High-power battery test system and test method

A battery testing, high-power technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of short discharge time and waste of high-rate discharge, so as to avoid idleness, reduce test costs, improve utilization and work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

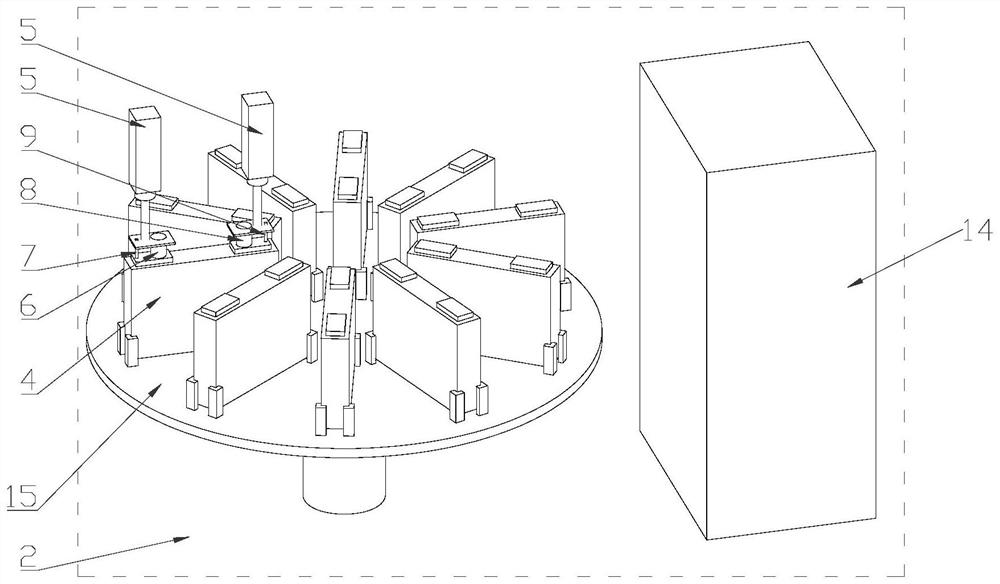

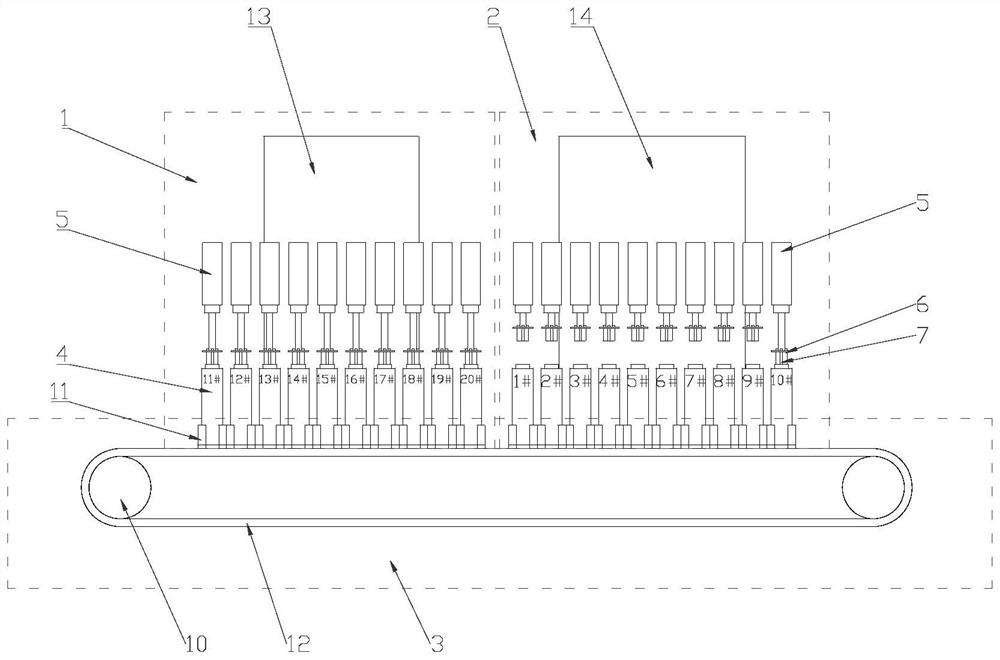

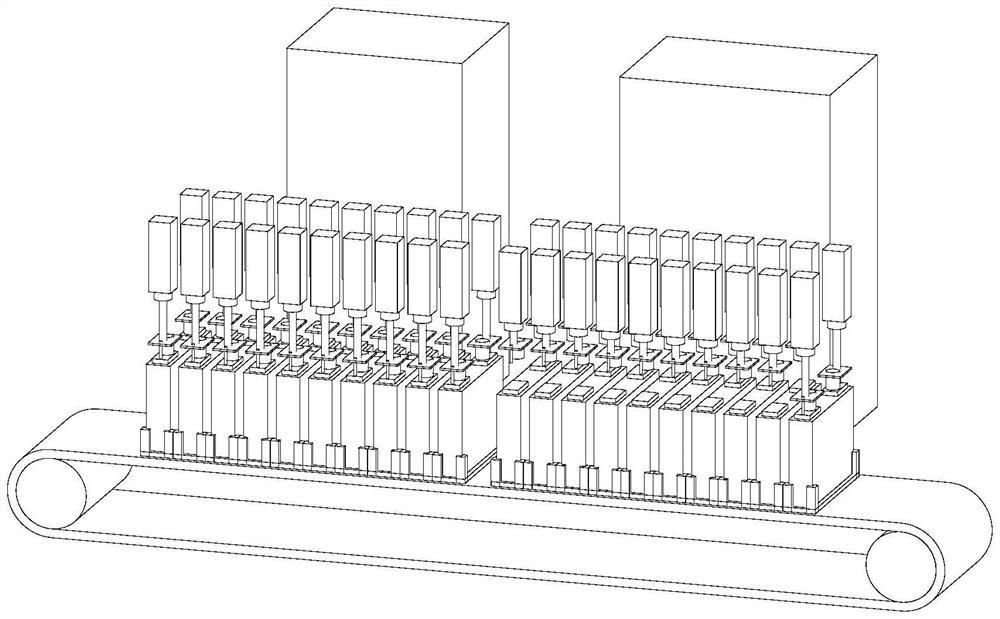

[0053] like Figure 1 to Figure 4 shown:

[0054] A high-power battery test system includes:

[0055] Charging sub-system 1 for charging M batteries and obtaining the charging data of each battery, where: M is a natural number greater than 1;

[0056] At the same time, at most M-1 batteries are discharged, and the discharge subsystem 2 that obtains the discharge data of this battery;

[0057] Accept the instruction issued by the central control sub-system, and send the battery charged by the charging sub-system to the transmission sub-system 3 in the discharging sub-system according to the instruction;

[0058] Sending working parameters to the charging subsystem and discharging subsystem, receiving the sampling data of the charging subsystem and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com