Covered stent

A covering stent and covering technology, which can be applied to stents, blood vessels, and devices of human tubular structures, etc., can solve problems such as burrs at the edges of coverings, and achieve the effect of reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

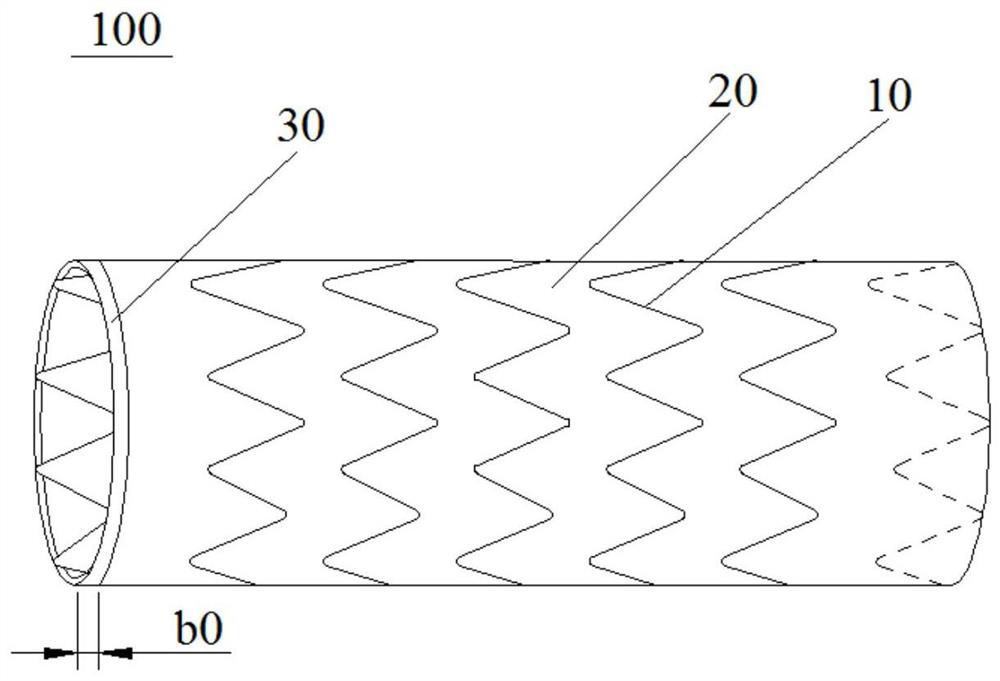

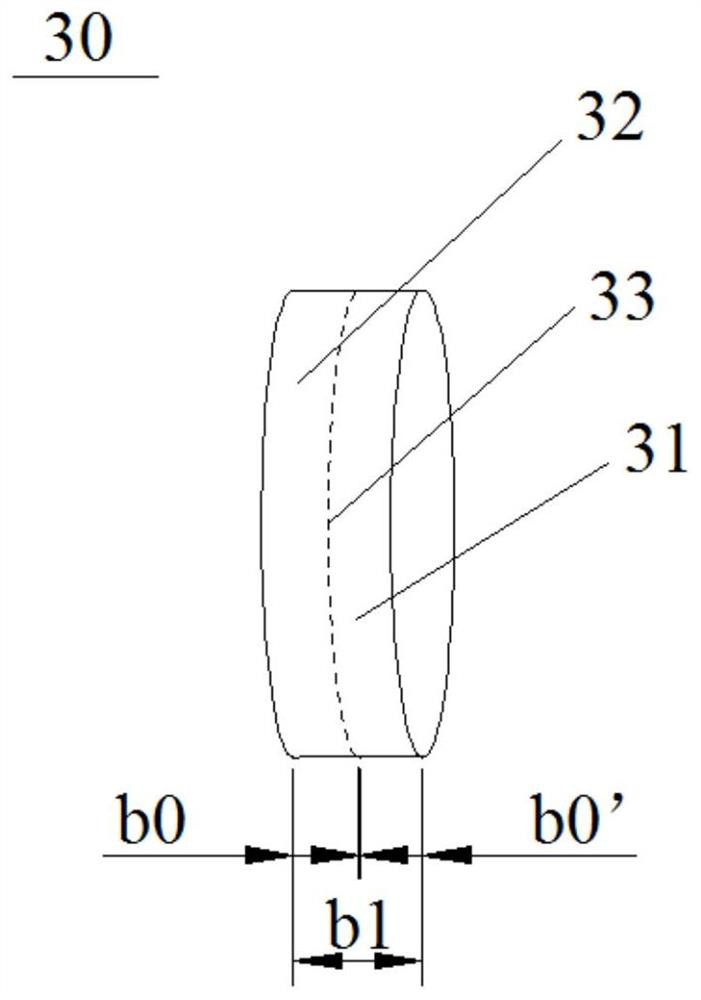

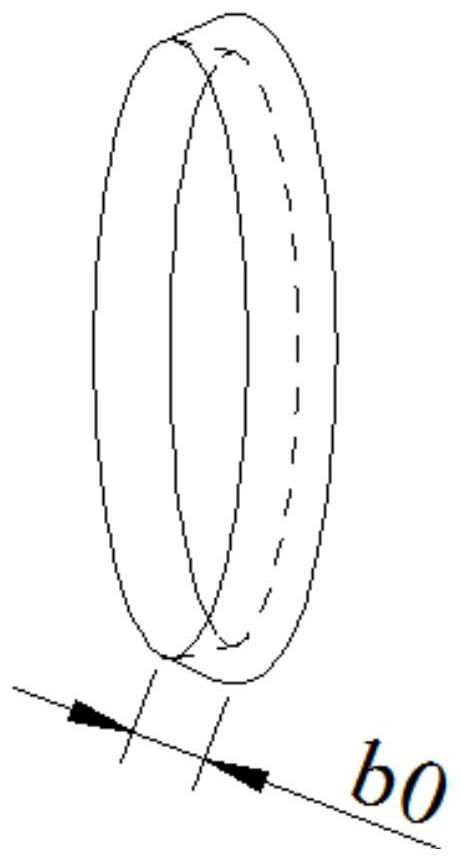

[0044] combine Figure 1 to Figure 3As shown, the stent graft 100 of this embodiment includes a plurality of wave coils 10 , a covering film 20 and a restraining member 30 . A plurality of wave coils 10 are arranged in the axial direction, thereby forming a skeleton for supporting the coating film 20 . The covering film 20 is disposed on the plurality of wave coils 10 , and the covering film 20 and the plurality of wave coils 10 form a hollow tubular structure with two open ends, at least one open edge of the hollow tubular structure is provided with a binding member 30 . The part is covered by the restraining member 30 , and the pore size of the restraining member 30 is smaller than the wire diameter of the coating film 20 . The wave ring 10 is a metal wave ring, which has better support and deformability. The coating 20 is woven from a wire, and the coating 20 of the present embodiment is a PET coating woven by yarn. The binding member 30 can be made of PET, PTFE or other...

Embodiment approach 2

[0053] combine Figure 4 to Figure 6 As shown, the stent graft 100 of this embodiment includes a plurality of wave coils 10 , a covering film 20 and a restraining member 30 . A plurality of wave coils 10 are arranged in the axial direction, thereby forming a skeleton for supporting the coating film 20 . The covering film 20 is disposed on the plurality of wave coils 10 , the covering film 20 and the plurality of wave coils 10 form a hollow tubular structure with openings at both ends, at least one open edge of the hollow tubular structure is provided with a binding member 30 , and the end of the covering film 20 is It is covered by the binding member 30 , and the pore size of the binding member 30 is smaller than the wire diameter of the coating film 20 . The restraint member 30 of the present embodiment includes a plurality of restraint units 40, the plurality of restraint units 40 are arranged at intervals at the opening of the at least one end of the hollow tubular structu...

Embodiment approach 3

[0062] combine Figure 9 and Figure 10 As shown, the stent graft 100 of this embodiment includes a plurality of wave coils 10 , a covering film 20 and a restraining member 30 . A plurality of wave coils 10 are arranged in the axial direction, thereby forming a skeleton for supporting the coating film 20 . The covering film 20 is disposed on the plurality of wave coils 10 , the covering film 20 and the plurality of wave coils 10 form a hollow tubular structure with openings at both ends, at least one open edge of the hollow tubular structure is provided with a binding member 30 , and the end of the covering film 20 is It is covered by the binding member 30 , and the pore size of the binding member 30 is smaller than the wire diameter of the coating film 20 .

[0063] According to the stent graft 100 of the present application, by arranging a strip 34 at the opening of at least one end of the hollow tubular structure formed by the membrane 20 and the plurality of wave coils 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com