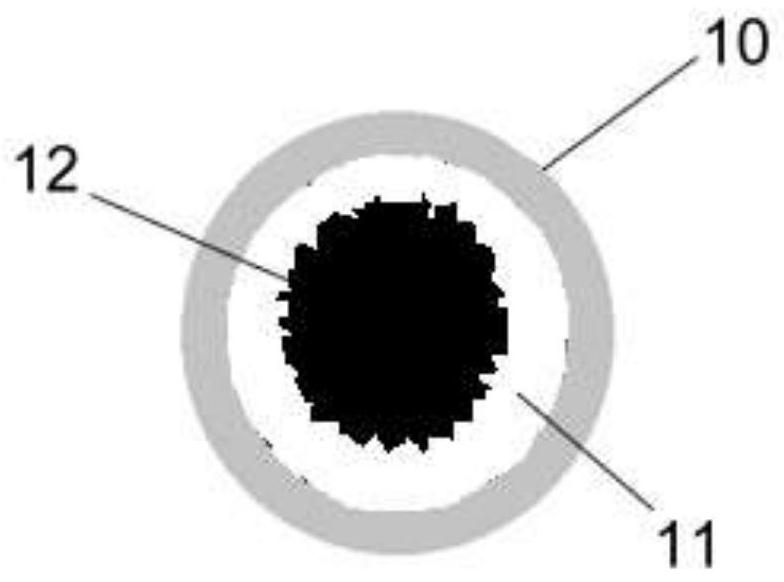

Planting material particle

A planting material and particle technology, which is applied in the field of planting material particles for plant cultivation, can solve the problems of small pores that cannot be filled with soft planting material core materials, pores that are not connected to each other, and limited water absorption and water retention. Reduce the frequency of watering and avoid the effect of boring and rotten roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] 3. Preparation of growing medium granules:

[0088] Preparation of the kernel: select a natural animal and plant material or ready-made commodity that meets the requirements to process the kernel, the processing method may be, for example, the drip pill method, the pellet machine shear granulation method or other similar methods known to the prior art, the flexible material is made into a cavity suitable for placing (or pre-positioned) the hard growing medium shell in the core.

[0089] Preparation of the shell: directly using the natural plant shell or core shell that meets the requirements, animal shell, or the selection of ready-made goods for further processing, the processing method can be molding method, inflation method, foaming method, baking method, or two or more methods of comprehensive application, can also be made of other similar molding processes known in the prior art.

[0090] Integral molding preparation of growing medium particles:

Embodiment 1

[0102] Example 1, the preparation of growing medium particles

[0103] 1. Preparation of chamber filler or flexible soft growing medium core

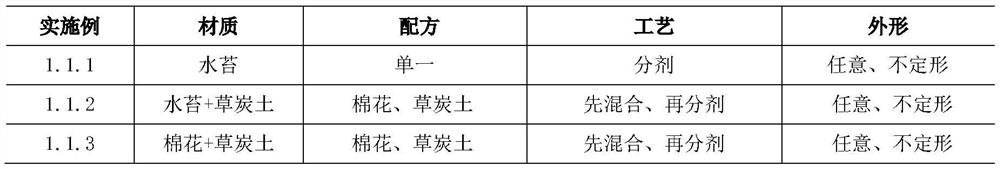

[0104] 1.1. Chamber filler or flexible soft growing medium core prepared from natural materials:

[0105]

[0106] Note: Since the chamber filler or flexible soft growing medium core has the common characteristics of not affecting the curative properties of shell hard planting, harmless to plant roots, can absorb and retain water during the planting period but is not dissolved or dissolved by water, elastic or flexible, therefore, in the natural material, water moss, grass charcoal soil, cotton as the representative of the core embodiment of this type.

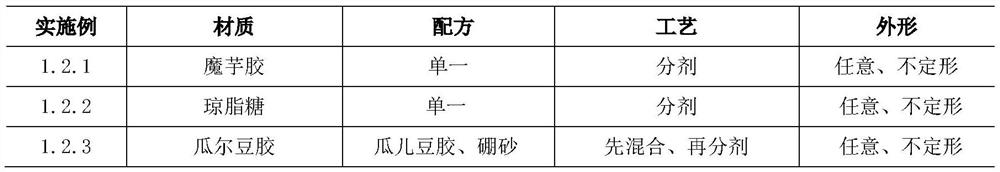

[0107] 1.2, natural materials reprocessed materials prepared of chamber filler or flexible soft growing medium core:

[0108]

[0109] Note: Since the chamber filler or flexible soft growing medium kernel has the common characteristics of not affecting the shell hard planting cooking pe...

Embodiment 2

[0141] Example 2, the comprehensive application of growing medium particles

[0142] 2.1. Compounding of chamber filler or soft growing medium core of chamber type growing medium particles

[0143] Forming a chamber type growing medium particles of the present invention is filled or soft grown medium core, both may be used only with a water-absorbent material, may further add other materials to increase fertility, and / or improve water absorption compound composition.

[0144]

[0145] Note: Since the chamber filler or soft growing medium core material, the same as the further added fertilizer, as long as it can be filled into the granular growing media chamber, and the variety that needs to be added is not of much relevance, therefore, can only be water moss, saprophyll soil, polymer water-absorbing resin as representative of the compound with slow-release fertilizer particles as such embodiments.

[0146] 2.2, chamber type growing medium particles of hard shell compounding

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com