Leg fracture reduction machine

A leg and frame technology, applied in the field of leg fracture reduction machines, can solve the problems of difficult reduction, angular displacement, high price, etc., and achieve the effects of avoiding secondary injuries, meeting reduction requirements, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

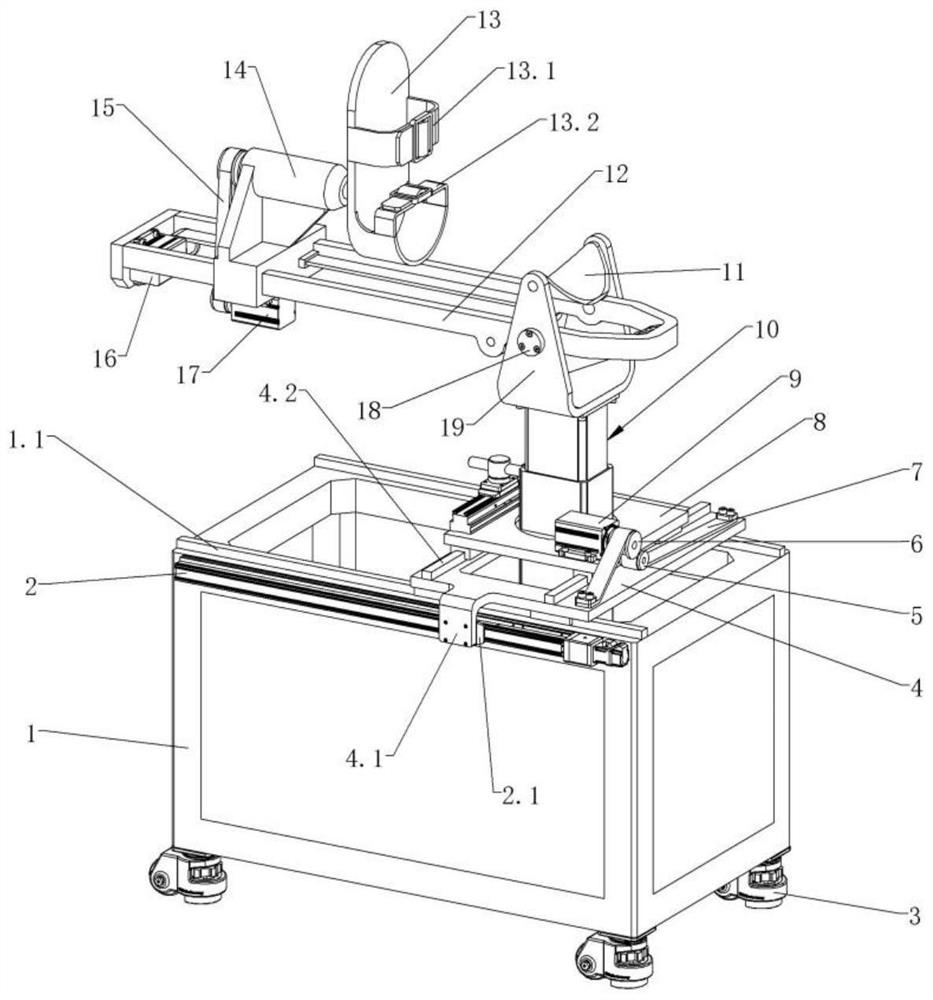

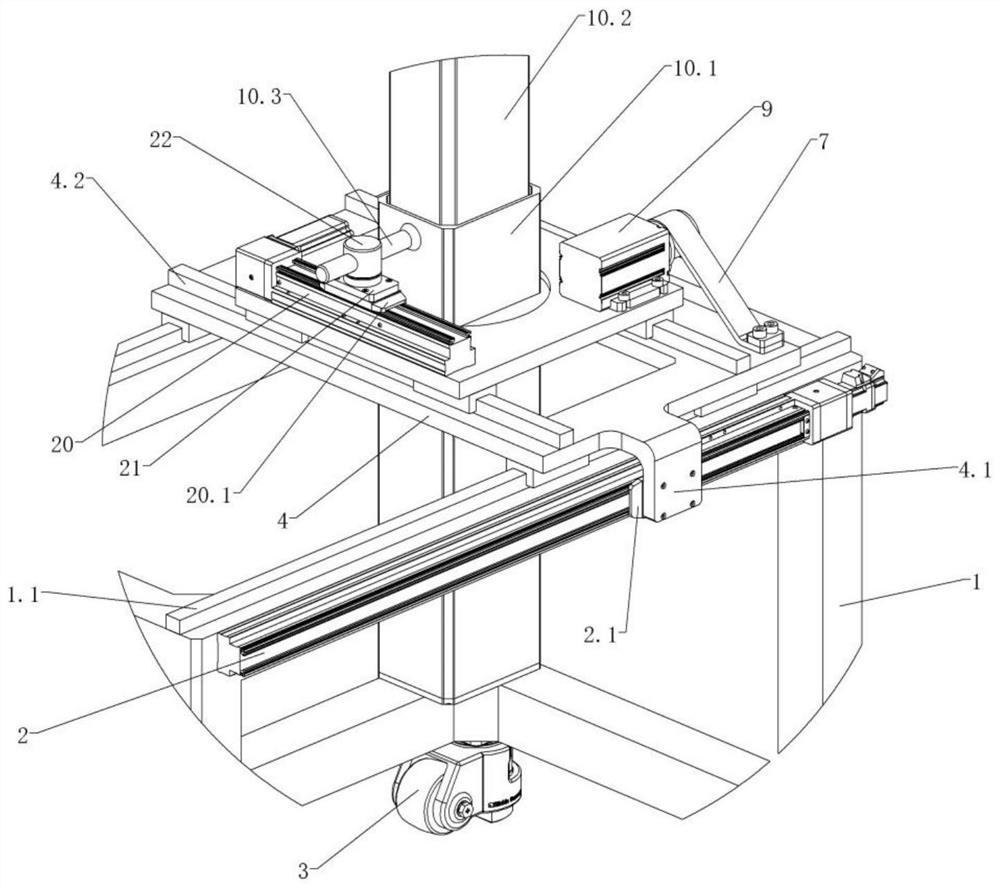

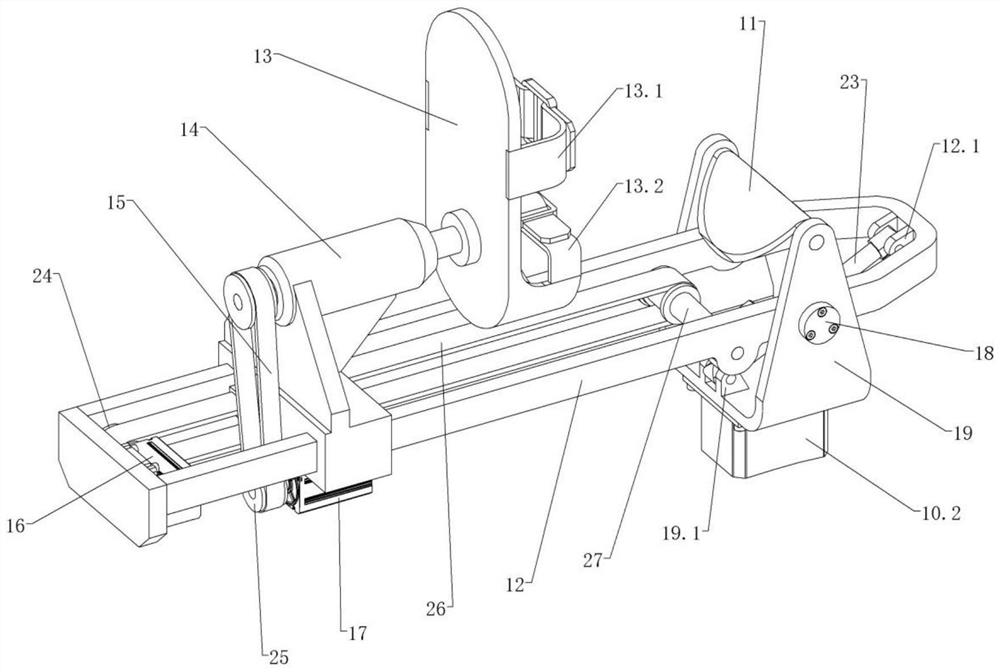

[0022] like figure 1 As shown in the figure, a leg fracture reduction machine includes a frame 1, a first sliding table 2, a Fuma wheel 3, a vertical sliding plate 4, a guide wheel 5, a first driving wheel 6, a first synchronous belt 7, and a horizontal sliding plate 8 , the first motor 9, the lifting column 10, the support plate 11, the vertical guide frame 12, the foot frame 13, the carriage 14, the third timing belt 15, the second motor 16, the third motor 17, the fixed shaft 18, the U-shaped frame 19. The second sliding table 20, the traverse table 21, the dial shaft 22, the electric cylinder 23, the second driving wheel 24, the third driving wheel 25, the second timing belt 26, the first driven wheel 27, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com