Vibration damping device with clutch

A technology of a vibration damping device and a clutch, applied in the field of vehicles, can solve the problems of increasing the axial size of the shock absorber and increasing the production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

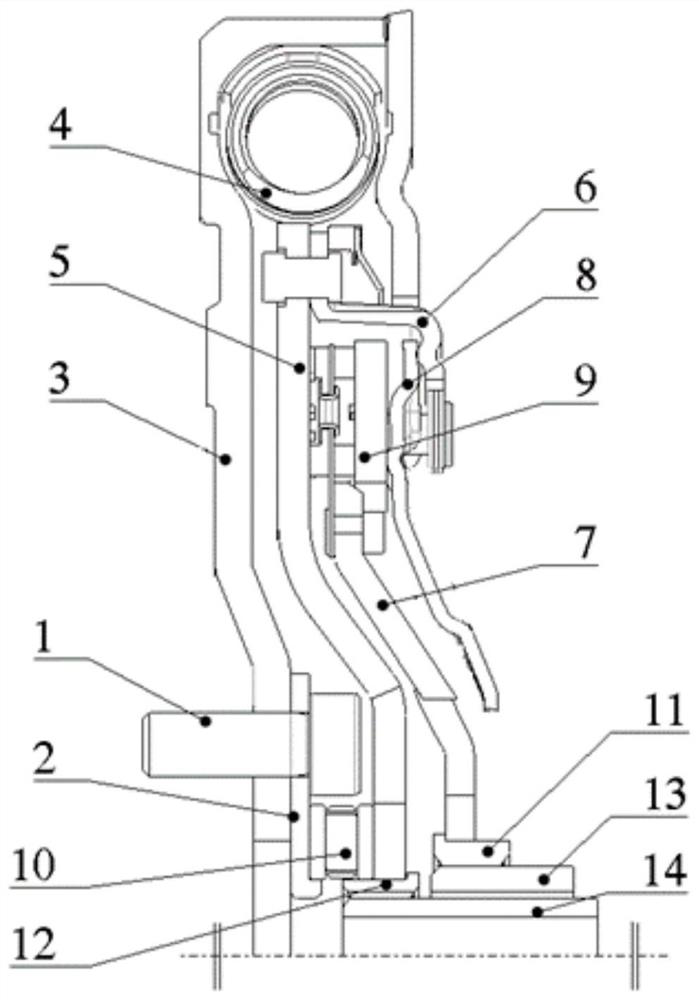

[0018] Specific embodiments of the vibration damping device according to the present invention will be described below with reference to the accompanying drawings. The following detailed description and accompanying drawings are used to illustrate the principles of the present invention by way of example, the present invention is not limited to the described preferred embodiments, and the protection scope of the present invention is defined by the claims.

[0019] According to an embodiment of the present invention, there is provided a damping device with a clutch, in other words, the damping device integrates the functions of the damper with the clutch. Such damping devices are used in the drive trains of various motor vehicles, and are especially suitable for hybrid vehicles.

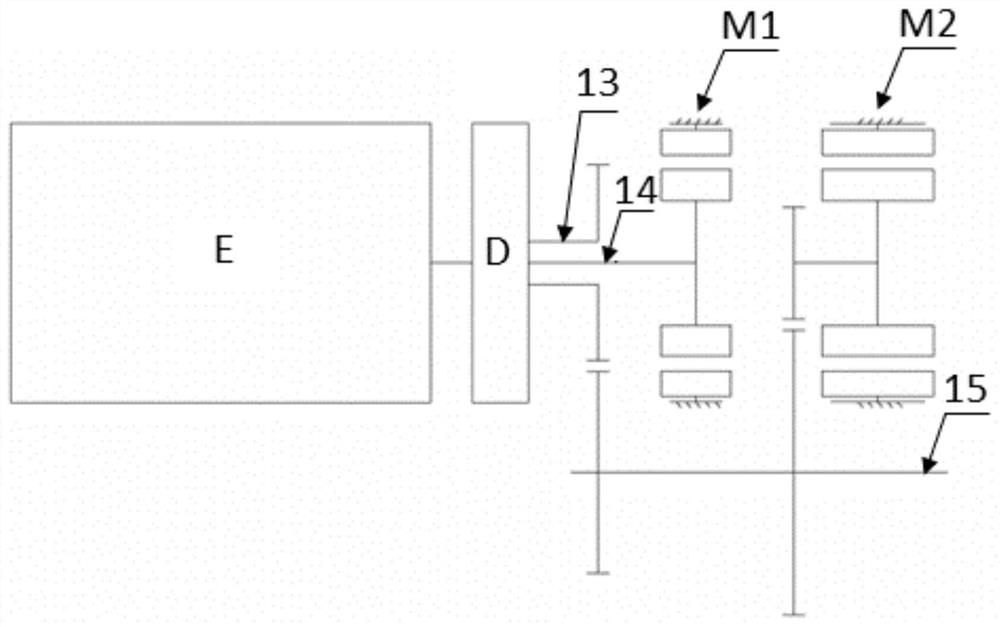

[0020] figure 1 The layout of the drive train to which the damping device D according to the embodiment of the invention is applied is schematically shown. like figure 1 As shown, the hybrid vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com