface of the feeding pipe 101. The second sealing cover 102, a motor 103 is fixedly connected to the center of the upper surface of the mixing tank 1, a stirring shaft 104 is fixedly connected to the output end of the motor 103, and a plurality of mixing stirring rods 105 are fixedly connected to the surface of the stirring shaft 104. The mixing tank 1 A first exhaust gas output pipe 2 is fixedly connected to the upper surface of one side, and one end of the first exhaust gas output pipe 2 is fixedly connected to a combustion box 3. One side of the combustion box 3 is provided with a burner 4, and the upper surface of the burner 4 is provided with a Press the switch 5, a...

Embodiment 2

[0036] like figure 1 As shown, a discharge pipe 18 is fixedly connected to the center of the lower surface of the mixing tank 1, a first control valve 19 is fixedly connected to the surface of the discharge pipe 18, and a discharge return box 20 is fixedly connected to the lower end of the discharge pipe 18. One end of the material return tank 20 is fixedly connected with a first return pipe 21, the other end of the first return pipe 21 is fixedly connected with the upper surface of one side of the mixing tank 1, and the center of the lower surface of the discharge return tank 20 is fixedly connected with a connecting pipe. 22, the lower end of the connecting pipe 22 is fixedly connected with a de-based box 23, the inner wall of the de-based box 23 is provided with an aqueous sodium hydroxide solution 24, and the center of the lower surface of the de-based box 23 is fixedly connected with a feeding pipe 25, the feeding pipe 25 A second control valve 26 is fixedly connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap