High-temperature-resistant modified filter membrane

A high temperature resistant and modified technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems affecting membrane quality, human and environmental damage, tensile strength and thermal stability decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

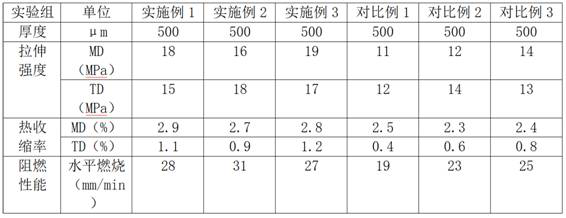

Examples

Embodiment 1

[0027] A high-temperature-resistant modified filter membrane comprises a polypropylene base membrane and a modified membrane, wherein the upper and lower sides of the polypropylene base membrane are respectively coated with a layer of modified membrane.

[0028] The raw materials of each component of the modified film are as follows, in parts by weight, including 50 parts of polyvinylidene chloride, 5 parts of ethylene-alkyl acrylate copolymer, 5 parts of benzophenone, 1 part of butyl lithium, 2 parts of 4-hydroxymethyl piperidine, 0.5 part of heat stabilizer, 1 part of dispersant, 5 parts of binder, 0.5 part of inorganic filler, and 2.5 parts of plasticizer.

[0029] The heat stabilizer is one or more mixtures of barium stearate, lithium stearate and epoxy stearate.

[0030] The plasticizer is one or two mixtures of dioctyl adipate and citrate.

[0031] The adhesive is one or a mixture of ethylene-vinyl acetate copolymer and copolymer of acrylic acid and acrylonitrile.

[0...

Embodiment 2

[0041] A high-temperature-resistant modified filter membrane comprises a polypropylene base membrane and a modified membrane, wherein the upper and lower sides of the polypropylene base membrane are respectively coated with a layer of modified membrane.

[0042] The raw materials of each component of the modified film are as follows, in parts by weight, including 55 parts of polyvinylidene chloride, 5 parts of ethylene-alkyl acrylate copolymer, 6 parts of benzophenone, 2 parts of butyl lithium, 3 parts of 4-hydroxymethyl piperidine, 0.7 parts of heat stabilizer, 2 parts of dispersant, 6 parts of binder, 0.7 part of inorganic filler, and 2.8 parts of plasticizer.

[0043] The heat stabilizer is one or more mixtures of barium stearate, lithium stearate and epoxy stearate.

[0044] The plasticizer is one or two mixtures of dioctyl adipate and citrate.

[0045]The adhesive is one or a mixture of ethylene-vinyl acetate copolymer and copolymer of acrylic acid and acrylonitrile.

...

Embodiment 3

[0055] A high-temperature-resistant modified filter membrane comprises a polypropylene base membrane and a modified membrane, wherein the upper and lower sides of the polypropylene base membrane are respectively coated with a layer of modified membrane.

[0056] The raw materials of each component of the modified film are as follows, in parts by weight, including 60 parts of polyvinylidene chloride, 6 parts of ethylene-alkyl acrylate copolymer, 7 parts of benzophenone, 3 parts of butyl lithium, 4 parts of 4-hydroxymethyl piperidine, 1 part of heat stabilizer, 3 parts of dispersant, 7 parts of binder, 1 part of inorganic filler, and 3 parts of plasticizer.

[0057] The heat stabilizer is one or more mixtures of barium stearate, lithium stearate and epoxy stearate.

[0058] The plasticizer is one or two mixtures of dioctyl adipate and citrate.

[0059] The adhesive is one or a mixture of ethylene-vinyl acetate copolymer and copolymer of acrylic acid and acrylonitrile.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com