High-efficiency plastic sheet machine

A sheet machine and high-efficiency technology, applied in the field of high-efficiency plastic sheet machines, can solve the problems of difficult plastic sheet processing quality assurance, plastic raw materials that are prone to bubbles, damage or fracture, etc., to maintain uniform flow and distribution, avoiding component damage, and avoiding the effect of precipitation and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

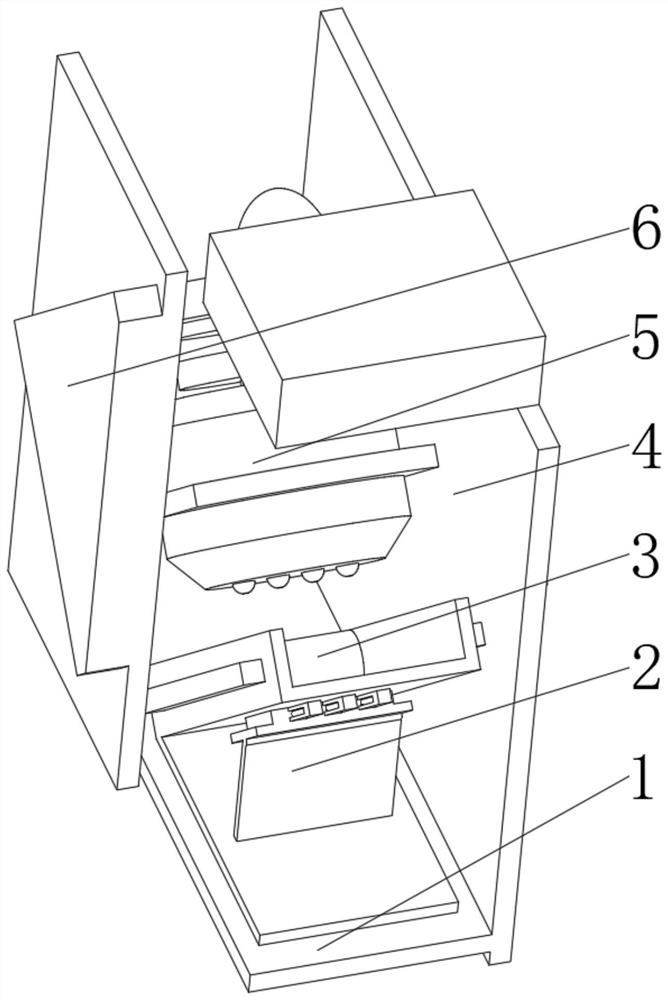

[0037] see Figure 1-5 , the present invention provides a technical solution: a high-efficiency plastic sheet machine, which specifically includes:

