Method for preparing carbon fiber part by adopting hot pressing method

A carbon fiber and parts technology, which is applied in the field of carbon fiber parts prepared by hot pressing, can solve the problems of destroying the texture of carbon fiber parts, poor customer sensory experience, affecting product prices, etc., and achieves the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

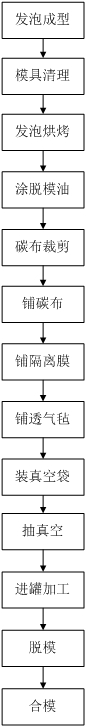

[0020] see figure 1 , the embodiment of the present invention provides a method for preparing carbon fiber parts by hot pressing, and the carbon fiber parts are specifically pipe fittings, and the method includes:

(1) Foaming molding: a preformed mold is obtained by foaming molding of self-foaming materials.

[0021] (2) Foaming and baking: bake the preformed mold at 65° C. for 80 minutes and apply mold release oil.

[0022] (3) Cutting of carbon cloth: The carbon cloth pre-impregnated with resin is cut according to the design size. The carbon cloth is 6K carbon cloth and its resin content is 40%, and the resin is epoxy medium temperature resin.

[0023] (4) Lay-up: Lay the carbon cloth obtained in step (3) on the pre-forming mold while it is still hot, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com