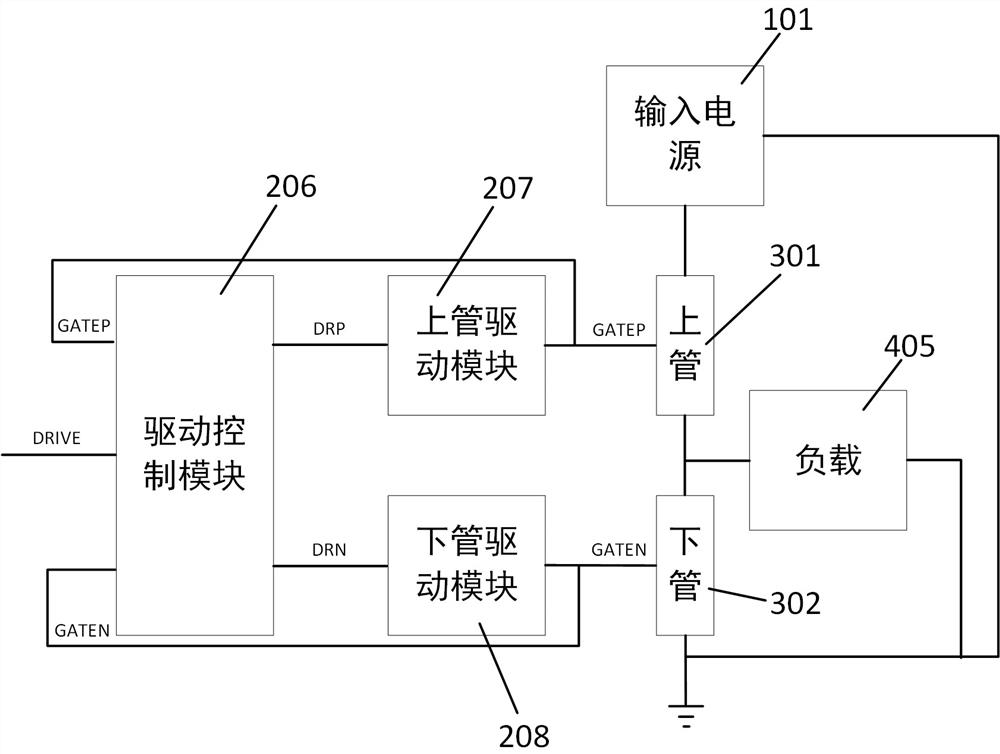

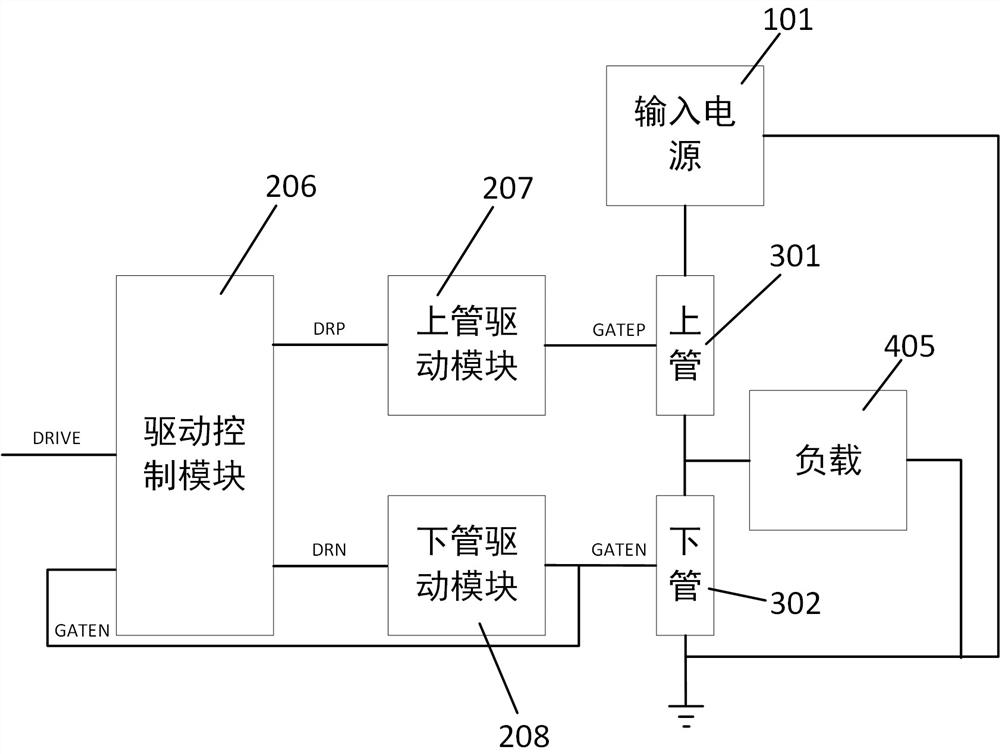

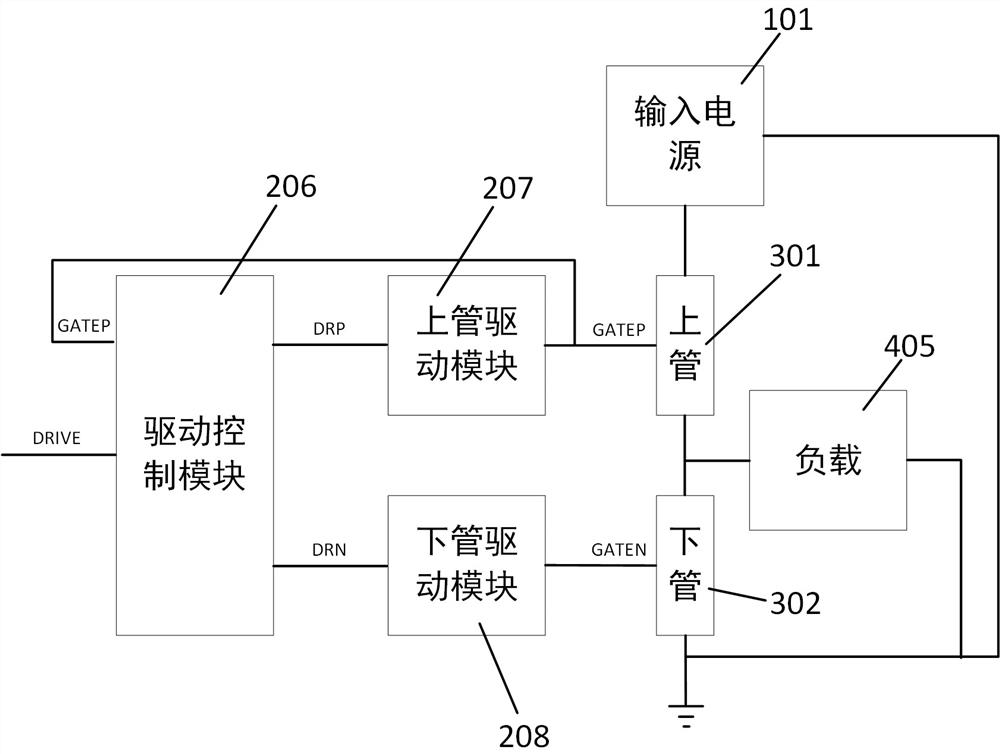

Drive control module and synchronous rectifier circuit

A technology of drive control and synchronous rectification, which is applied in control/regulation systems, electrical components, and regulation of electrical variables, etc. It can solve the problems of dead time affecting conversion efficiency and poor compatibility, achieve short switching intervals, and improve compatibility , Improve the effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make the objects, advantages and features of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that the accompanying drawings are all in a very simplified form and are not drawn to scale, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention. Furthermore, the structures shown in the drawings are often part of the actual structure. In particular, each drawing needs to show different emphases, and sometimes different scales are used.

[0076] As used herein, the singular forms "a," "an," and "the" include plural referents, the term "or" is generally employed in its sense including "and / or", and the term "a number" It is usually used in the sense including "at least one", the term "at least two" is usually used in the sense including "two or more", in addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com