Screening and impurity removing equipment for moxa processing and working method of screening and impurity removing equipment

A screening and moxa velvet technology, applied in chemical instruments and methods, sustainable manufacturing/processing, separating solids from solids with airflow, etc., can solve the problems of low screening efficiency, poor automation, large material loss, etc. problems, to avoid poor screening effect, reduce material loss, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

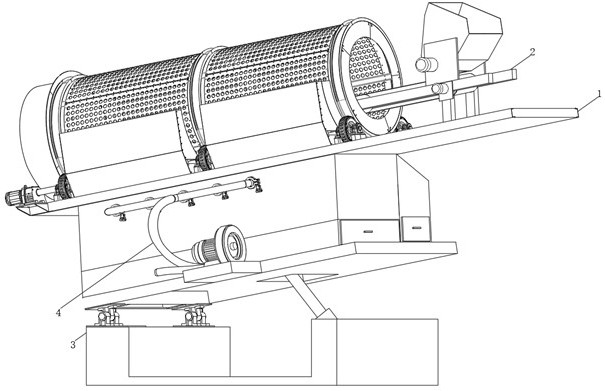

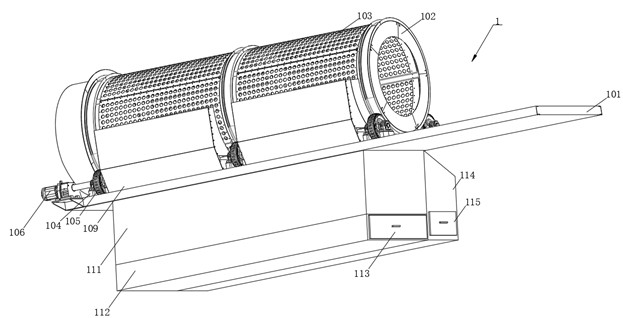

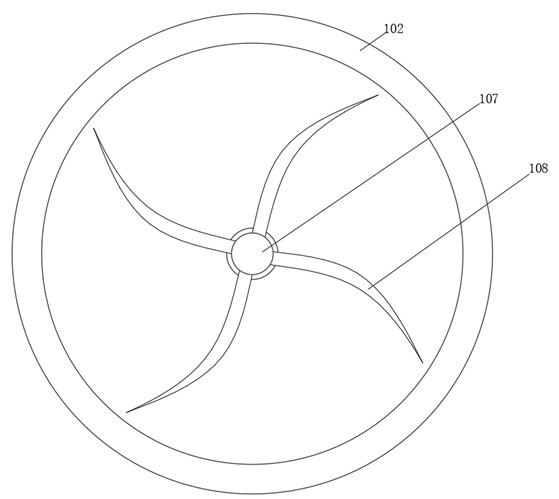

[0038] like Figure 1-Figure 10 As shown, a screening and impurity removal equipment for moxa velvet processing includes a screening assembly 1, a feeding assembly 2, an adjusting assembly 3 and a separation assembly 4, and the feeding assembly 2 is installed at one end of the screening assembly 1, and adjusts the The component 3 is fixed below the screening component 1, and the separation component 4 is fixed above one side of the adjustment component 3. The screening component 1 includes a base 101, a screening drum 102, four side plates 109 and a rotating drum 110. The dividing cylinder 102 rotates above the base 101, and four side plates 1 109 are located on both sides of the sieving cylinder 102 in pairs. A rotating drum 110 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com