Ultrasonic phased array and TOFD (Time of Flight Diffraction) integrated automatic tracking scanning device for welding seam of U rib of steel bridge deck and top plate and welding seam defect detection method

An ultrasonic phased array and automatic tracking technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, measuring devices, and material analysis using sound waves/ultrasonic waves/infrasonic waves. It can solve the problem of low detection efficiency and inability to accurately evaluate , quality difficulty and other issues, to reduce the workload of testing personnel, improve the overall detection efficiency, improve the effect of computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

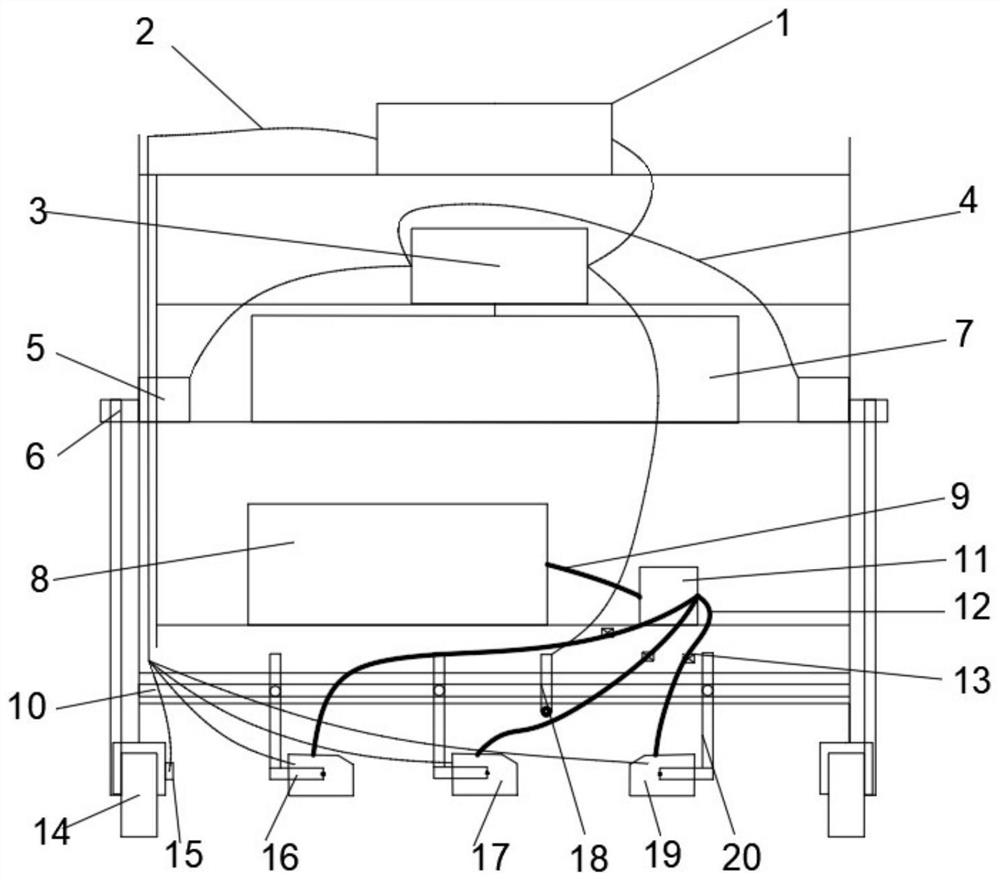

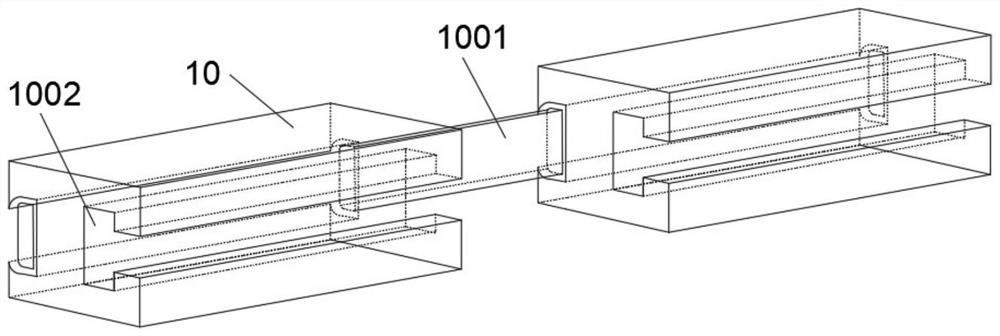

[0060] The technical solutions of the present invention will be explained in detail below with reference to the accompanying drawings and specific embodiments.

