Water chestnut grading and automatic boxing device

A technology of automatic boxing and water chestnuts, applied in packaging, solid separation, chemical instruments and methods, etc., can solve the problems of water chestnut extrusion damage, low screening efficiency, poor screening effect, etc., to improve the classification rate, The effect of increasing forward speed and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

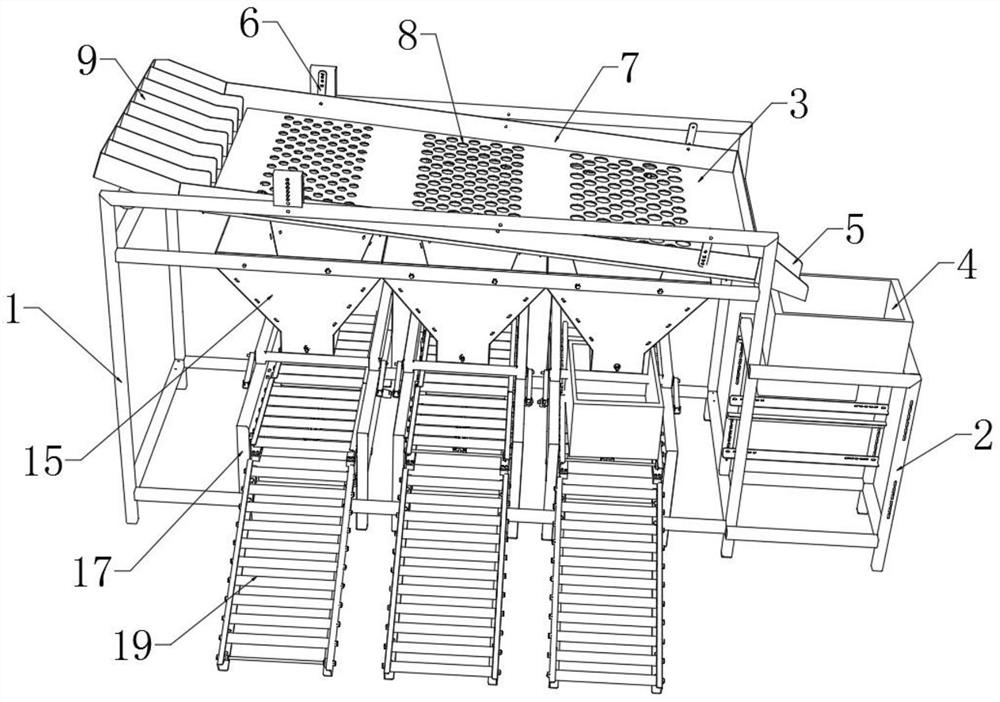

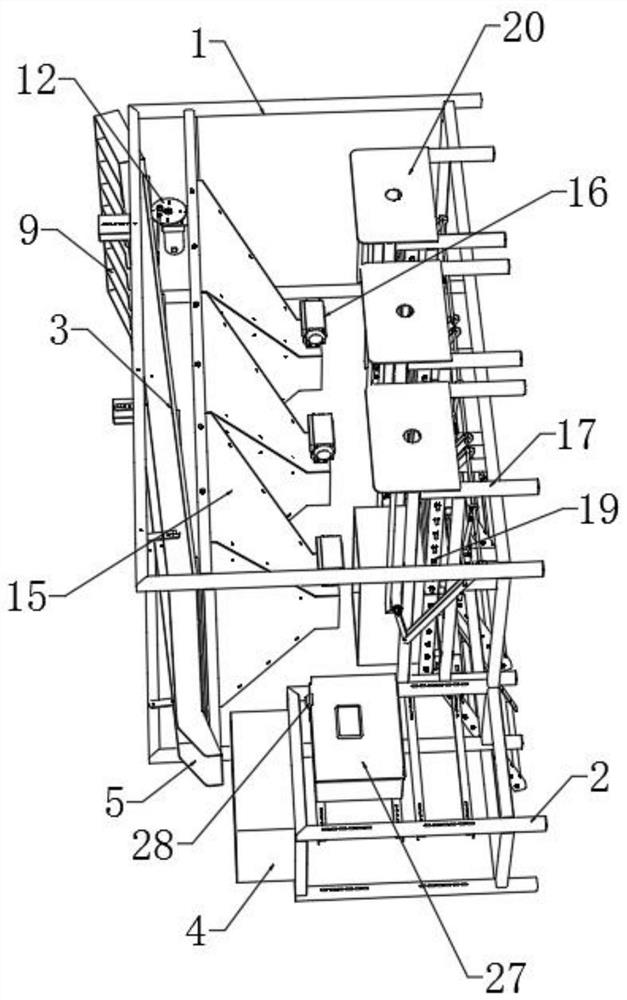

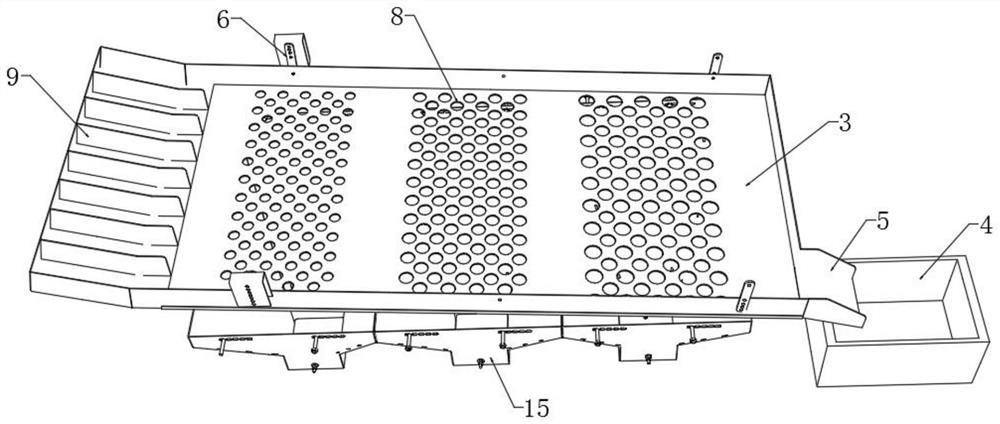

[0034] see Figure 1-10, the present invention provides a technical solution: a water chestnut grading automatic packing device, comprising a frame 1, a vibration grading component, three collecting components and three weighing control components, and the vibration grading component is installed at the top of the frame 1, Three collection components are installed side by side on the rack 1, and the collection components are arranged correspondingly with the vibration grading components, three weighing control components are installed side by side on the inner bottom of the rack 1, and the weighing control components are arranged corresponding to the collection components;

[0035] The vibration grading assembly includes a mounting bracket 2, a sieve plate 3, a storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com