Clamping device for automatic automobile production line

An automatic production line, clamping device technology, applied in the direction of workpiece clamping device, cleaning method using gas flow, cleaning method and utensils, which can solve the problem that the clamping mechanism cannot be adjusted, the surface of the part is worn, and the auto parts that cannot be clamped Protection and other issues to achieve the effect of increasing the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

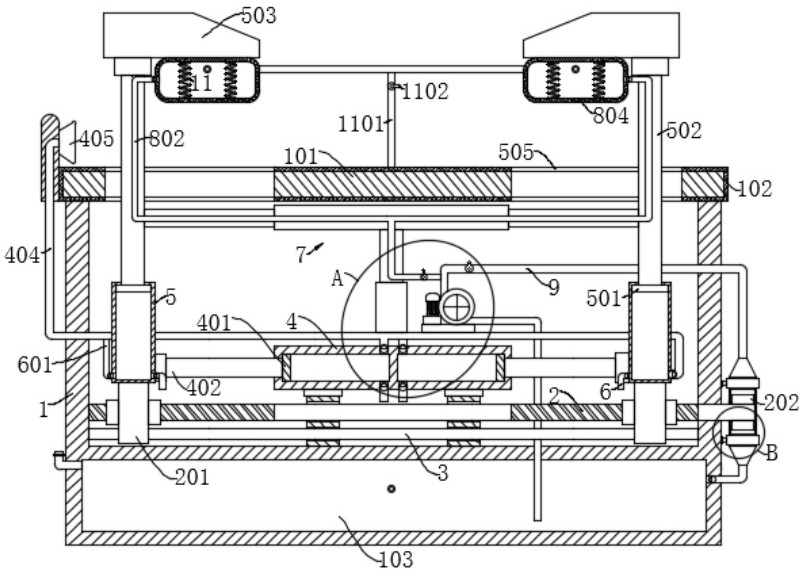

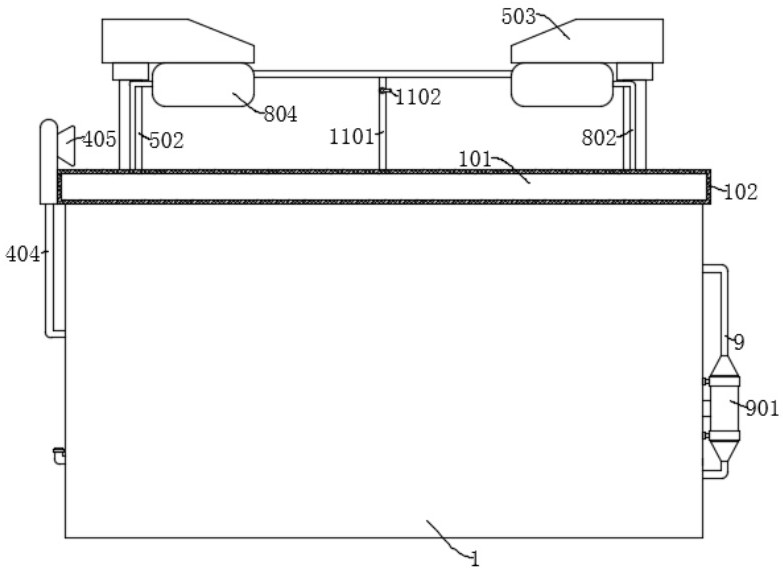

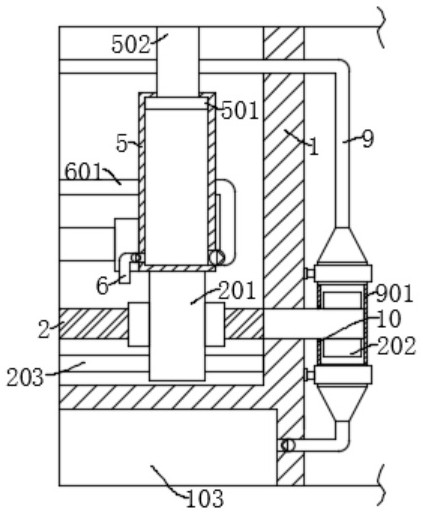

[0026] Example 1: Reference Figure 1-6, for the clamping device of the automotive automated production line, including housing 1, housing 1 top fixed connection to the support plate 101, housing 1 is provided with a water storage chamber 103, further comprising: symmetrically set with two sets of connectors 201, two sets of connectors 201 are set in the housing 1; Sleeve two 5, fixed mounted on two sets of connecting seats 201; Sleeve one 4, fixed mounted on the inner wall of the bottom of housing 1; Piston disc one 401, sliding connection in sleeve one 4, and piston disk one 401 and sleeve two 5 outer wall through the guide rod one 402 fixed connection; Nozzle 405, fixed to the support plate 101; Catheter one 403, one end of which is connected to the sleeve one 4; Catheter II 404, one end of which is connected to the sleeve one 4, the other end is connected to the nozzle 405; Piston disc II 501, sliding connection within sleeve II 5; Pipe one 6, connected to the sleeve two 5, sle...

Embodiment 2

[0032] Example 2: Reference Figure 1 、 Figure 3 、 Figure 4 、 Figure 5 and Figure 6 , the clamping device for the automotive automated production line, substantially the same as Example 1, further is the drive component comprises a reciprocating screw 2, the reciprocating screw 2 rotation is connected to the inner wall of the housing 1, and the reciprocating screw 2 runs through the outer wall of one end of the supercharged tube 901 is fixedly connected to the impeller 202, the connector 201 is connected to the reciprocating screw 2 thread connection, the housing 1 is provided for the limiting limit of the connecting seat 201, the connecting seat 201 slides connected to the limit component.

[0033] Limiting components include a guide support rod 3, the guide support rod 3 is fixedly connected to the inner wall of the housing 1, the connecting seat 201 slides connected to the guide support rod 3.

[0034] The support plate 101 is opened with a chute 505, the connecting rod 502 slid...

Embodiment 3

[0038] Example 3: Reference Figure 1 、 Figure 3 and Figure 6 , the clamping device for the automotive automated production line, and Example 1 is basically the same, further, the pressurized tube 901 is provided with a sealing ring 10, the sealing ring 10 is fitted to the outer wall of the reciprocating screw 2; When the water flow impact impeller 202 through the booster pipe 901 drives the reciprocating screw 2 to rotate, the outer wall of the sealing ring 10 reciprocating screw 2 provided on the pressurized pipe 901 is attached, which can increase the sealing of the pressurized pipe 901, thereby effectively preventing the leakage of water through the pressurized pipe 901.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com