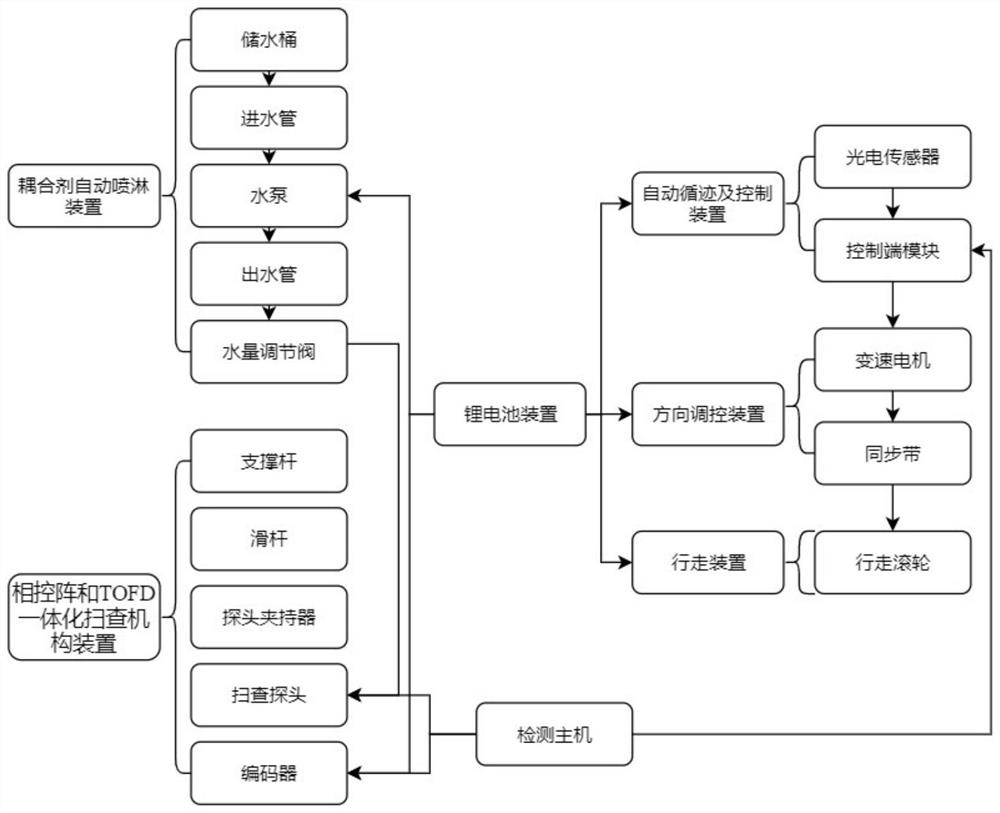

[0061] like Figure 1-3 As shown in the figure, an ultrasonic phased array and TOFD integrated automatic tracking scanning device for U-rib welds on the top plate of a steel bridge deck includes a traveling mechanism 14, an automatic tracking and control mechanism, a direction regulating mechanism, and an automatic couplant spraying mechanism. , Phased array and TOFD integrated scanning mechanism, detection host 1, lithium battery 7.

[0062] The traveling mechanism 14 may adopt a wheel type, a crawler type, or the like. In this embodiment, the walking mechanism 14 is a walking roller, which is arranged at the bottom of the device. In order to ensure the flexibility and stability of the movement of the device, the number of walking rollers is preferably four.

[0063] The direction regulating mechanism and the trave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com