Automatic leveling lifting appliance suitable for multi-dimensional operation working conditions and automatic leveling method

A technology for automatic leveling and operating conditions, applied in the field of spreaders, can solve the problems of low efficiency of lifting objects and low device replacement efficiency, and achieve the effects of increasing stability, improving efficiency, and improving replacement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

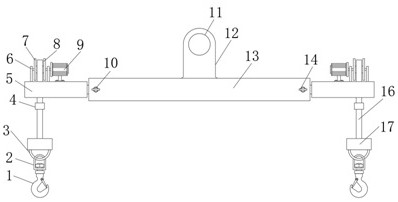

Embodiment 1

[0034] Embodiment 1: An automatic leveling spreader adapted to multi-dimensional operating conditions, including a support member for connecting a crane, a spreader member is installed on the support member, the spreader member is used for hoisting objects, and the spreader member includes adjustment. Components, spreader components used to connect objects, and detection components used to detect the tensile force of the spreader components. When the detection component detects that the tensile force of the spreader components is greater than the preset value, the adjustment component adjusts the length of the spreader components to make the length of the spreader components. Extend, when the detection component detects that the tension of the spreader component is less than the preset value, the adjustment component adjusts the length of the spreader component to shorten the length of the spreader component;

[0035] A connecting member is installed between the support member ...

Embodiment 2

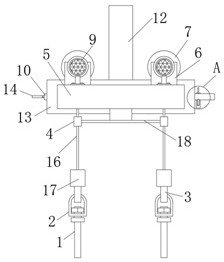

[0036] Embodiment 2: an automatic leveling spreader adapted to multi-dimensional operating conditions, including a support member for connecting a crane, a spreader member is installed on the support member, the spreader member is used for hoisting objects, and the spreader member includes adjustment. Components, spreader components used to connect objects, and detection components used to detect the tensile force of the spreader components. When the detection component detects that the tensile force of the spreader components is greater than the preset value, the adjustment component adjusts the length of the spreader components to make the length of the spreader components. Extend, when the detection component detects that the tension of the spreader component is less than the preset value, the adjustment component adjusts the length of the spreader component to shorten the length of the spreader component;

[0037] A connecting member is installed between the support member ...

Embodiment 3

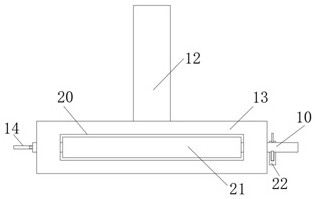

[0042] An automatic leveling spreader adapted to multi-dimensional operating conditions, comprising a support member for connecting a crane, a spreader member is mounted on the support member, the spreader member is used for hoisting objects, and the spreader member includes an adjustment component, used for The spreader component connected to the object and the detection component used to detect the tensile force of the spreader component. When the detection component detects that the tension of the spreader component is greater than the preset value, the adjustment component adjusts the length of the spreader component to extend the length of the spreader component. When it is detected that the pulling force of the spreader assembly is less than the preset value, the adjustment assembly adjusts the length of the spreader assembly to shorten the length of the spreader assembly;

[0043] A connecting member is installed between the support member and the spreader member, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com