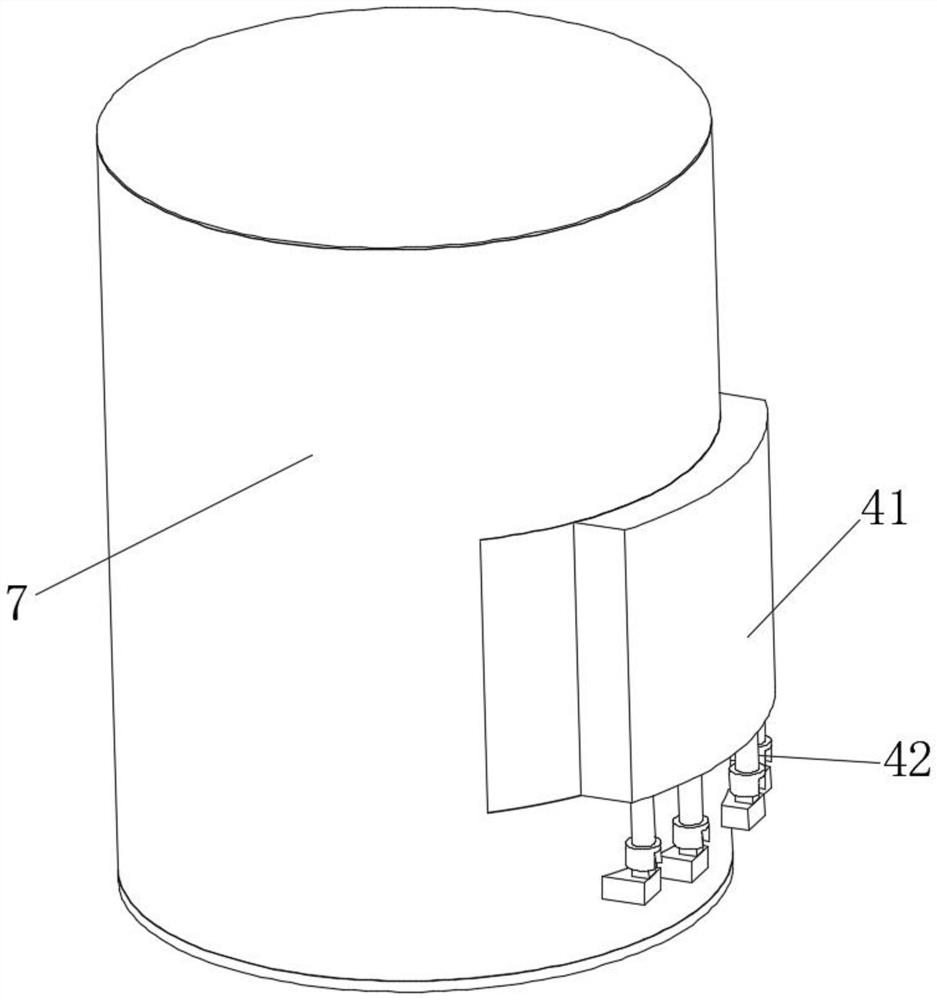

Knee joint posterior cruciate ligament tibial insertion avulsion fracture bone fracture plate 3D printing device

A cruciate ligament, avulsion fracture technology, applied in the field of 3D printing, can solve the problems of inability to tilt, limited application scope, inability to print, etc., to achieve the effect of convenient operation and expanded application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

