Chain stopper for scraper conveyor

A scraper conveyor and vertical plate technology is applied in the field of chain blockers for scraper conveyors, which can solve the problems of many parts of the chain blocker, differences in the structure of chain blockers, and inability to achieve interchangeability, etc., and achieves reliable use. , easy to handle, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the technical solutions in the embodiments of the present invention completely and clearly with reference to the accompanying drawings in the embodiments of the present invention. The described embodiments are only a part of the embodiments of the present invention, but not all of them.

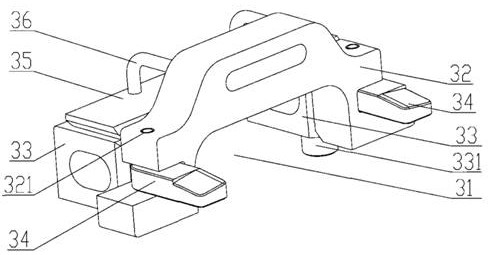

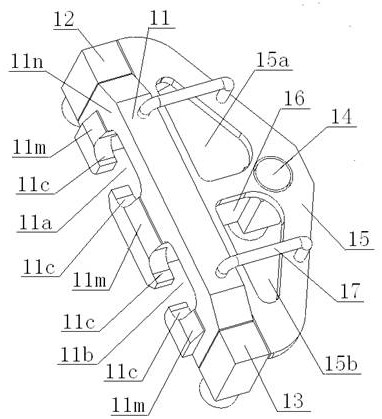

[0020] like image 3 As shown, the present invention provides a chain stopper for scraper conveyor, which is composed of a front vertical plate 11, a left positioning pin 12, a right positioning pin 13, a rear positioning pin 14, a top plate 15, a support plate 16, a handle 17, etc. Welding to form a whole, the lower end of the front vertical plate 11 of the chain blocker is provided with grooves 11a and 11b arranged symmetrically on the left and right sides, the bottom of the groove has a limit hook 11c, and the outer facade 11n of the front vertical plate 11 of the chain blocker has The inclined plane boss 11m, the trapezoidal weight-reducing holes 15a and 15b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com