A silent food processor

A food processing machine, silent technology, applied in the field of food processing, can solve the problems such as difficult to clean, easy to stick, etc., to achieve the effect of low noise value, reduction of resonance noise, and offset resonance phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

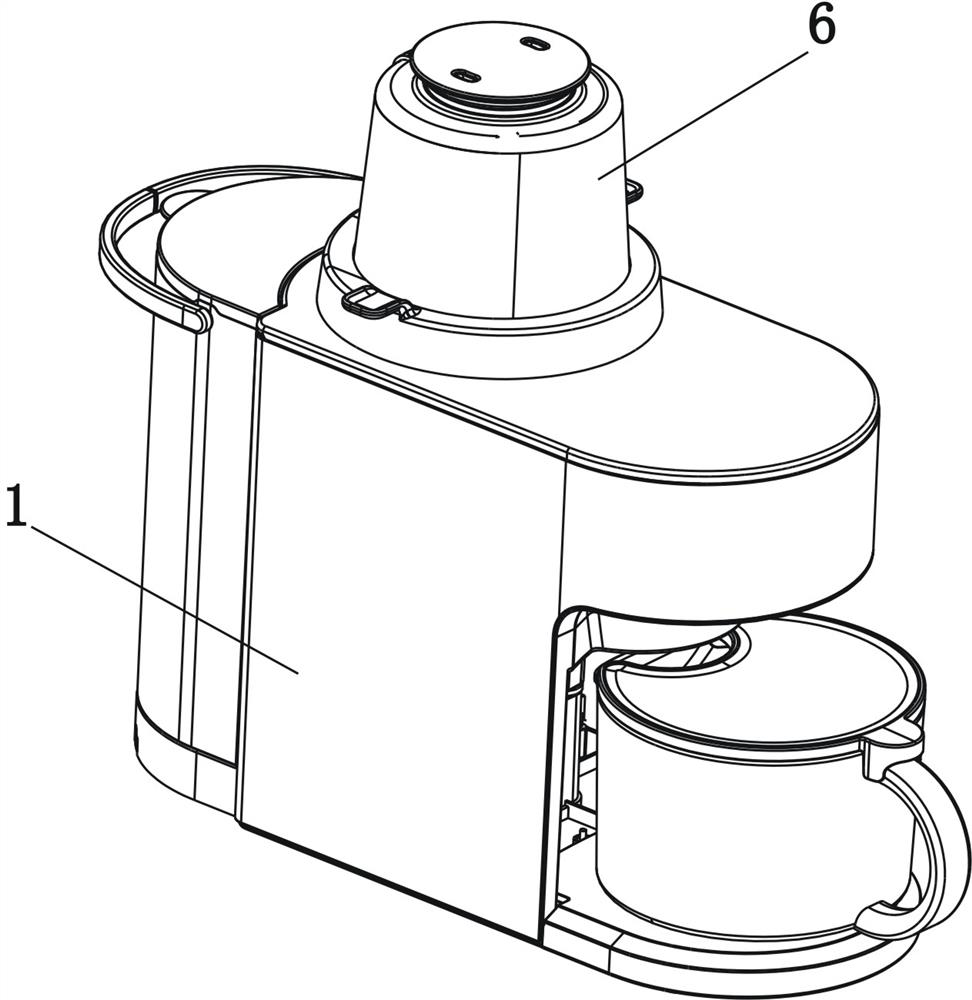

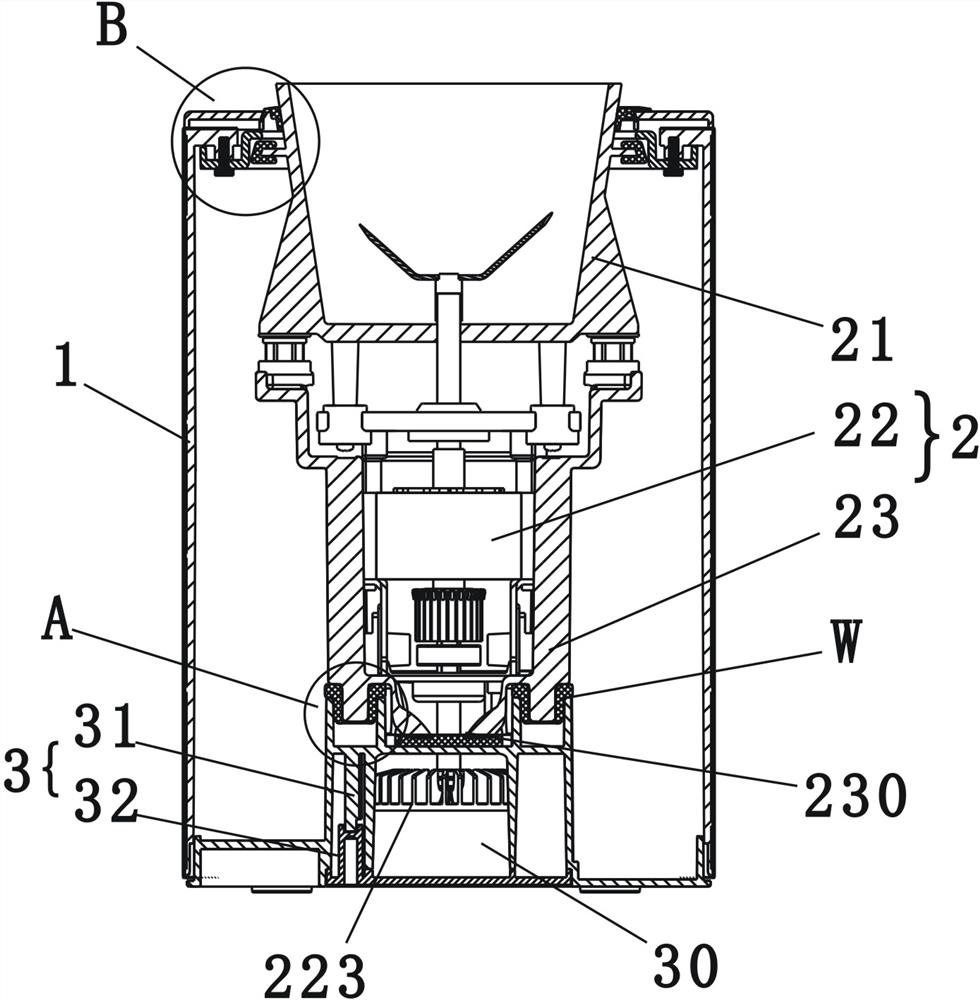

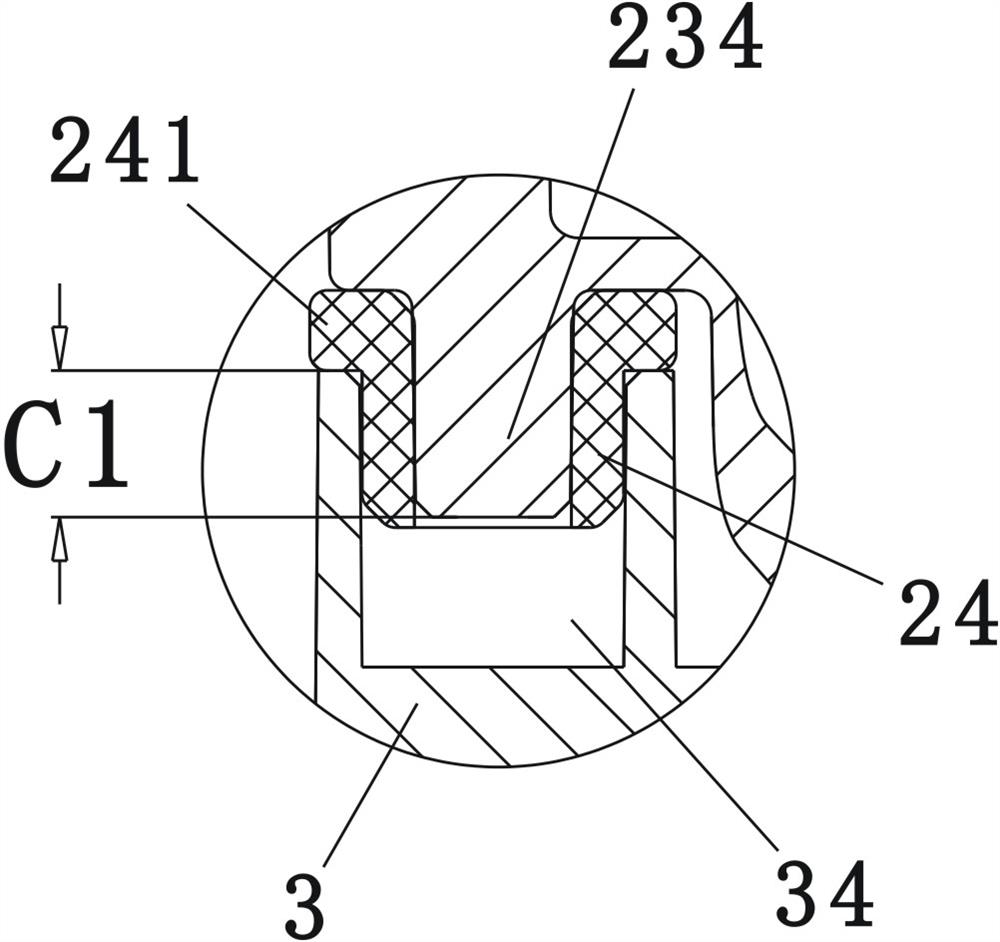

[0039] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, it is a schematic structural diagram of an embodiment of the food processing machine of the present invention. A food processing machine includes a casing 1, a pulverizing container assembly 2 disposed in the casing 1, and a support base 3 for supporting the pulverizing container assembly 2, the supporting base 3 is located at the bottom of the casing 1 and is connected with the casing. 1 is fixed, the pulverizing container assembly 2 includes a pulverizing container 21, a motor 22 integrally connected with the pulverizing container 21, and a connecting bracket 23, the motor 22 is located at the bottom of the pulverizing container 21, and the connecting bracket 23 is located outside the motor 22 , and its upper end is fixedly connected with the crushing container 21, and the lower end extends toward the rear end of the motor 22, and the lower end of the connecting bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com