Numerical control bending machine feeding device with guiding function

A technology of feeding device and bending machine, which is applied in the direction of storage device, feeding device, positioning device, etc., can solve the problems of reduced production precision, low degree of automation, and difficulty in ensuring the feeding work of CNC bending machine, so as to avoid offset The effect of processing position, improving stability, improving bending efficiency and production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

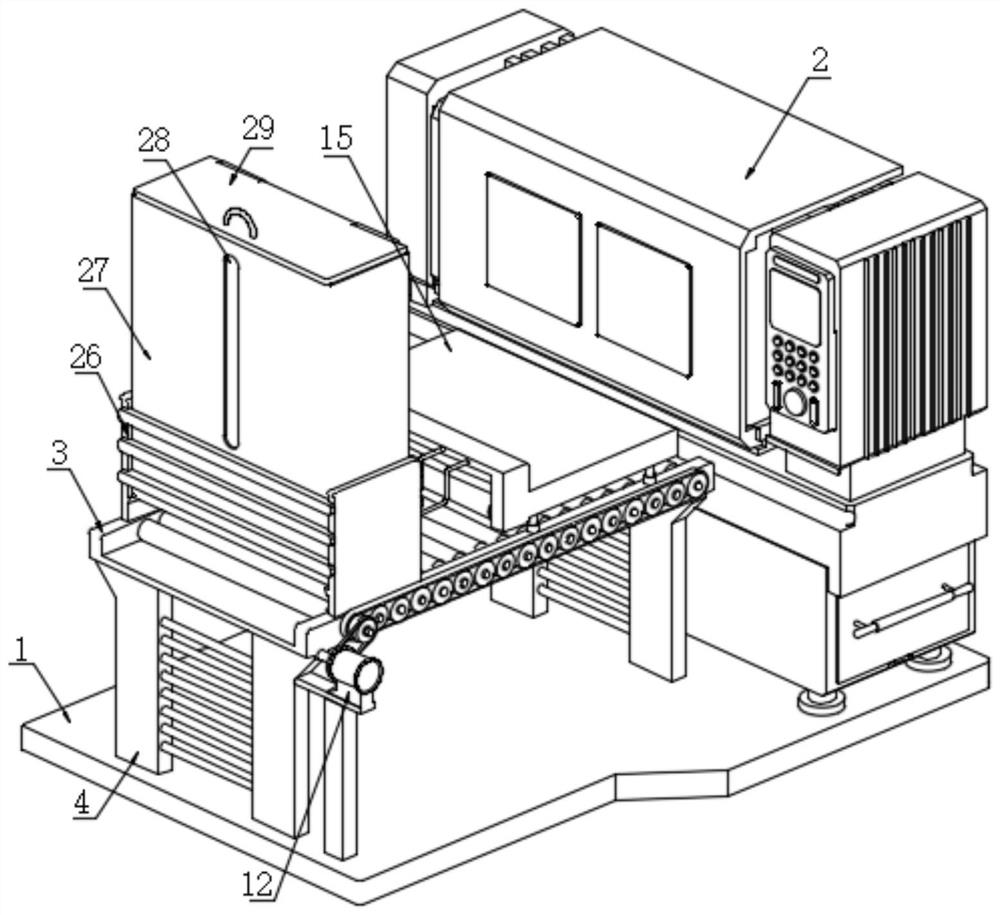

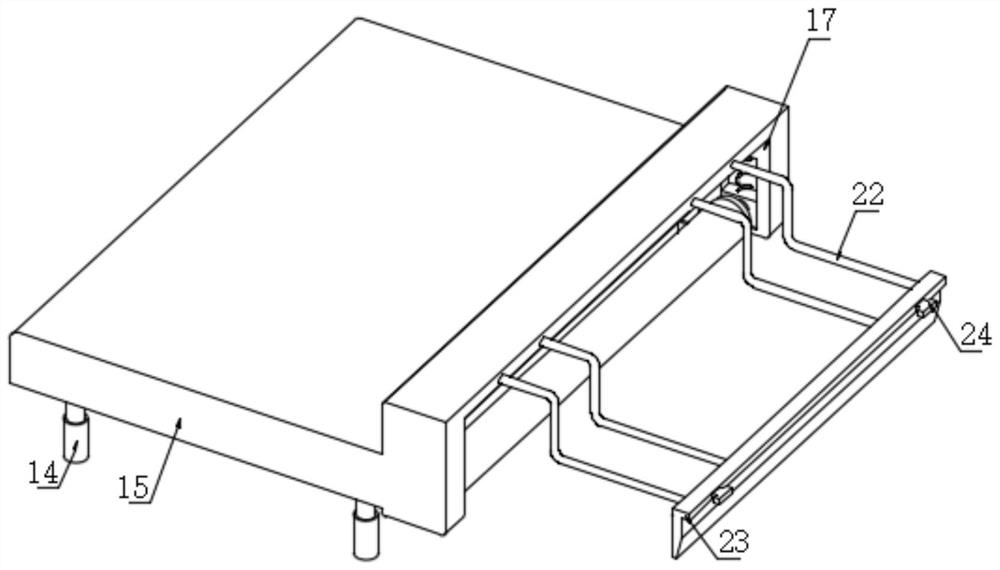

[0030] like Figure 1-6 As shown, the present invention provides a technical solution: a feeding device for a CNC bending machine with a guiding function, comprising a base plate 1, the upper surface of the base plate 1 is fixedly connected with the lower surface of the bending machine body 2, and the bending machine body 2 A base 3 is arranged in front of the base 3, and the front and rear sides of the lower surface of the base 3 are fixedly connected with the upper surface of the bottom plate 1 through the support legs 4. The upper surface of the base 3 is provided with a groove 5, and the groove 5 is provided with a number of first The guide rollers 6 and the right ends of several first guide rollers 6 are all fixedly connected with transmission wheels 7, and several transmission wheels 7 are connected by transmission through the same tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com