Pulverized coal forming method for solving long-distance transportation problem of low-metamorphic bituminous coal

A technology of long-distance transportation and molding method, which is applied in the field of railway transportation to achieve the effect of solving long-distance transportation, high molding rate and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

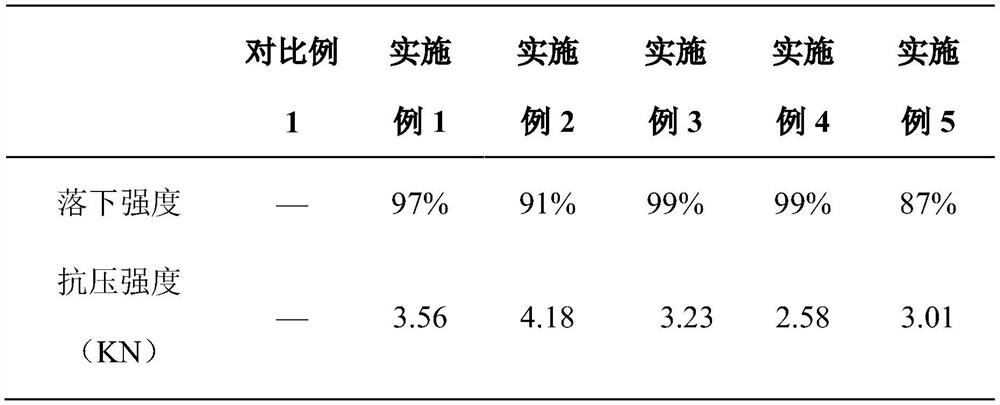

Embodiment 1

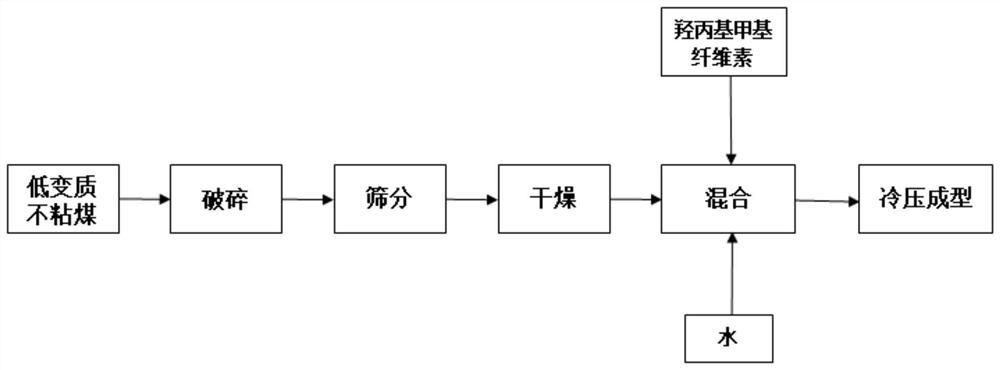

[0021] like figure 1 As shown, a pulverized coal molding method to solve the problem of long-distance transportation of low metamorphic bituminous coal includes the following steps:

[0022] Step 1, crushing, screening and drying the low metamorphic non-caking coal;

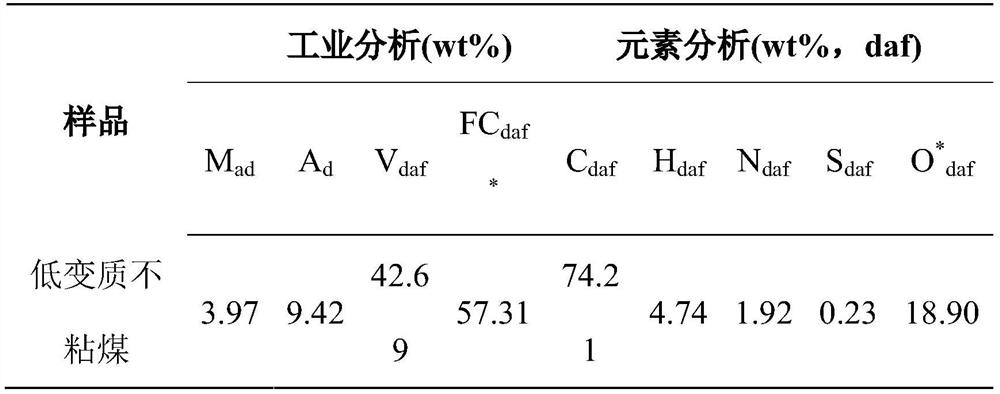

[0023] Step 2: Take 85wt% Fugu non-sticky coal and 6wt% hydroxypropyl methylcellulose and mix them in a beaker according to weight percentage, add 9wt% water after mixing evenly, fully stir and mix, pack Put it into the mold and place it under the pressure of 30MPa for cold pressing, and press for 5 minutes to get cylindrical briquettes Each briquette weighs about 12g.

Embodiment 2

[0025] like figure 1 As shown, a pulverized coal molding method to solve the problem of long-distance transportation of low metamorphic bituminous coal includes the following steps:

[0026] Step 1, crushing, screening and drying the low metamorphic non-caking coal;

[0027] Step 2: Take 85wt% Fugu non-sticky coal and 6wt% hydroxypropyl methylcellulose and mix them in a beaker according to weight percentage, add 9wt% water after mixing evenly, fully stir and mix, pack After entering the mold, place it under a pressure of 40MPa and cold press it to form a cylindrical shaped coal after pressing for 10 minutes Each briquette weighs about 12g.

Embodiment 3

[0029] like figure 1 As shown, a pulverized coal molding method to solve the problem of long-distance transportation of low metamorphic bituminous coal includes the following steps:

[0030] Step 1, crushing, screening and drying the low metamorphic non-caking coal;

[0031] Step 2: Take 88wt% Fugu non-sticky coal and 3wt% hydroxypropyl methylcellulose and mix them in a beaker by weight percentage, add 9wt% water after mixing evenly, fully stir and mix, pack After entering the mold, place it under a pressure of 30MPa and cold press it to form a cylindrical shaped coal after pressing for 10 minutes Each briquette weighs about 12g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com