Damp-proof breathable composite non-woven fabric preparation device

A technology for preparing devices and non-woven fabrics, which is applied to heating devices, non-woven fabrics, textiles, and papermaking, and can solve the problems that the base does not have the function of collecting water, affecting the normal preparation of moisture-proof and breathable non-woven fabrics, and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

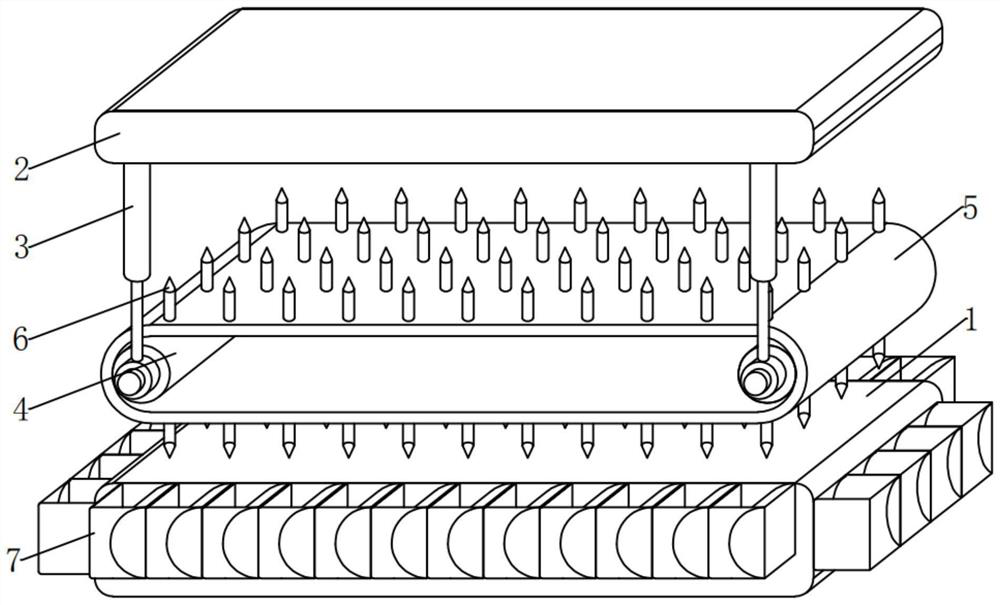

[0050] see Figure 1-2 , in the embodiment of the present invention, a moisture-proof and breathable composite non-woven fabric preparation device, comprising:

[0051] The base 1, the top plate 2 is arranged at the position directly above the base 1, and the left and right ends of the bottom side of the outer front of the top plate 2 are fixedly installed with telescopic rods 3 in the vertical direction. Both are installed with support rollers 4, the bottom end tail of the telescopic rod 3 is fixedly installed at the front, top, middle end of the support rollers 4, and a processing belt 5 is wrapped around the outer surfaces of the left and right support rollers 4. The processing belt The outer surfaces of the top and bottom sides of the two sides of the top and bottom are equidistantly arranged and fixedly installed with a number of thorns 6;

[0052] The water collecting assembly 7, the outer surfaces of the front, rear, left, right, and four sides of the base 1 are adjace...