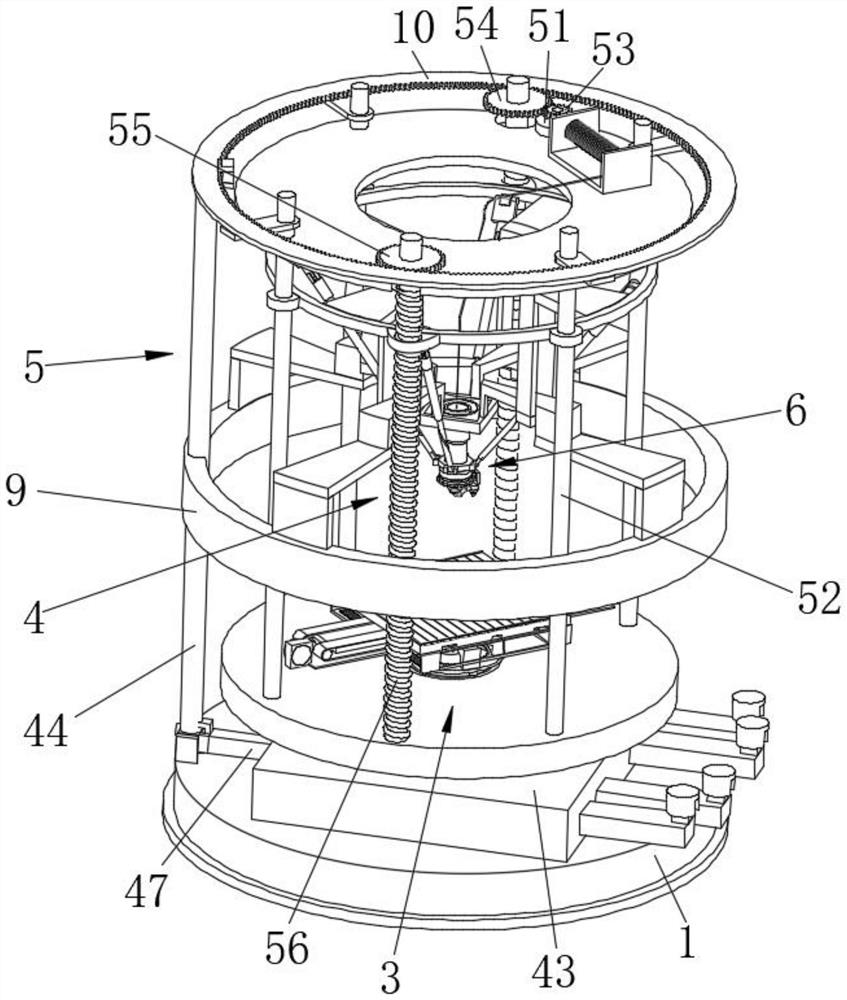

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

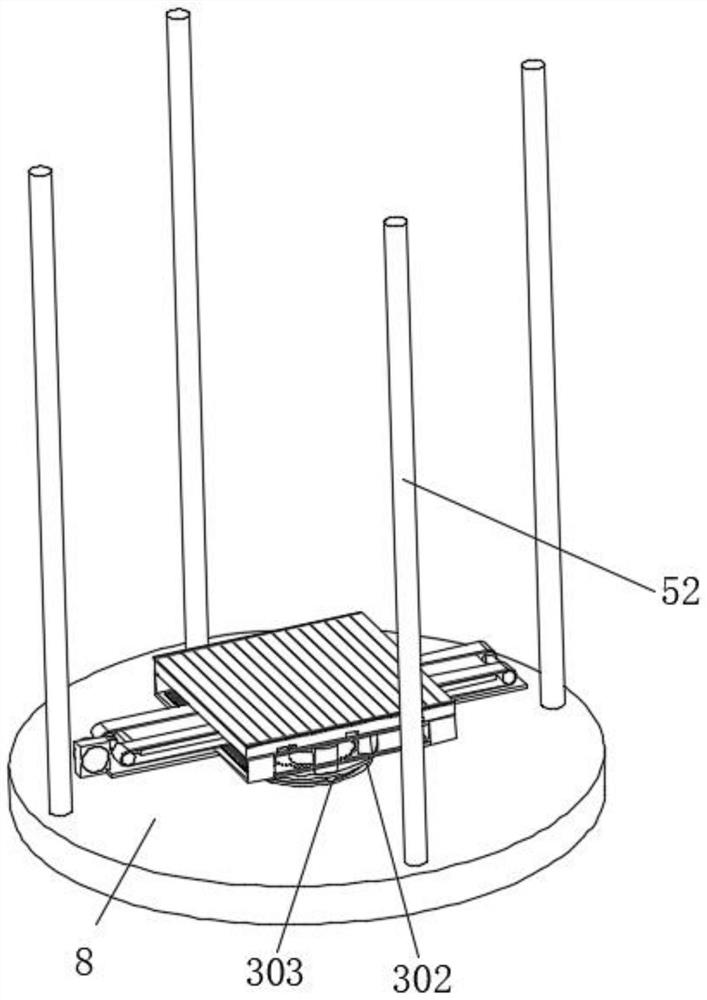

[0031] like figure 1 and figure 2 As shown, the 3D printing device of the knee joint posterior cruciate ligament tibial avulsion fracture bone plate in this embodiment consists of a base 1, a placing plate 2, a first support block 43, a first support plate 8, an adjustment component 3, and a support ring 9 , the first ring gear 10, the self-locking assembly 4, the moving assembly 5, the first supporting frame 11, the first motor 12, the first sleeve 14, the second sleeve 15, the sliding rod 16, the first connecting frame 18 and the spraying The components 6 are connected to form.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com