Soft soil curing agent, method for curing soft soil and application of soft soil curing agent

A technology of curing agent and soft soil, which is applied in the field of curing soft soil and soft soil curing agent, can solve the problems of high cost and poor curing effect of soft soil in the Pearl River Delta, and achieve low cost, poor solution effect and relatively low cost high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0052] Embodiment 2 of the present application provides a method for the second group of soft soil curing agents to solidify soft soil, including the following steps: doping the soft soil with 3% metakaolin / 3 water glass / 12% cement, 3% metakaolin, respectively Kaolin / 5 silicate / 12% cement, 3% metakaolin / 7 silicate / 12% cement, 5% metakaolin / 3 silicate / 12% cement, stir evenly, and then control the curing temperature as 18 DEG C to 22 DEG C, humidity of 95%, curing for 3 days, 7 days, 14 days, 28 days and 60 days to obtain a soft soil curing agent for curing soft soil.

Embodiment 3

[0054] Embodiment 3 of the present application provides a method for the third group of soft soil curing agents to solidify soft soil, including the following steps: doping the soft soil with 5% metakaolin / 3 water glass / 12% cement, 5% metakaolin, and 5% metakaolin, respectively. Kaolin / 5 silicate / 12% cement, 5% metakaolin / 7 silicate / 12% cement, stir well, and then control the curing temperature to be 18℃~22℃, humidity 95%, curing for 3 days, 7 days, 14 days, 28 days and 60 days to obtain the soft soil curing agent to solidify the soft soil.

Embodiment 4

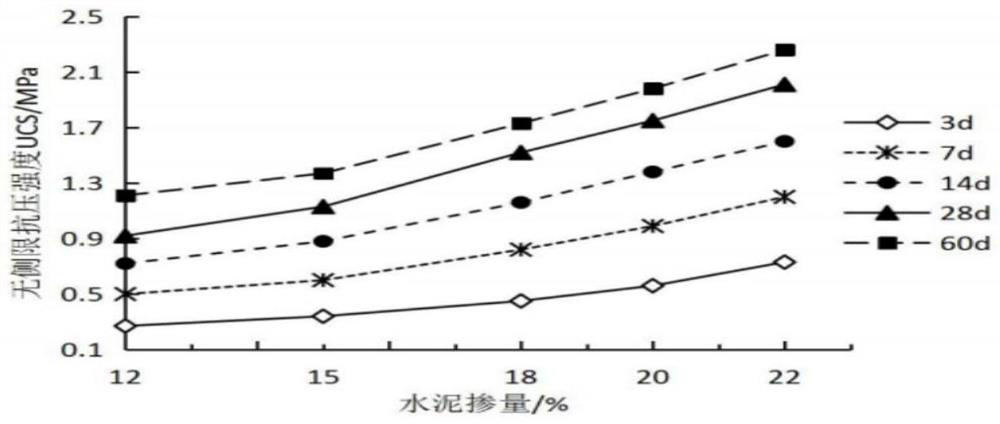

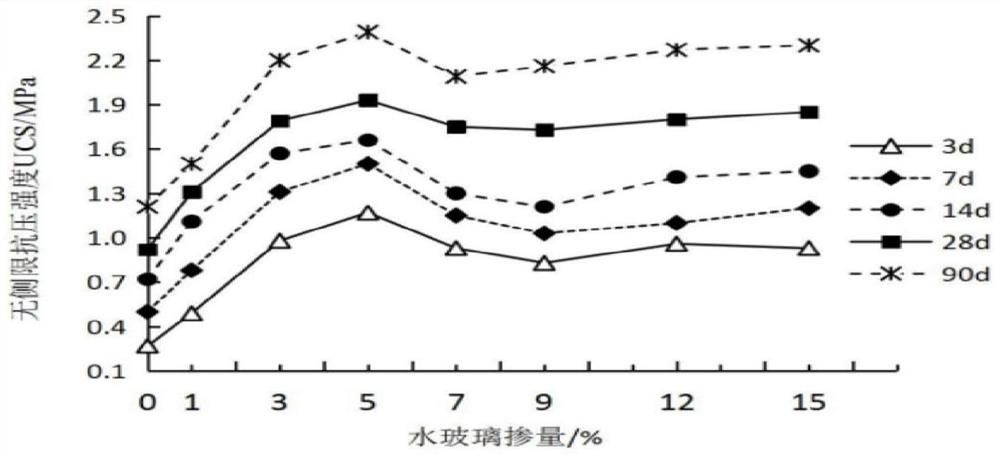

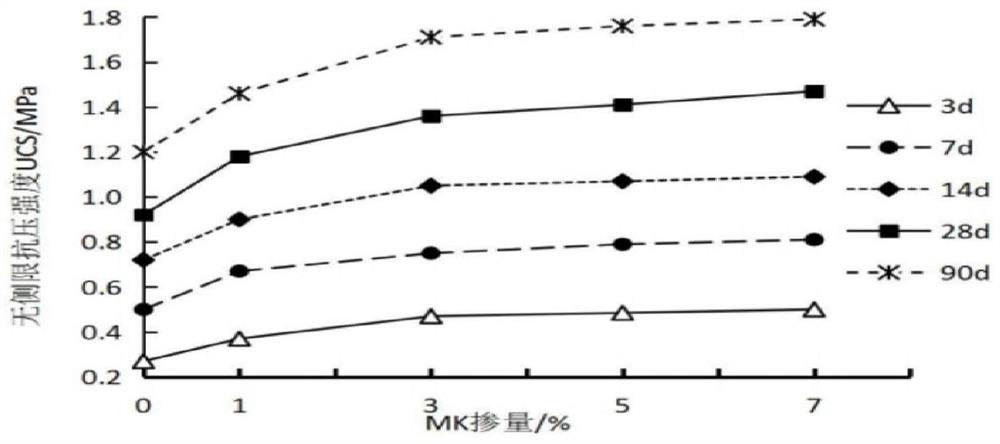

[0056] This Example 4 is to test the unconfined compressive strength of the solidified soft soil prepared in Comparative Examples 1 to 3, and the results are as follows Figure 1-3 shown, from Figure 1-3 It can be seen that the unconfined compressive strengths of the cement-solidified soft soil obtained after curing for 3 days, 7 days, 14 days, 28 days and 60 days are 0.2Mpa and 0.5Mpa respectively. , 0.7Mpa, 0.9Mpa and 1.2Mpa, and on the basis of 12% doped cement, further doping with water glass or metakaolin can further improve the curing effect. The unconfined compressive strength of the cured soft soil can reach about 2.35Mpa, and the addition of a small amount of metakaolin can achieve a better curing effect in a short curing time of the cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com