Large-area complex curved surface synchronous impact loading method

A complex curved surface, synchronous impact technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult synchronous detonation, ignoring explosives, and high requirements on the synchronization of the detonation system, to achieve continuous adjustable gradient changes, and to realize explosive charging Quantity, the effect of ensuring time synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

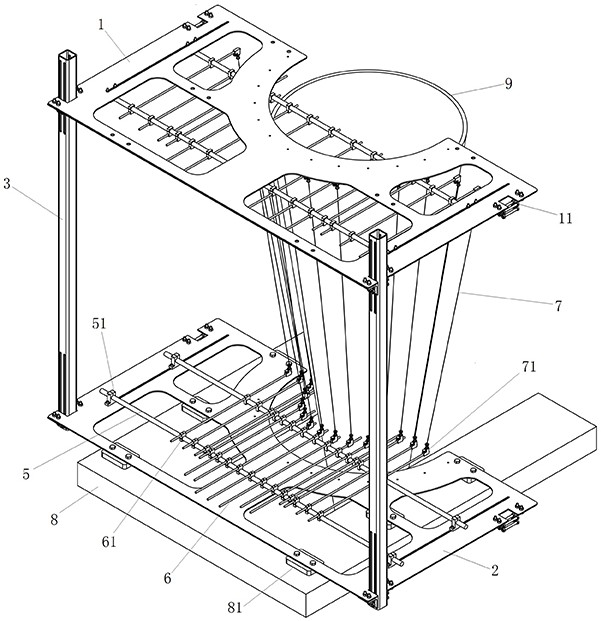

[0014] The synchronous impact loading method for large-area complex curved surfaces in this embodiment includes the following steps:

The photosensitive explosive powder is uniformly mixed in the liquid dispersant according to the mixing ratio of the powder to the liquid dispersant after the static deposition of the mixed solution is 1:10. In this embodiment, the liquid dispersant is acetone.

[0015] The load planned to be loaded on the surface of the target object is converted into the thickness of the photosensitive explosive charge according to the properties of the photosensitive explosive and the concentration of the photosensitive explosive powder in the liquid dispersant; in this embodiment, the photosensitive explosive powder with an areal density of 10 mg / cm^2 corresponds to the specific impulse is 4.73Pa•s, and the corresponding spray thickness is 0.44mm. If a specific impulse of 14.19 needs to be loaded, the corresponding spray thickness should be 0.88mm.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com