Bealock hole cast-in-place wall structure and construction method

A technology of cast-in-place walls and pass walls, which is applied to building structures, formwork/formwork/work frames, and on-site preparation of building components. It can solve the problems affecting the construction work and the construction process of aerated concrete block walls Many, irregular cracks and other problems, to achieve the effect of eliminating dust pollution on the construction site, reducing labor and material costs, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

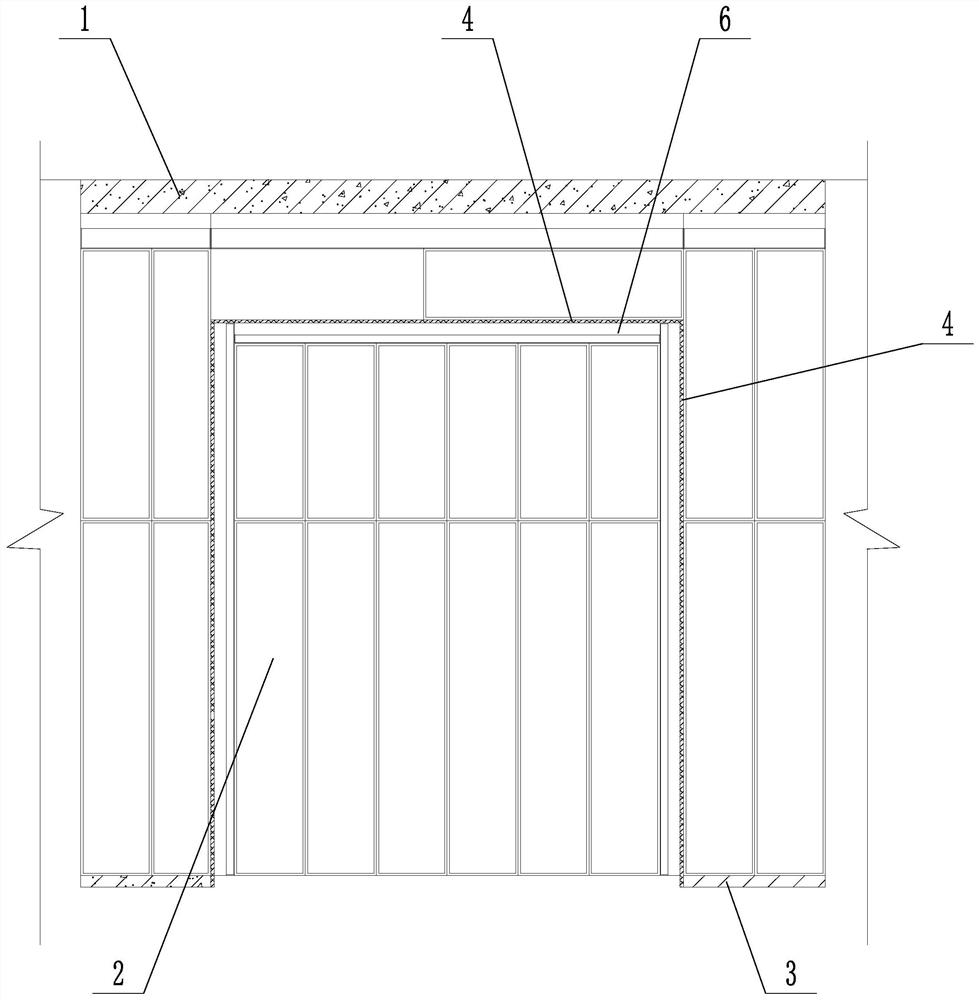

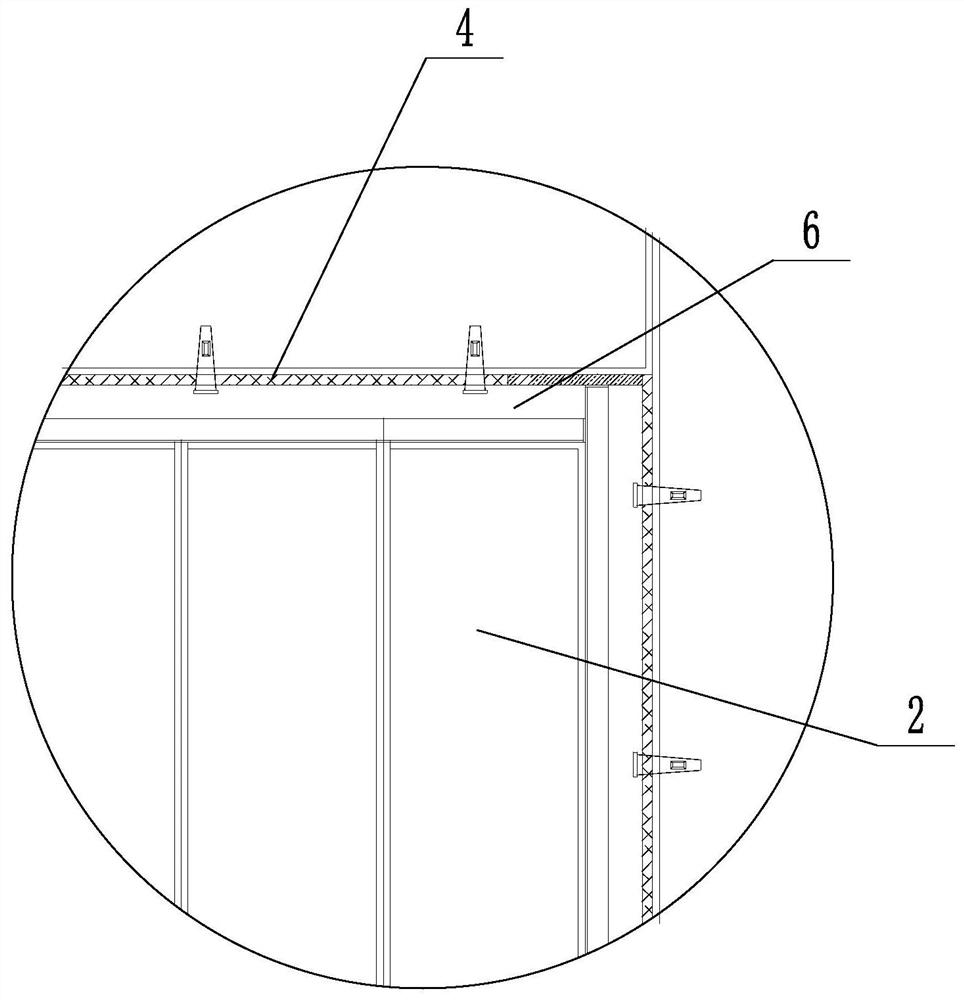

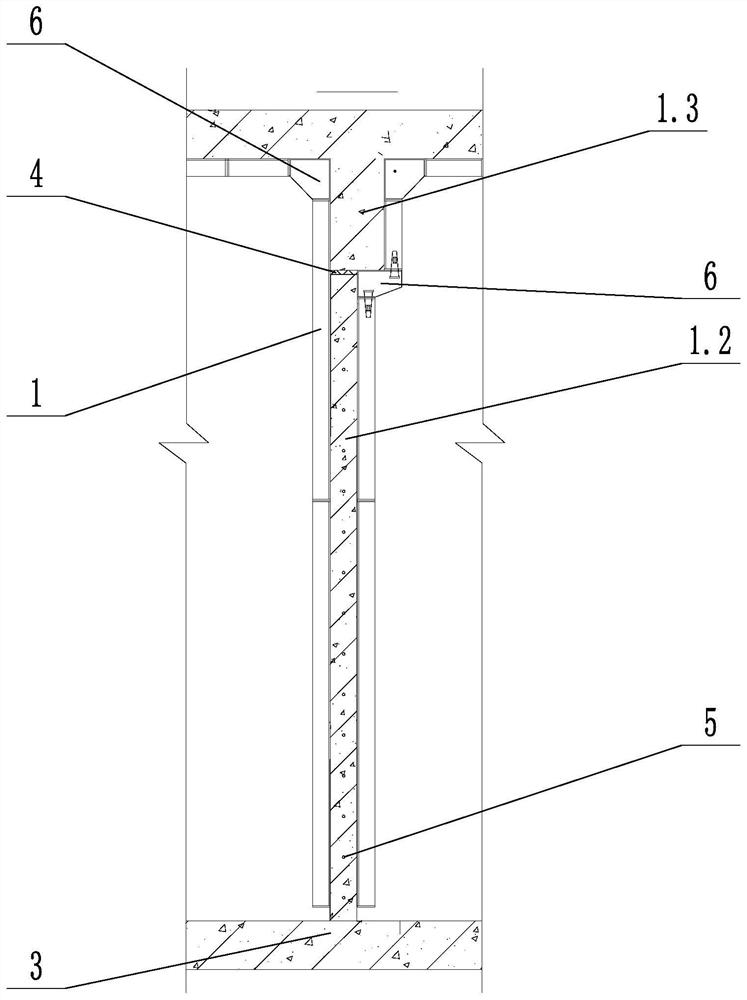

[0033] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of cast-in-situ wall structure of a pass hole comprises a cast-in-place wall 1, a formwork 2 and a base plate 3, the cast-in-place wall 1 and the formwork 2 are arranged above the base plate 3, and the cast-in-place wall 1 is arranged in the formwork 2; The cast-in-place wall 1 includes a pass wall 1.1, a shear wall 1.2 and a frame beam 1.3. A wood wool board 4 is provided between the pass wall 1.1 and the shear wall 1.2, and a wood wool board is provided between the pass wall 1.1 and the frame beam 1.3. 