River and lake bottom mud ecological desilting integrated equipment and ecological desilting system

A sediment and ecological technology, applied in construction, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve problems such as increased load on dredging vessels, reduce load and enhance dredging The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

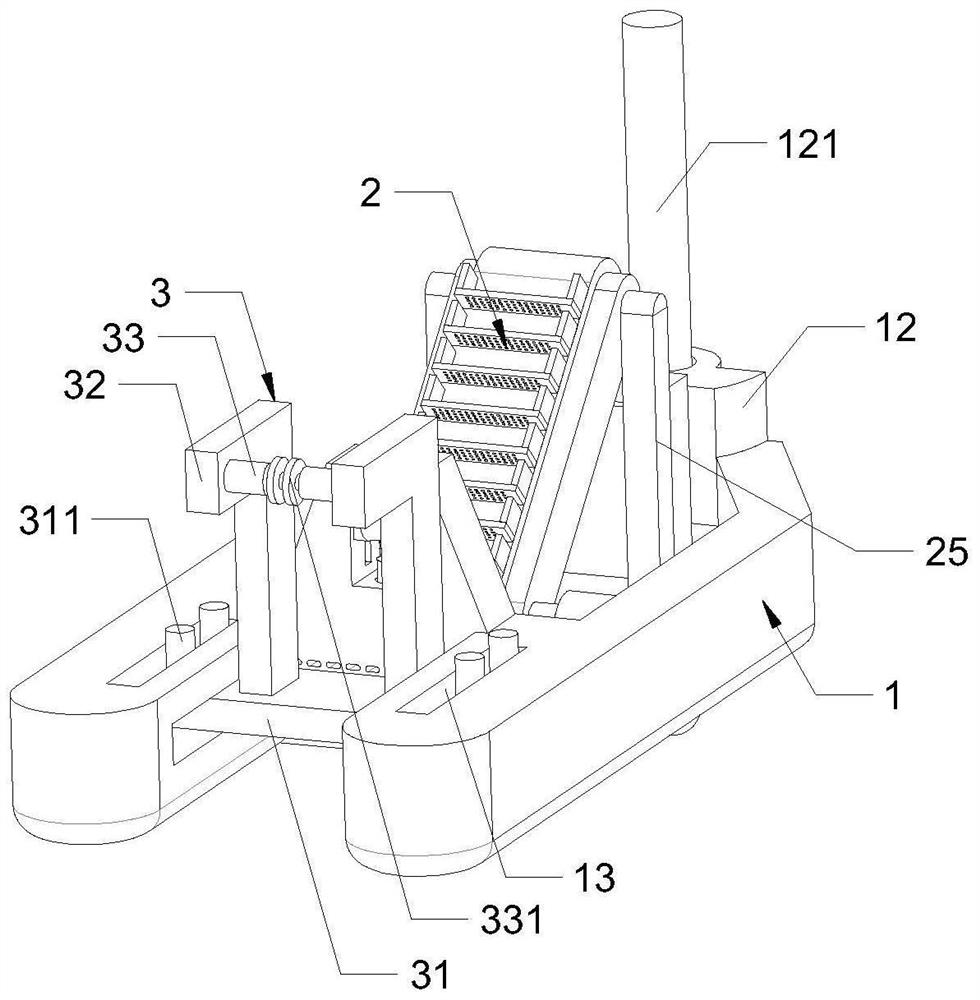

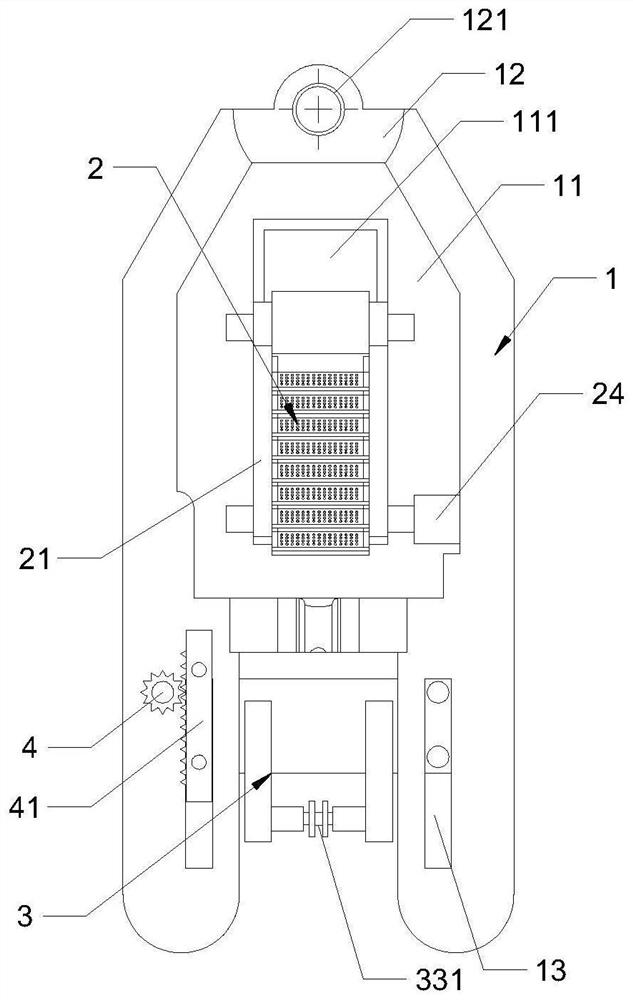

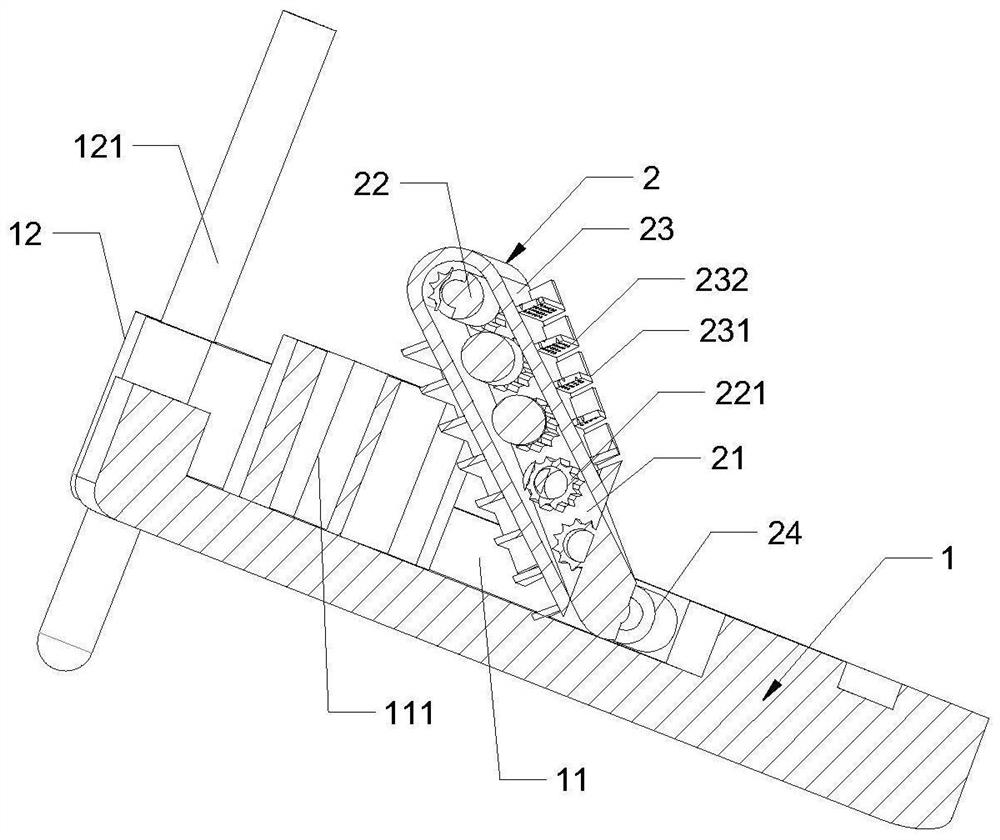

[0031] see Figure 1-Figure 5 , An integrated device for ecological dredging of river and lake bottom mud according to the present invention includes a dredging vessel body 1, and a support mechanism 3 is slidably connected to the upper end of the front end of the dredging vessel body 1; the dredging vessel body 1 The rear end is fixedly connected with a transmission mechanism 2; the transmission mechanism 2 is composed of a baffle 21, a rotating shaft 22, a conveyor belt 23 and a support column 25; the support column 25 is fixedly connected on both sides of the baffle 21; the rotating shaft 22 The conveyor belt 23 is rotatably connected to the rotating shaft 22 ; both sides of the rotating shaft 22 are fixedly connected with first gears 221 ; the first gears 221 are meshed and connected to On the inner wall of the conveyor belt 23; the two sides of the surface of the conveyor belt 23 are fixedly connected with bearing plates 231; the bearing plates 231 are fixedly connected w...

Embodiment approach

[0033] As an embodiment of the present invention, a limit plate 14 is fixedly connected to the middle surface of the dredging vessel body 1 ; a limit groove 141 is defined on the inner wall of the limit plate 14 ; the bottom surface of the limit plate 14 is A cylinder 142 is fixedly connected to the top; a support frame 15 is fixedly connected to the upper end of the cylinder 142 ;

[0034] When working, the support mechanism 3 is similar in structure to the traditional cutter suction dredger, and also has a reamer and a suction pipe arranged at the lower end of the reamer. The support frame 15 in the middle of the plate 14 can provide a certain support capacity for the suction pipe, and the cylinder 142 on the bottom surface of the limit plate 14 can drive the support frame 15 at the upper end to move up and down, so as to realize the adjustment of the angle of the outlet end of the suction pipe. , so that the angle between the point where the sludge falls and the inclined pl...

Embodiment 2

[0050] see Image 6 , Comparative Example 1, wherein another embodiment of the driving mechanism is that the driving mechanism is composed of a lead screw 42 and a ball nut 421; the lower end of the ball nut 421 is fixedly connected to the sliding rod 311; the ball nut 421 is rotatably connected to the lead screw 42.

[0051] During operation, the external third motor drives the lead screw 42 to rotate, and the lead screw 42 and the ball nut 421 fixedly connected to the sliding rod 311 rotate relative to the thread, so that the ball nut is driven by the third motor and the lead screw 42. 421 has the function of driving the bottom support mechanism 3 to move.

[0052] How it works: see Figure 1-Figure 5 , the structure of the dredging vessel body 1 is similar to that of the traditional cutter suction dredging vessel, wherein the front end of the dredging vessel body 1 is provided with a slidable support mechanism 3, and the supporting mechanism 3 can slide on the front end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com