Waste oil purifying, cleaning, collecting and adsorbing device

An adsorption device and oil purification technology, which is applied in the direction of grease/oily substance/floating matter removal device, adsorption water/sewage treatment, smoke and dust removal, etc., can solve the problems of waste oil that is difficult to discharge, a large amount of waste oil, etc., and achieve easy purification, Improve cleaning effect, improve the effect of collecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

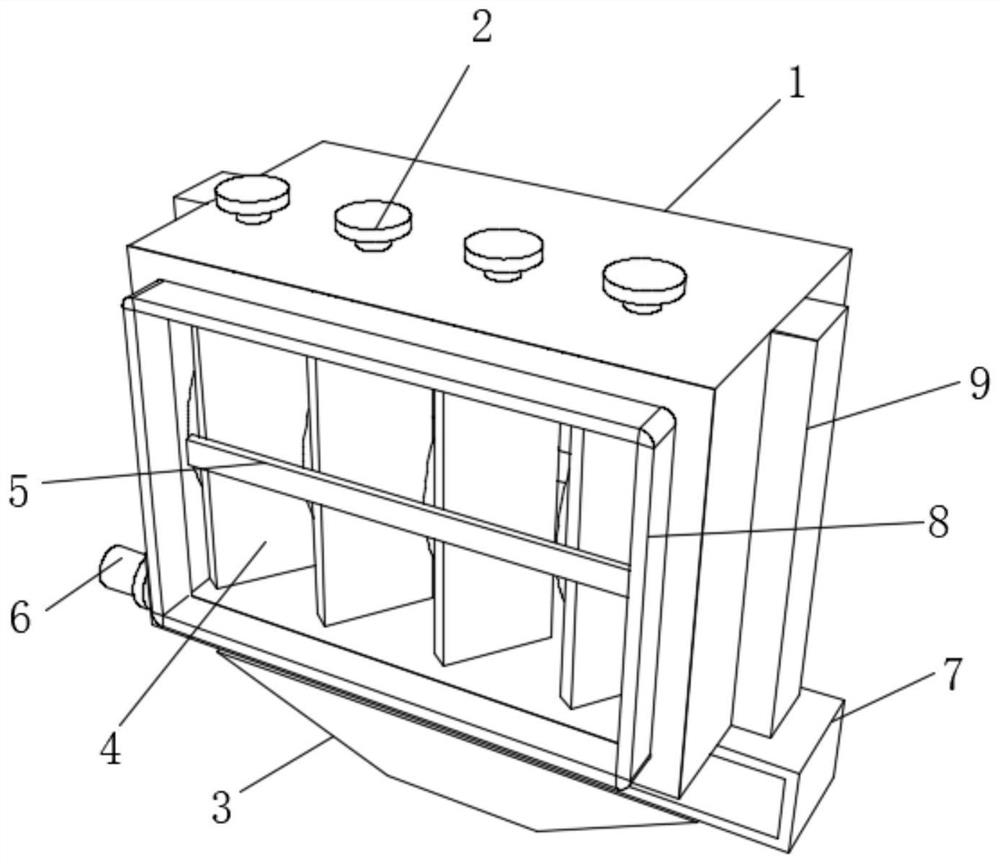

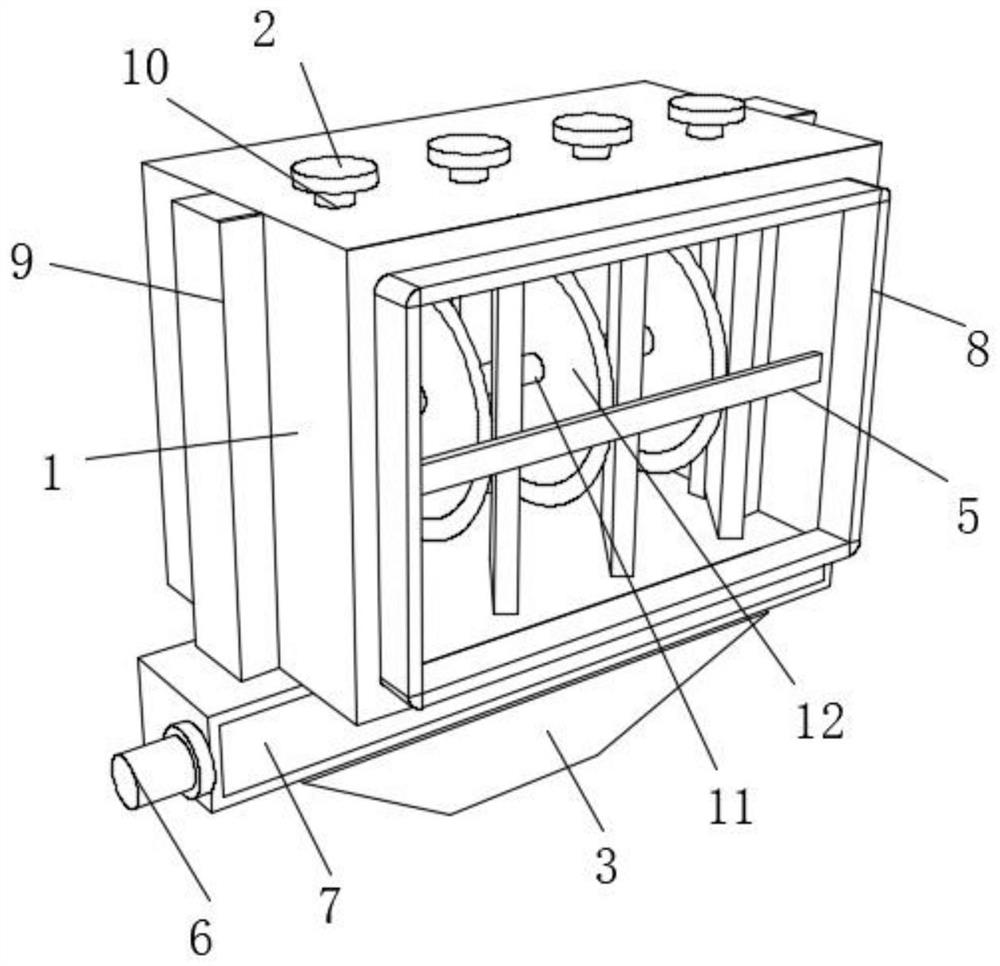

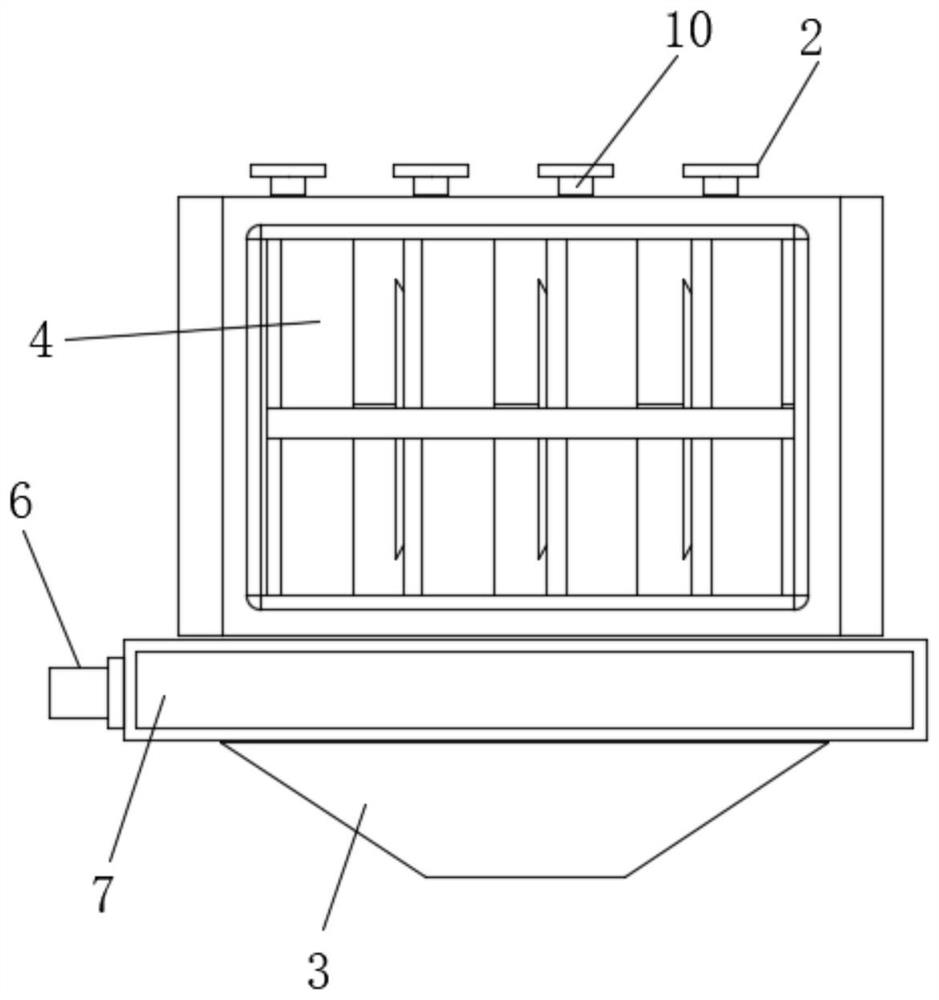

[0031] like Figure 1-8 As shown, the embodiment of the present invention provides a waste oil purification, cleaning, collection and adsorption device, including a casing 1, the bottom of the casing 1 is fixedly connected to an organic casing 7, one side of the casing 7 is fixedly connected to a motor 6, and the output end of the motor 6 A transmission shaft 18 is fixedly connected, one end of the transmission shaft 18 is rotatably connected to one end of the casing 7, the outer ends of the transmission shaft 18 are fixedly connected with a first bevel gear 17, and the outer sides of the two first bevel gears 17 are threaded A second bevel gear 21 is connected, the middle of the two second bevel gears 21 is fixedly connected with a threaded rod 14, the outer sides of the two threaded rods 14 are threadedly connected with a threaded moving block 15, and one side of the threaded moving block 15 is slidably connected On the inner side of the guide box 9, the two ends of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com