4. The wood wool board 4 is fixed with the formwork 2, and a pouring hole 4.1 is provided on the wood wool board 4 between the pass wall 1.1 and the frame beam 1.3. The pass wall 1.1 is provided with a single-layer two-way reinforcing mesh sheet 5, and the ends of the two-way reinforcing mesh sheet 5 pass through the wood wool board 4 and are bound and connected with the main reinforcement in the sh...

Embodiment 2

[0036] A construction method for a cast-in-place wall of a Yakou cave, which adopts the above-mentioned cast-in-situ wall structure of a Yakou cave, comprising the following steps:

[0037] a. Reinforcing bar bundling: Bind the reinforcing bars at the position where the cast-in-place wall 1 needs to be poured, and at the same time place the wood wool board 4 at the set position; when the reinforcing bars are bundled, the single-layer two-way reinforcing mesh sheet 5 is used in the entrance wall 1.1. The ends of the steel mesh in 1.1 pass through the wood wool board 4 that is in contact with the wall, and the steel bars are inserted into the shear wall 1.2 at both ends and the top frame beam 1.3 to bind and connect with the main reinforcement of the structure;

[0038] b. Formwork fixing: fix the formwork 2 on the outside of the cast-in-place wall 1 to be poured, and fix the wood wool board 4 on the formwork 2;

[0039] c. Layered pouring: pour the pass wall 1.1 and the shear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com