A kind of preparation method of high-performance graphite sealing material

A graphite-sealed, high-performance technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of insufficient compact structure, waste of raw materials, large porosity, etc., and achieve the effect of increasing the rate of roasting yield, reducing production costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

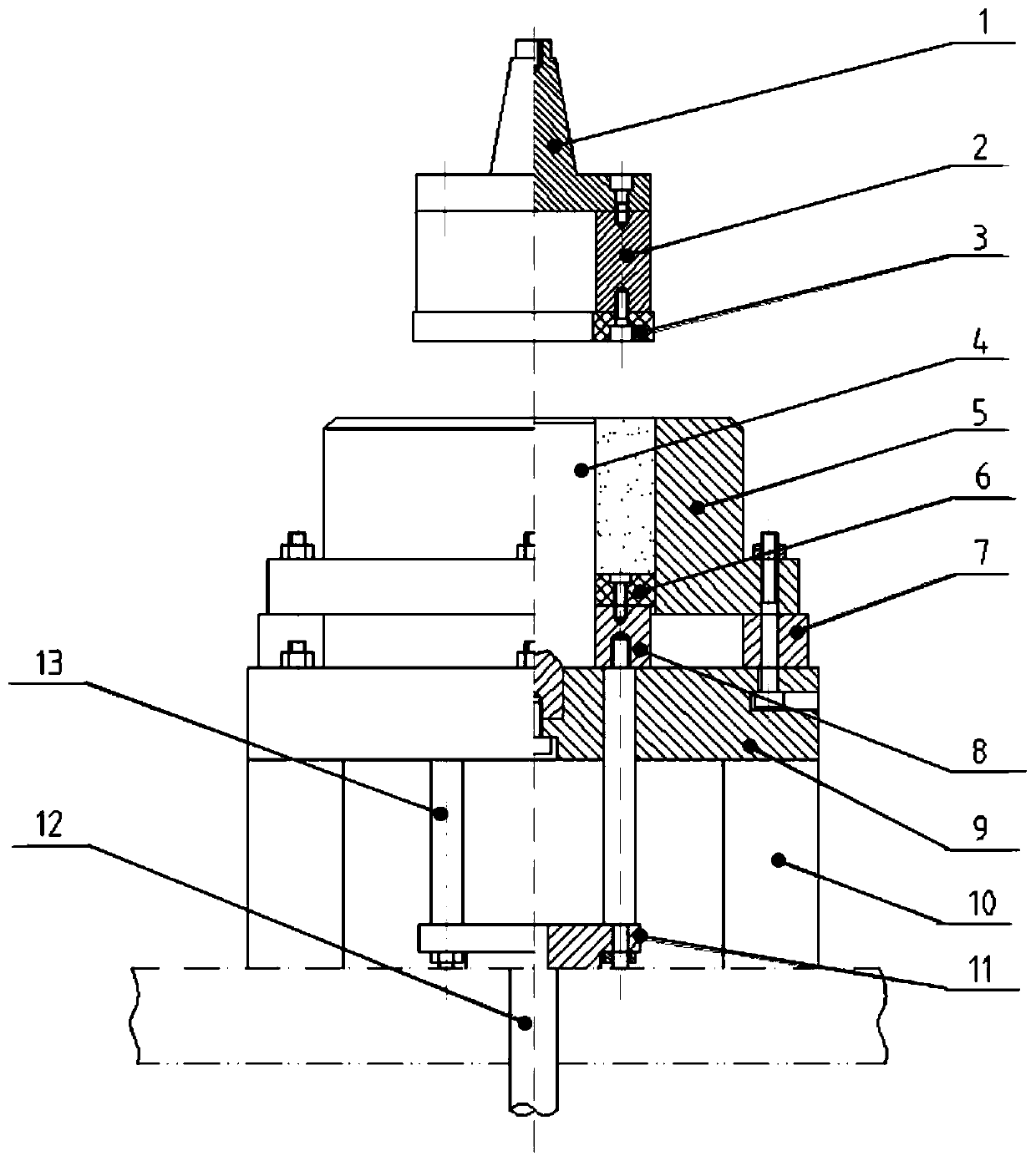

Image

Examples

Embodiment 1

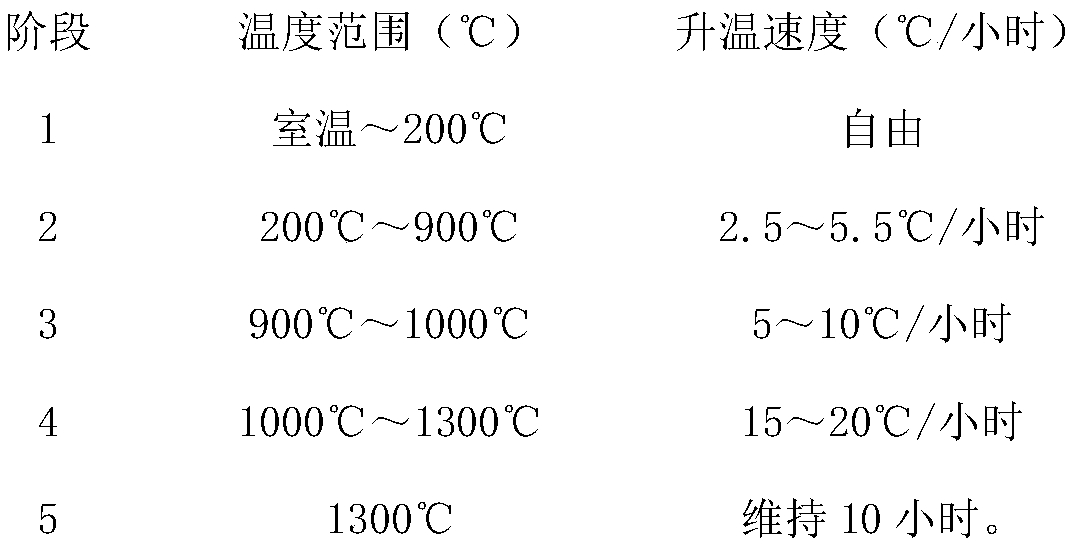

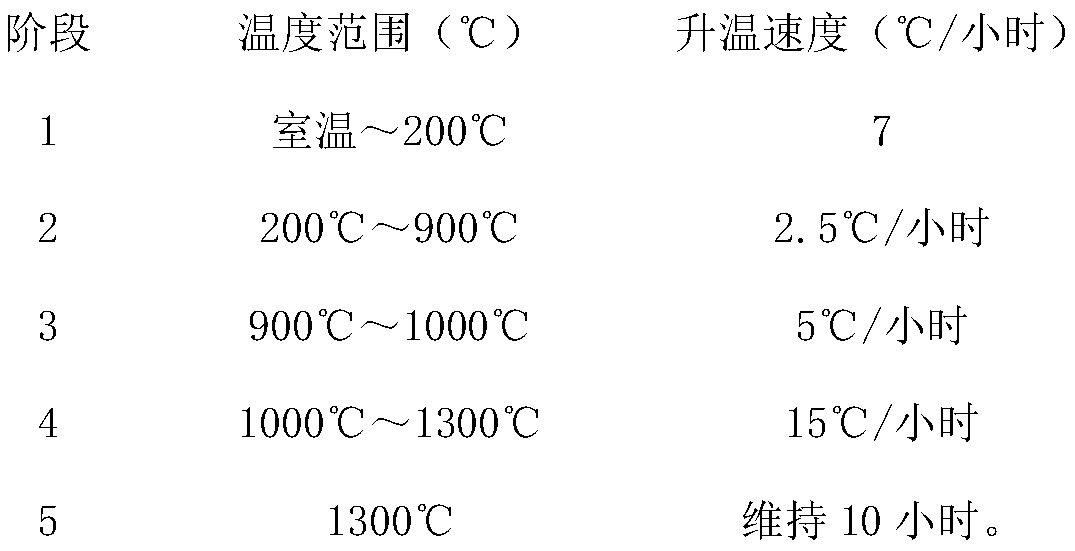

[0048] This embodiment provides a method for preparing an ablation-resistant carbon material, the method comprising the following steps:

[0049] 1) Mix ultrafine coke powder with a particle size below 10 μm, graphite powder with a particle size below 50 μm, and pitch coke powder with a particle size below 50 μm to obtain a mixture; wherein: the total weight of the mixture is 100% Calculated, the three components are mixed according to the following weight percentages in the mixture: the content of superfine coke powder is 70wt%, pitch coke powder is 20wt%, graphite powder 10wt%;

[0050] 2) Add medium-temperature asphalt with a softening point of 93°C and a carbon residue rate of 40wt% to the mixture obtained in step 1) according to 45wt% of the total mixture, knead for 3 hours until the material temperature reaches 160°C, and then roll at 130°C , the thickness of the rolled sheet is less than 2 mm, and the rolled sheet is cooled and then crushed and ground to a particle size...

Embodiment 2

[0065] The difference between this embodiment and Example 1 is that each raw material formula is different, specifically: the total weight of the mixture is 100% in the present embodiment step 1), and the three components are mixed according to the following weight percentages in the mixture: The content of fine coke powder is 70wt%, graphite powder is 5wt%, and pitch coke powder is 25wt%. In step 2), pitch is added by 50wt% of the total mixture.

[0066] The product density that present embodiment obtains is 1.87g / cm , Shore hardness 53, degree of graphitization 88%

Embodiment 3

[0068] The difference between this embodiment and Example 1 is that each raw material formula is different, specifically: the total weight of the mixture is 100% in the present embodiment step 1), and the three components are mixed according to the following weight percentages in the mixture: The content of fine coke powder is 65wt%, graphite powder is 15wt%, and pitch coke powder is 20wt%. In step 2), pitch is added by 40wt% of the total mixture.

[0069] The product density that present embodiment obtains is 1.83g / cm 3 , Shore hardness 51, graphitization degree 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com