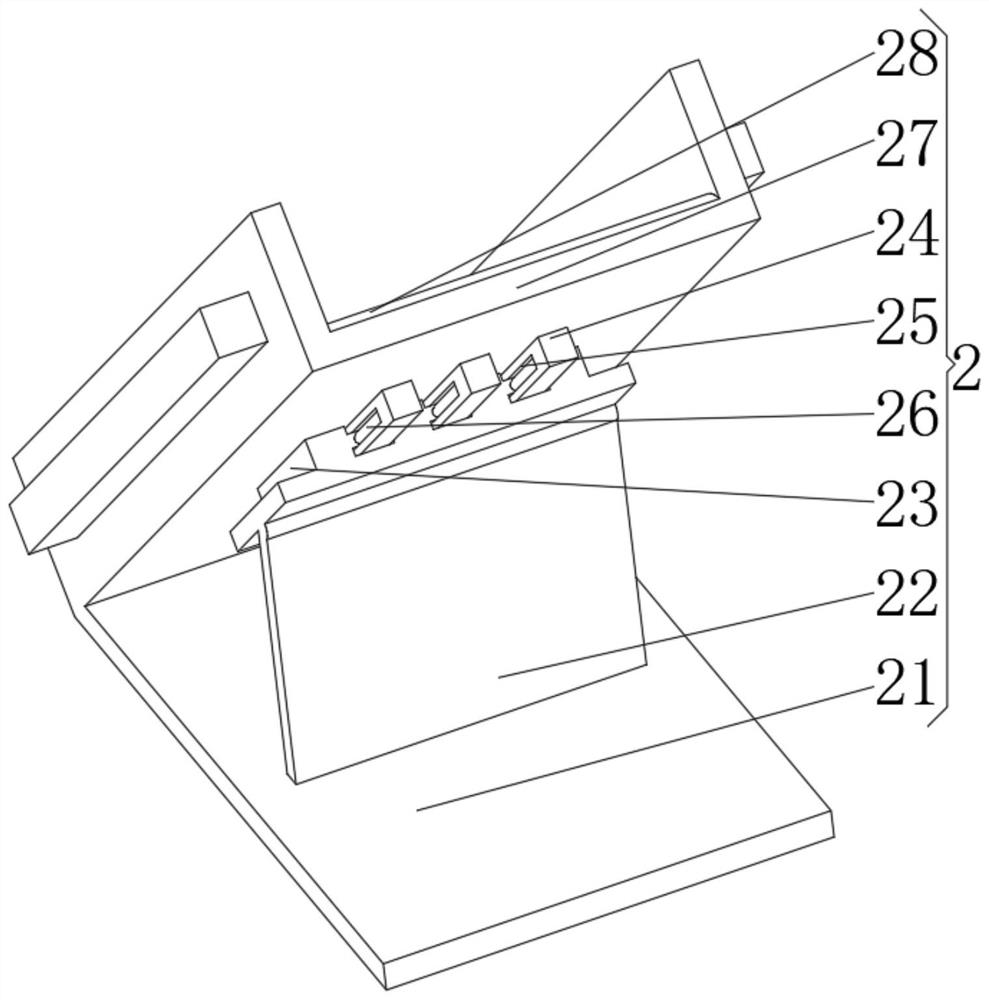

[0038] Bottom separator 1, the bottom separator 1 has a slat main body, and a sheet material device 2 installed in the middle position of the top of the slat main body, and a sheet material roller 3 installed on the top of the sheet material device 2 close to the side of the slat main body, Through the setting of the sheet roller 3, the sheet thickness of the plastic raw material is limited by the sheet roller 3, so as to realize the uniform operation of the sheet specifications, and the rotation direction of the sheet roller 3 is opposite to the flow direction of the plastic raw material. The air inside is exhausted to avoid the existence of air bubbles in the plastic sheet that affects the processing quality, and the component racks 4 installed on the outer walls of both sides of the slat main body are installed on the side of ...

Embodiment 2

[0052] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a high-efficiency plastic sheet machine, comprising the following steps:

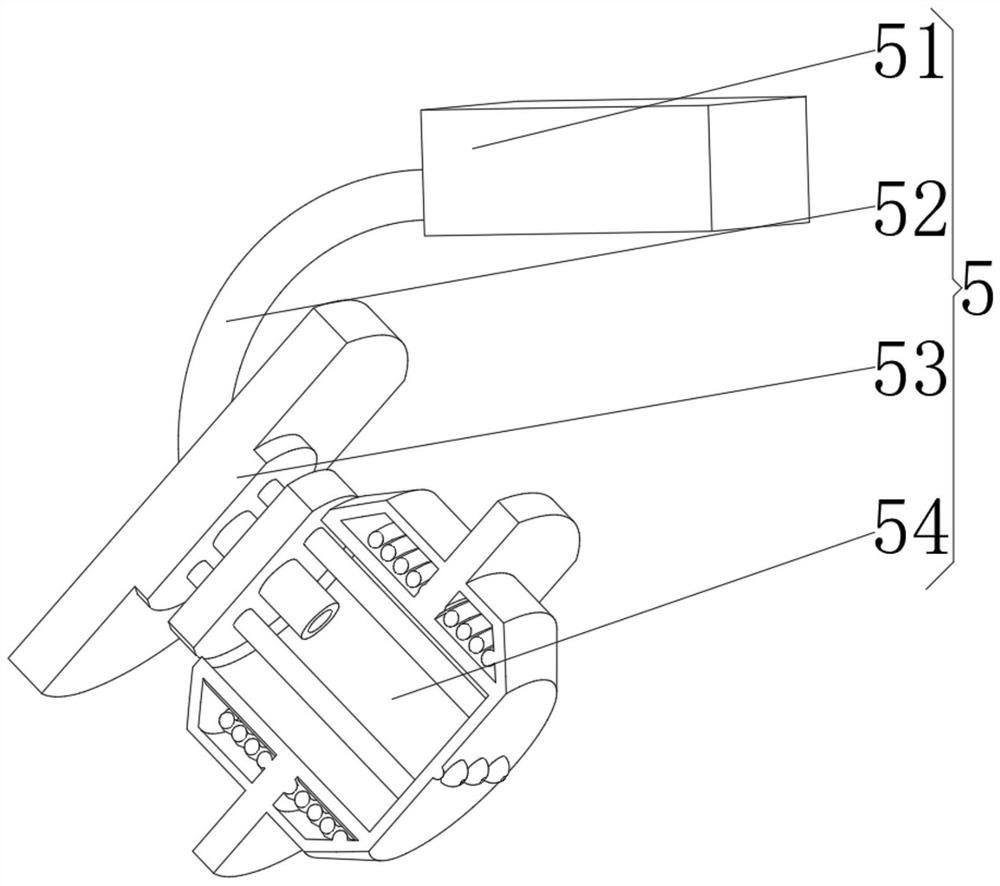

[0053] Step 1: start the feeding pump 51 in the feeding device 5, and transport the plastic raw material to the storage cylinder 541 of the feeding device 54 through the conveying pipe 52;

[0054] Step 2: The weight of the weight plate 535 in the extrusion device 53 is used to make the weight plate 535 fall, and the weight plate 535 slides down along the guide post 534;

[0055] Step 3: The weight plate 535 enters the storage cylinder 541 of the storage device 54, and the helical groove on the inner surface of the storage cylinder 541 is used to guide the weight plate 535, so that the weight plate 535 rotates spirally on the inner surface of the storage cylinder 541;

[0056] Step 4: The rotation of the weight plate 535 drives the guide column 534 and the rotating disk plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com