Separated potting waterproof fan

A waterproof fan, separate technology, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of damaged objects to be charged, easily damaged electronic parts, difficult to repeat production and manufacturing, etc., to improve the three. Anti-resistance, reasonable structure, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below with reference to the accompanying drawings and embodiments.

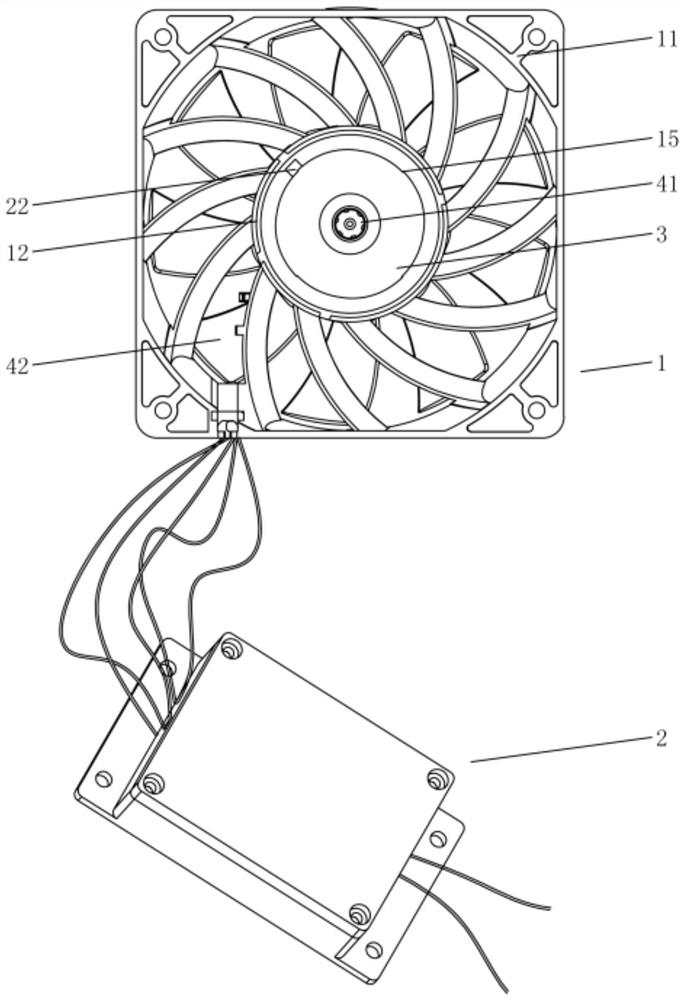

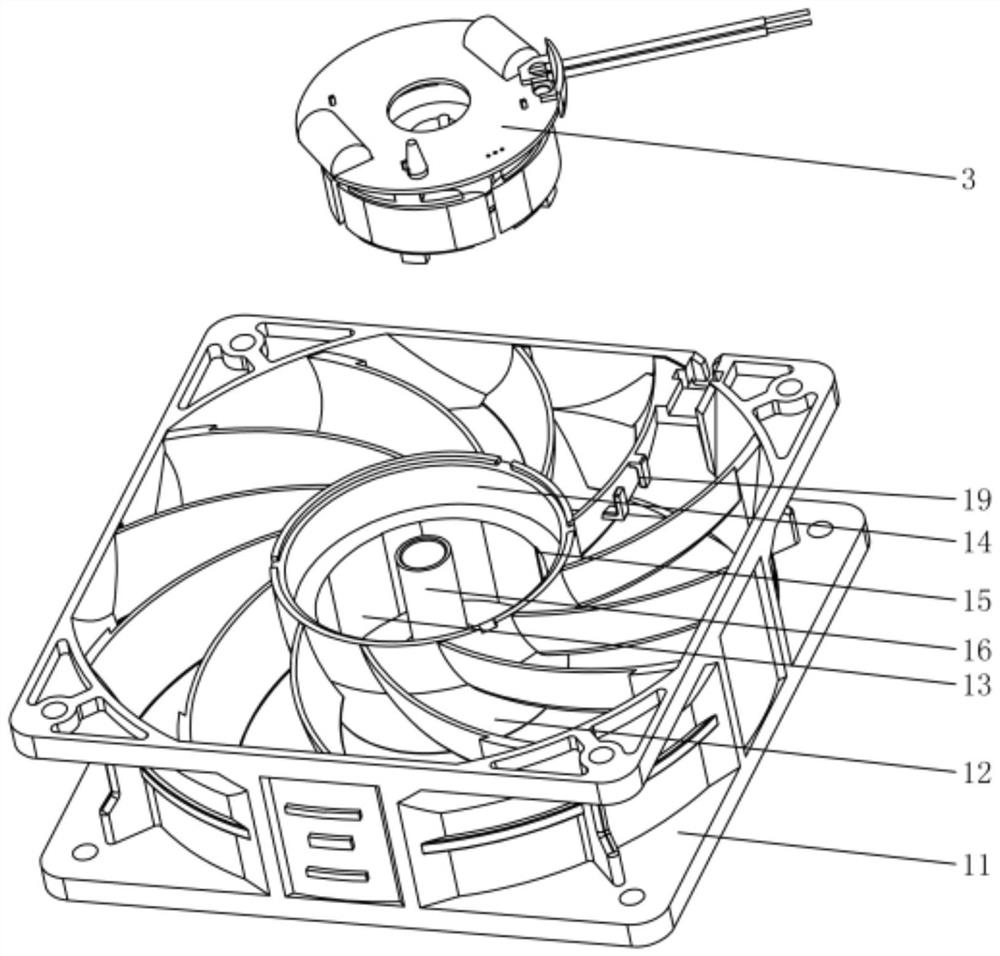

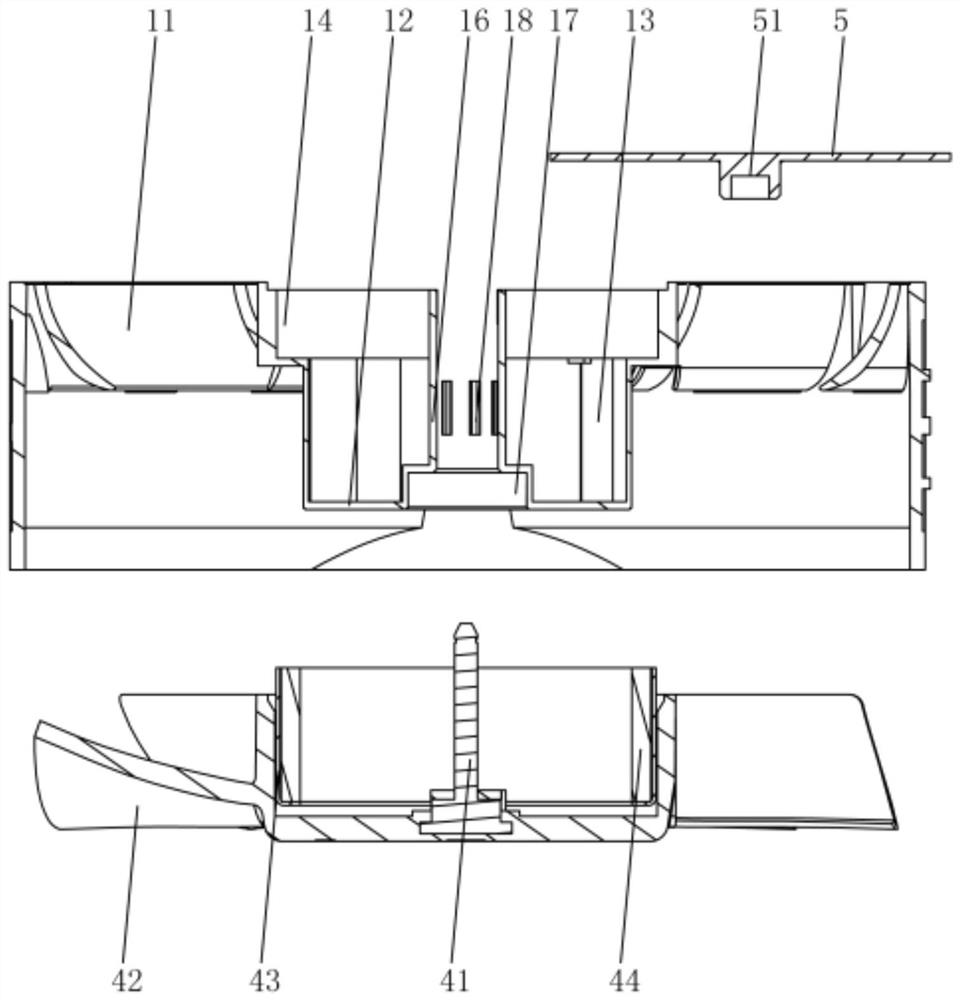

[0021] like Figure 1-4 As shown, a separate potting waterproof fan according to the present invention includes a fan main body 1 and a control box 2. The fan main body 1 includes a fan frame body 11, a stator assembly 3 and a fan assembly 4. A potting body 12 is provided in the center, and the fan assembly 4 is rotatably connected to the potting body 12; the potting body 12 is a hollow structure with an open upper end, and the lower inner cavity of the potting body 12 is an assembly cavity 13, and the potting body 12 The upper inner cavity is the filling cavity 14; the stator assembly 3 passes through the assembly cavity 13 and is connected with the potting body 12, and the filling cavity 14 is filled with sealing filler; the control box 2 is provided with a PCB circuit board 21. The wires on the stator assembly 3 pass through the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com