Embodiment 2

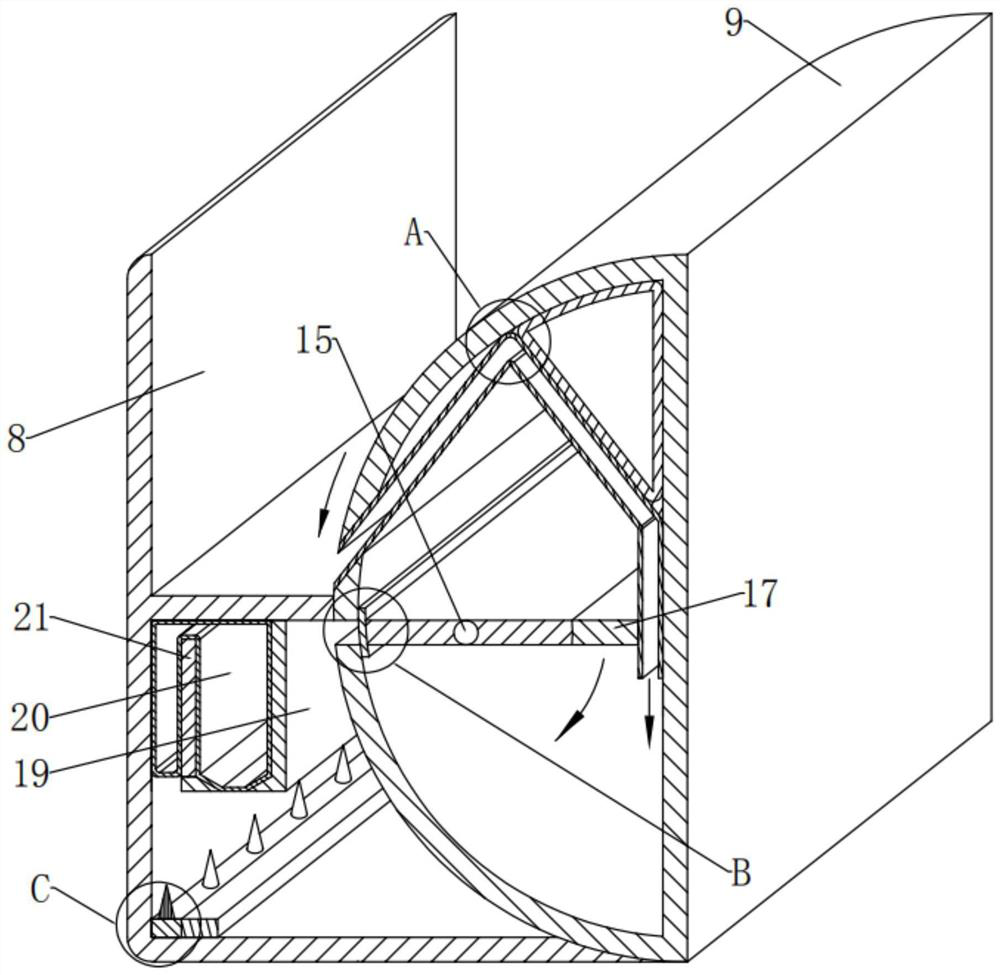

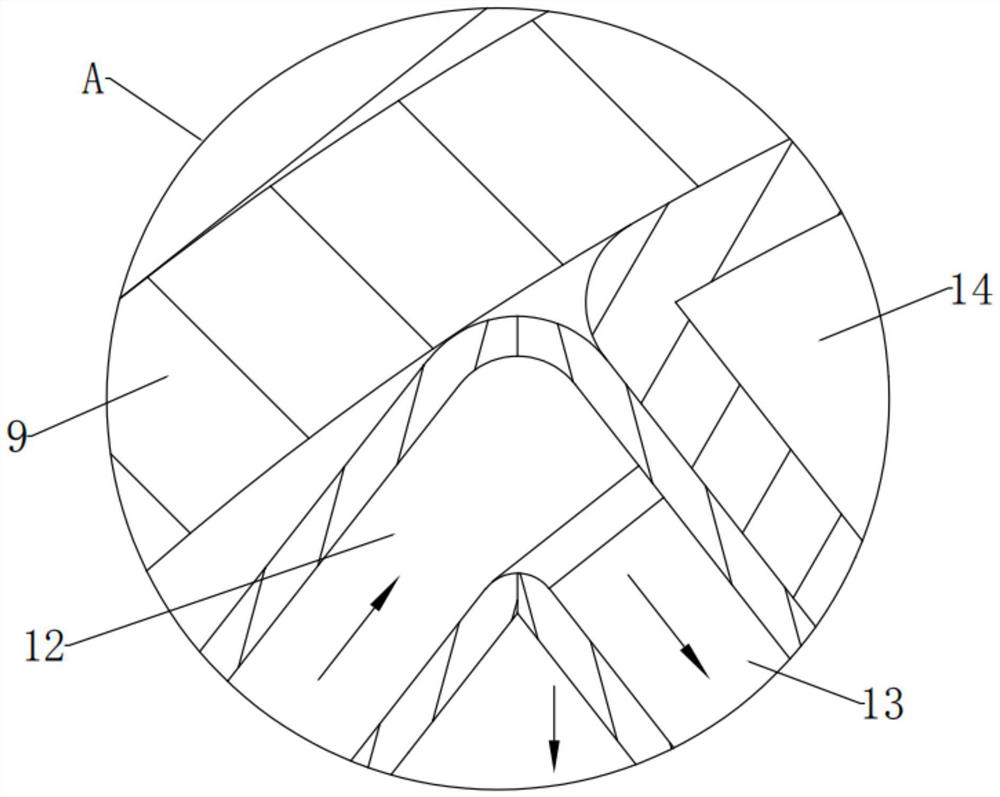

[0064] see Figure 2-4 and Figure 6-7 , the difference between the embodiment of the present invention and the embodiment 1 is that the water guide assembly 10 includes:

[0065] The water diversion groove 12, the water diversion groove 12 is fixed and installed obliquely at the inlet position of the right shell 9, and the appearance of the water diversion groove 12 is in the shape of a short parallel straight plate with hollow interior, end-to-end penetration, left low and right high on a longitudinal section. The included angle of the horizontal plane is 52°, the inlet at the bottom of the left end of the gutter 12 faces the outer surface of the top side of the horizontal plate of the left shell 8 and there is a distance between the two, and the outlet at the top of the right end of the gutter 12 is located at the upper end of the left inner wall of the right shell 9 Positioned and facing the upper end surface of the right inner wall of the right shell 9, the water diversion...

Embodiment 3

[0083] see figure 2 and Figure 5-7 , the difference between the embodiment of the present invention and the embodiment 1 is that the water absorbing component 11 includes:

[0084] The fixing plate 19, the right end position of the bottom side outer surface of the horizontal plate of the left shell 8 is fixedly installed with the fixing plate 19, the appearance of the fixing plate 19 is in the shape of an inverse letter "L" on a longitudinal section, and the middle position of the bottom end of the fixing plate 19 is There is an outlet running through up and down, and the appearance of the outlet is in the shape of an inverted trapezoid that is inclined left and right on a longitudinal section, with a wide top and a narrow bottom. There is a distance between the outer surface of the right top end of the fixing plate 19 and the inlet of the right shell 9;

[0085] The fixing plate 19 here is in the shape of an inverse letter "L" on a longitudinal section, so as to support a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com