Oxygen supply device and method in deodorant fermentation process

A fermentation process and oxygen supply device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem that the oxygen supply effect cannot be further improved, and achieve good oxygen supply , increase biological activity and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

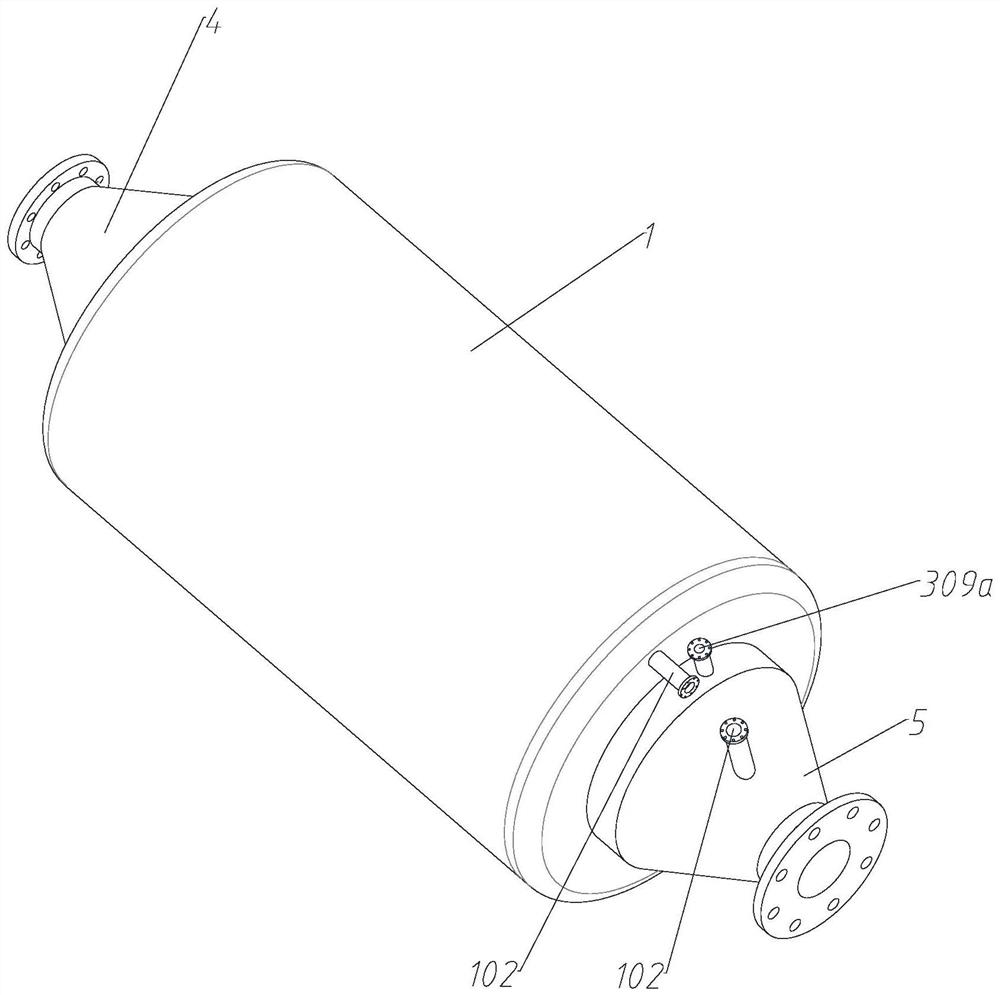

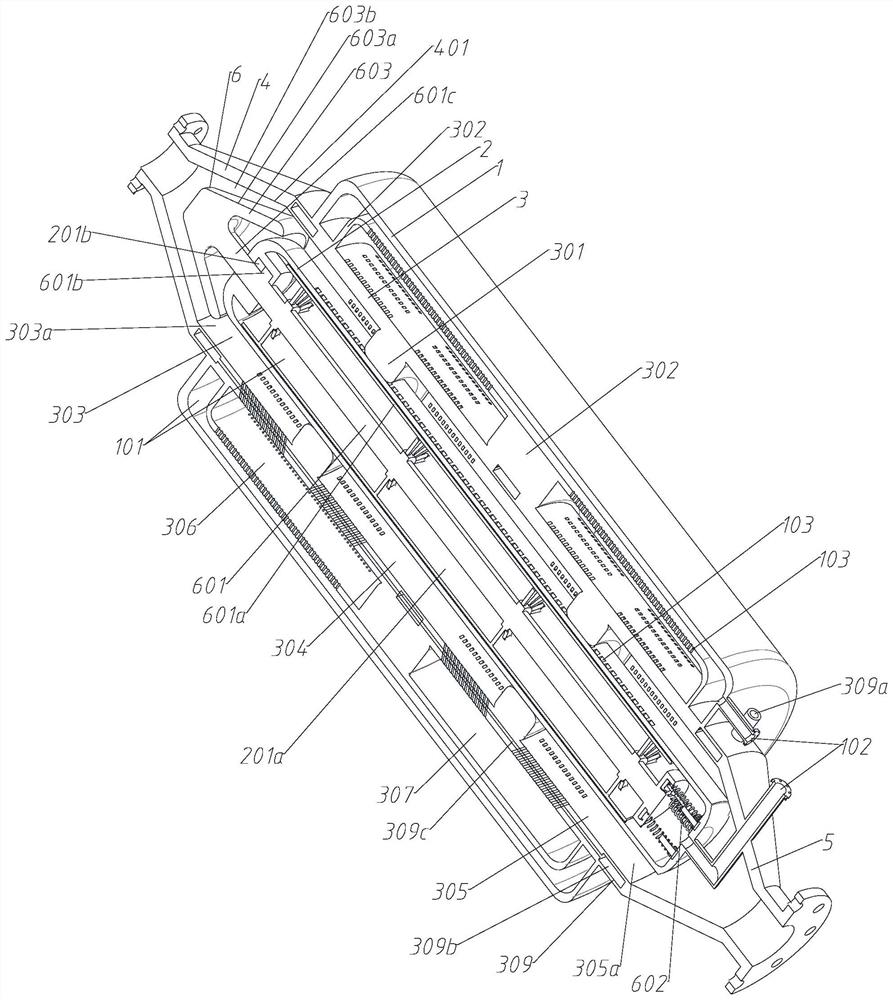

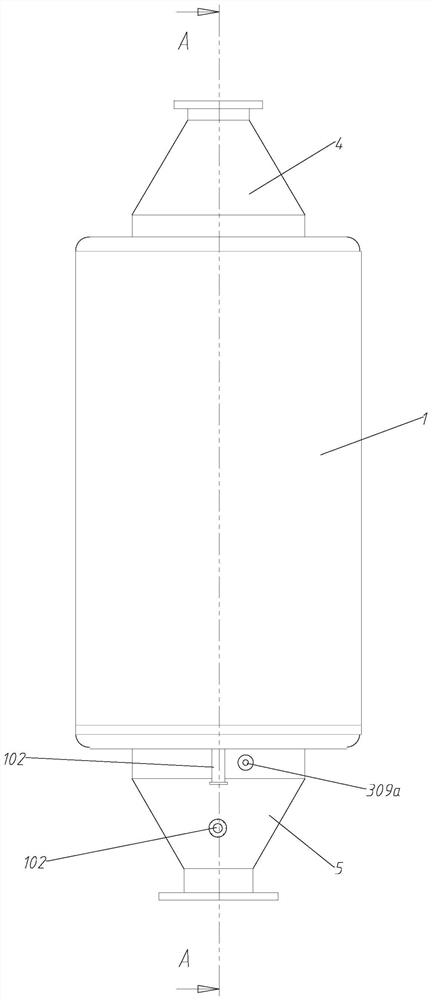

[0045] like Figure 1 to Figure 5 As shown, the present embodiment proposes an oxygen supply device in a deodorant fermentation process, comprising:

[0046] outer tube body 1,

[0047] The inner tube body 2 is arranged in the outer tube body 1,

[0048]The middle tube body 3 is arranged between the outer tube body 1 and the inner tube body 2; wherein, the inner wall of the middle tube body 3 has at least two inner annular edges 301, and the outer wall has at least three outer annular edges 302. The outer annular rim 302 is staggered in sequence; the annular cavity between the middle pipe body 3 and the inner pipe body 2 is divided by the inner annular rim 301 into a first inner annular cavity 303, a second inner annular cavity 304, and a third inner annular cavity arranged in sequence. Cavity 305, the annular cavity between the middle tube body 3 and the outer tube body 1 is divided by the outer annular convex edge into a first outer annular cavity 306 and a second outer an...

Embodiment 2

[0077] In this embodiment, an oxygen supply system in the deodorant fermentation process is proposed, which includes an oxygen supply device in the deodorant fermentation process, and also includes

[0078] The aeration fermentation tank 7 has a number of aeration heads 701 at the bottom of the tank, and the material in it is transported to the feed head 4 of the oxygen supply device in the deodorant fermentation process,

[0079] The oxygen source 8 is connected to the partial aeration head 701 and is connected to the oxygen inlet 102,

[0080] The nitrogen source 9 is connected to the rest of the aeration heads 701 .

[0081] In this embodiment, the large-scale basic oxygen supply and dissolved oxygen of the aeration fermentation tank 7 are organically combined with the details in the deodorant fermentation process in-depth oxygen supply, and the deodorant in the production process can be used in the aeration process. The reciprocating cycle between the fermentation tank 7 ...

Embodiment 3

[0083] In this embodiment, a method for supplying oxygen during the fermentation process of the deodorant is proposed. After the fermentation in the aeration fermentation tank 7 is completed, it is sent to an oxygen supply device for oxygen supply treatment.

[0084] In this embodiment, after the fermentation is completed, the deodorant material is subjected to oxygen supply treatment by the oxygen supply device and then packaged, which greatly improves the final quality of the product, and dissolves enough oxygen more finely, so that the validity period of the product and the deodorization of the product are improved. The effect has been improved qualitatively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com