High-voltage side standby power supply automatic switching device based on PLC and automatic switching method of high-voltage side standby power supply automatic switching device

A backup power self-input, high-voltage side technology, applied in the direction of circuit devices, emergency power arrangements, electrical components, etc., can solve the safety hazards of stable operation of the power system, complex self-input lines, self-input efficiency, low stability, etc. Achieve the effect of simple connection lines, simple structure, and self-injection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

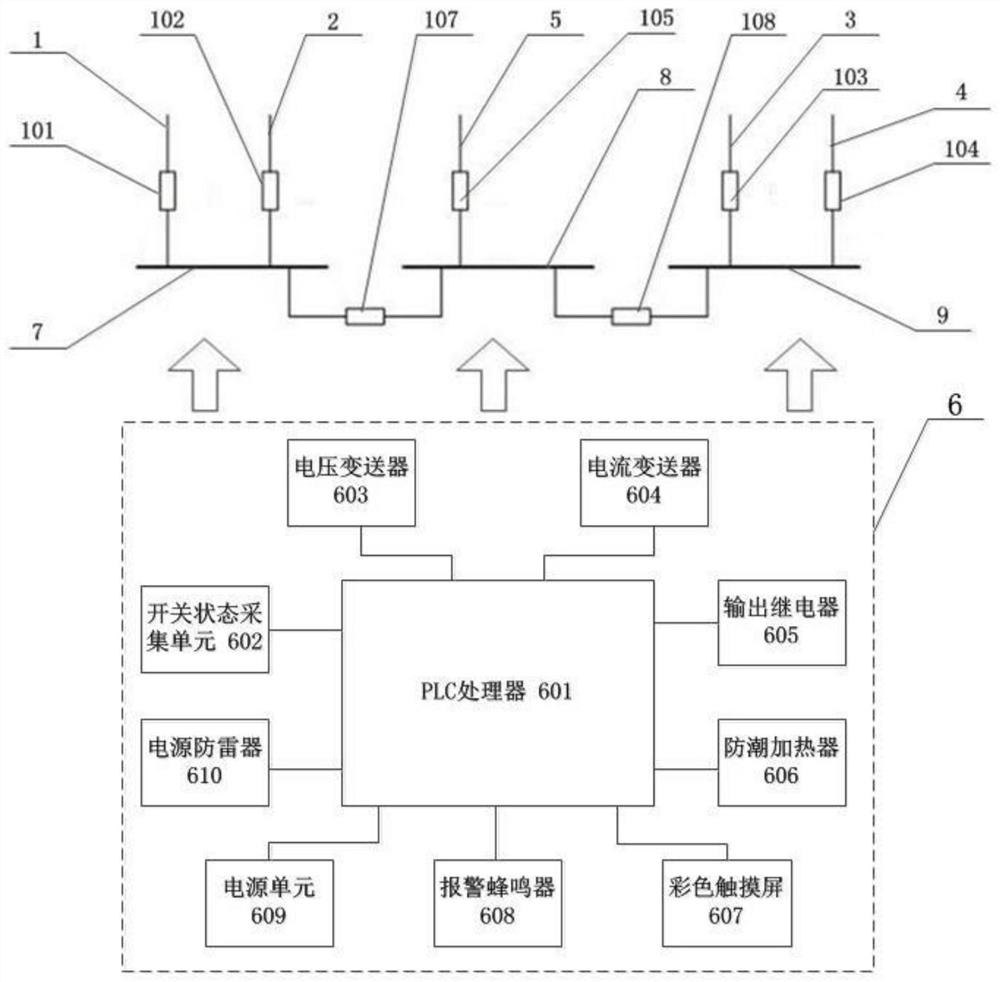

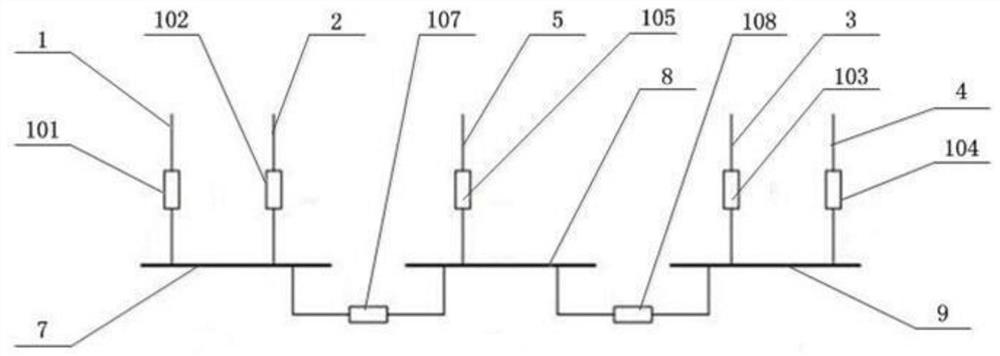

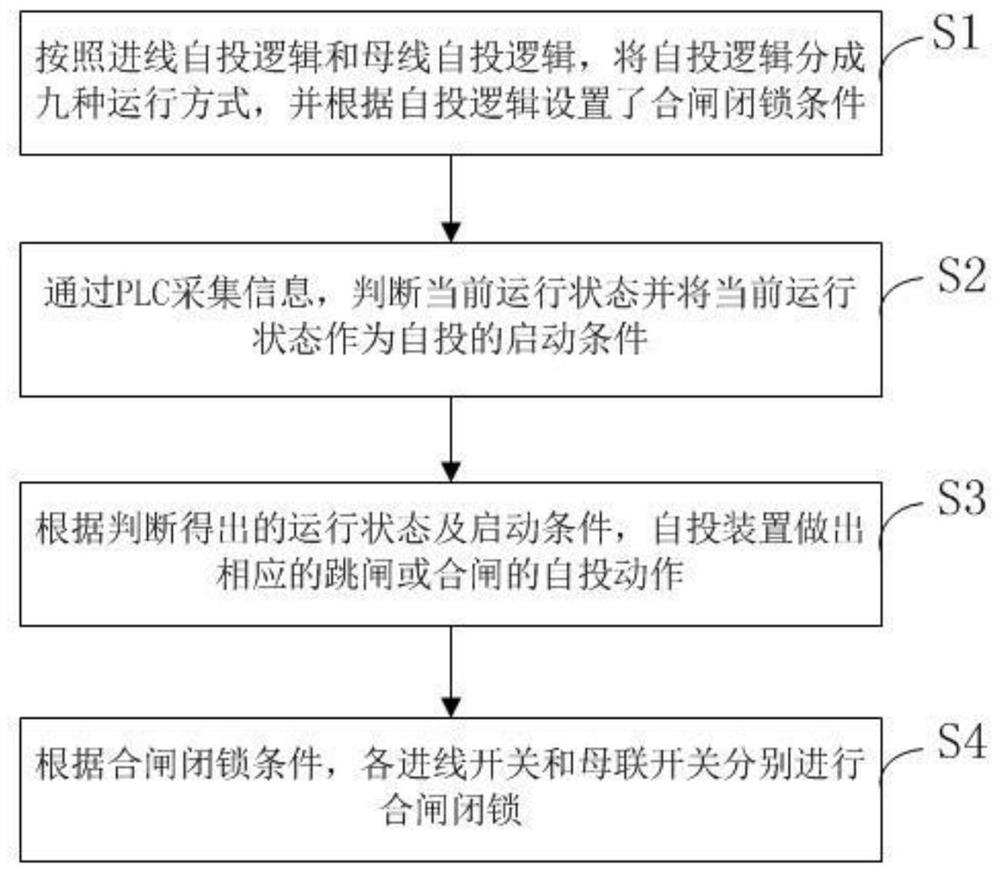

[0047] like Figure 1 to Figure 2 As shown, this embodiment provides a PLC-based high-voltage side standby power supply automatic switching device, including PLC6, first bus 7, second bus 8, third bus 9, first in-plant power supply line 1, second In-plant power supply line 2, third in-plant power supply line 3, fourth in-plant power supply line 4, fifth external power supply line 5, first incoming line switch 101, second incoming line switch 102, third incoming line Line switch 103, fourth incoming line switch 104, fifth incoming line switch 105, first bus tie switch 107, second bus tie switch 108, wherein PLC is a programmable logic controller, a For the digital operation controller of automatic control, the control instructions can be loaded into the memory for storage and execution at any time. PLC is the acronym of the English Programmable Logic Controller. PLC is widely used in various working conditions and is widely used. As the core of automatic switching control, PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com