Thread passing device in embroidery machine

An embroidery machine and thread-passing technology, which is applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve the problems of upper thread tension adjustment error, decline in embroidery quality, and change in elastic coefficient, and achieve accurate waxing and reduce The effect of fuzzing and wax reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

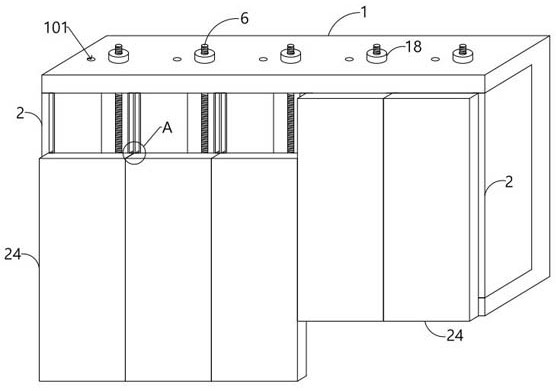

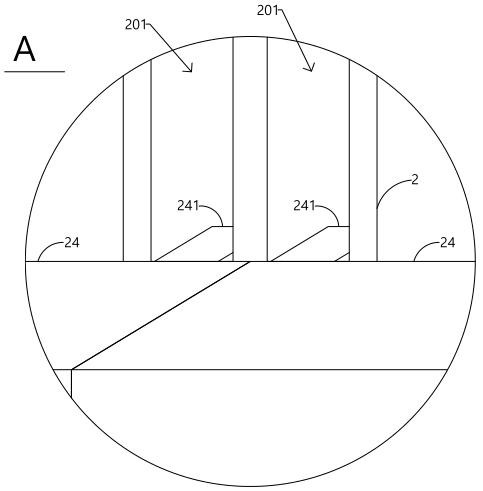

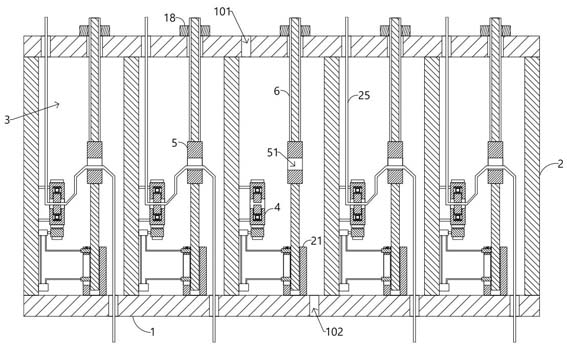

[0035] A thread-passing device in an embroidery machine, comprising a thread-passing box 1, a plurality of partitions 2 are vertically and equally spaced in the thread-passing box 1, and the partitions 2 divide the inner space of the thread-passing box 1 into a plurality of middle thread-passing cavities. 3. The setting of the partition plate 2 divides the wire passing box 1 into a plurality of middle wire passing chambers 3, so that the embroidery threads 25 are transported in the corresponding middle thread passing chambers 3, so as to prevent the embroidery threads 25 from interfering with each other and causing winding 2. To solve the problem of spooling and winding, the upper plate body of the wire-passing box 1 is provided with a wire inlet hole 101 that communicates with the middle wire-passing cavity 3, and the lower plate body of the wire-passing box 1 is provided with a wire outlet hole that communicates with the middle wire-passing cavity 3. 102. A rotating gear 4 wi...

Embodiment 2

[0041] The second embodiment increases the fixing effect of the tension adjusting rod 6 on the basis of the first embodiment, that is: the outer side of the tension adjusting rod 6 is provided with a threaded structure, and the end of the tension adjusting rod 6 extending out of the wire box 1 is threadedly connected with a lock. For the nut 18, when the tension adjustment rod 6 pulls the tension adjustment block 5 to move to a predetermined position, the locking nut 18 is sleeved on the tension adjustment rod 6, and the tension adjustment rod 6 is locked and fixed, which is simple and convenient.

Embodiment 3

[0043] The third embodiment discloses the rotation setting of the rotating gear 4 on the basis of the first embodiment, that is, the rotating gear 4 is provided with a sliding ring groove 43 for slidingly placing the limit block 20, and the limit block 20 is fixedly connected with a sliding extension. The support rod 19 of the rotating gear 4 is pulled out. The support rod 19 is fixedly connected to the inner wall of the middle wire cavity 3, and the rotating gear 4 is supported by the cooperation of the support rod 19 and the limit block 20, so that the rotating gear 4 can rotate stably. The limit blocks 20 are preferably two and symmetrically arranged, and the two limit blocks 20 are fixedly connected with the support rods 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com