Novel crawler belt self-propelled round bundle bundling machine

A self-propelled, baler technology, which is applied to tracked vehicles, packaging, motor vehicles, etc., can solve the problem of inconvenient dust and miscellaneous debris disposal, and achieve the effect of dust absorption and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1

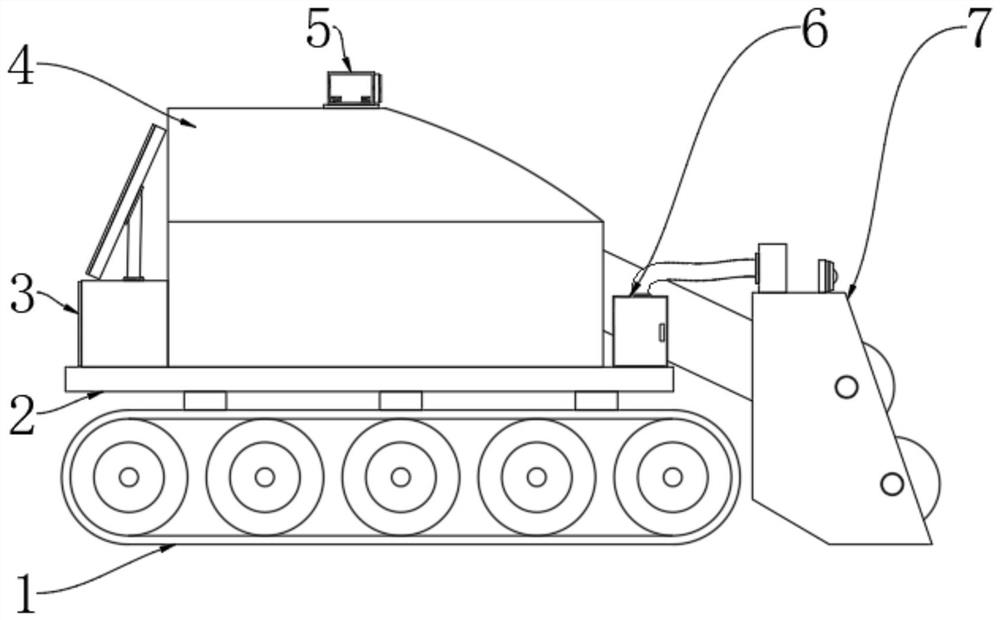

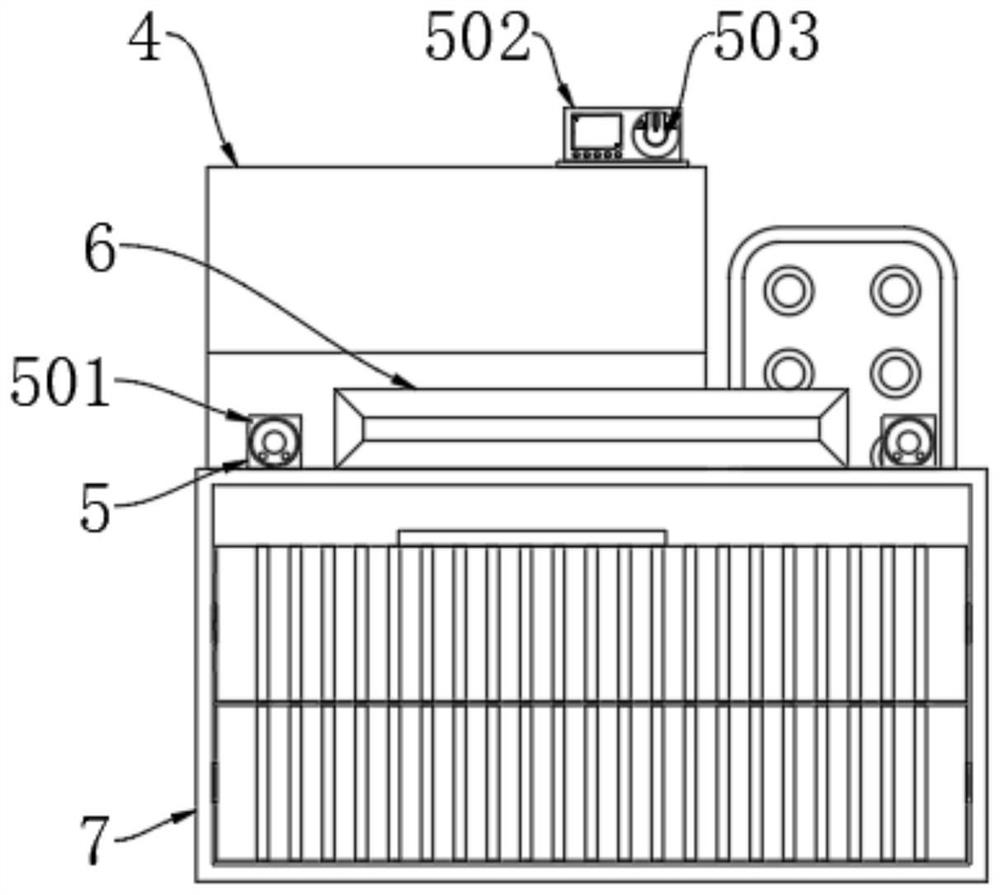

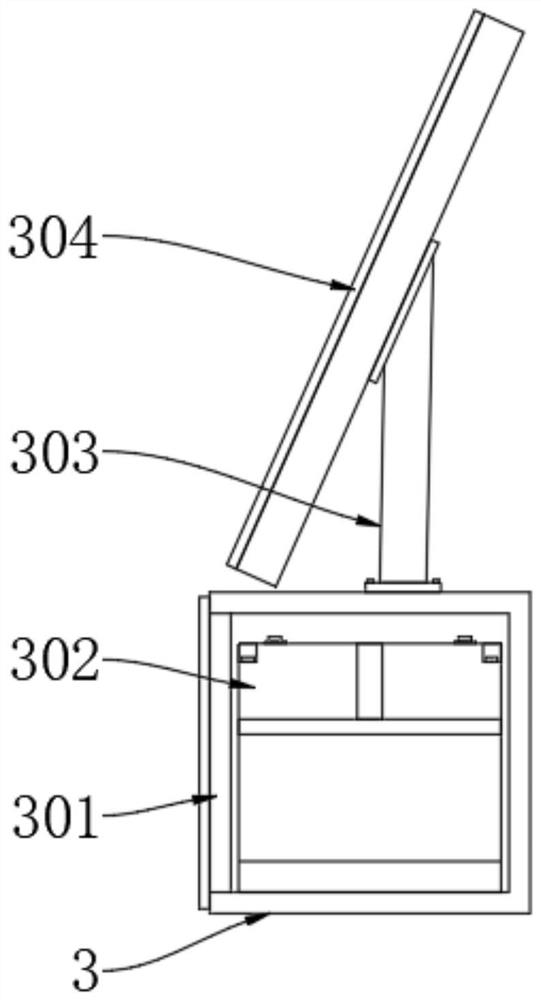

[0028] see Figure 1-5 , an embodiment provided by the present invention: a novel crawler self-propelled round baler, including a chassis 1, a mounting seat 2 and a winding head 7, the top of the chassis 1 is installed with a mounting seat 2, and the top of the mounting seat 2 is installed An energy-saving mechanism 3 is provided on one side of the mounting seat 2, a baling chamber 4 is mounted on the top of the mounting seat 2, and a dust-absorbing mechanism 6 is provided on the other side of the top of the mounting seat 2. The dust-absorbing mechanism 6 includes a dust collecting box 601, an air outlet 602, The negative pressure fan 603, the clamping block 604, the filter plate 605, the connecting pipe 606 and the dust suction port 607, the dust collecting box 601 is installed on the other side of the top of the mounting seat 2, and one side of the dust collecting box 601 is provided with an air outlet 602, A negative pressure fan 603 is installed inside ...

Embodiment 2

[0030] Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com