Auxiliary equipment for anchor rod drawing experiment and experiment instrument

A kind of auxiliary equipment and experimental technology, which is applied in the direction of instruments, scientific instruments, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of connection troubles and difficulties for researchers, and achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

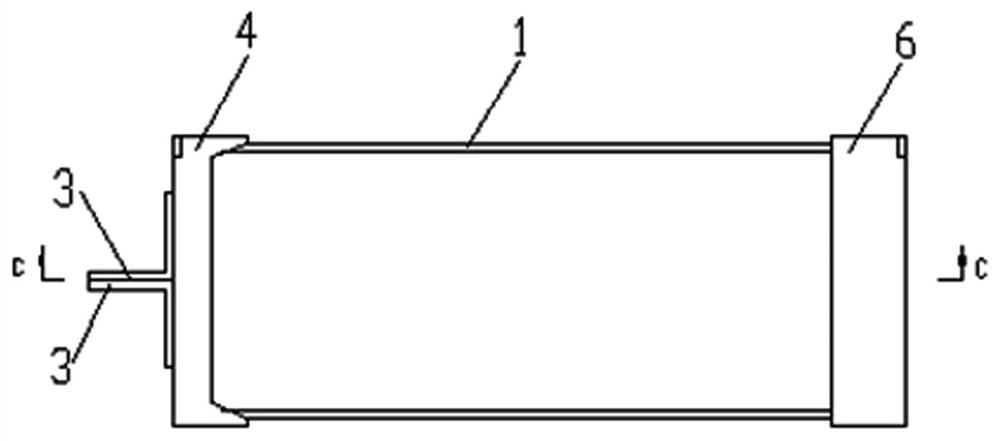

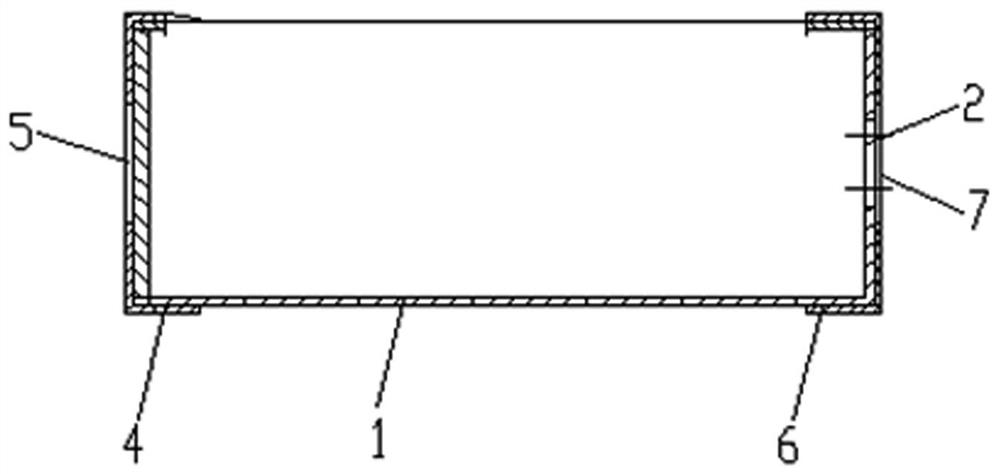

[0036] like Figure 1 to Figure 5 As shown, this embodiment provides an auxiliary equipment for an anchor rod pulling experiment, including a carrying box 1, one side of the carrying box 1 is open, one end of which is fixedly installed with a tensile member, and the other end is provided with a through-hole penetrating through the inside and outside. hole 2.

[0037] During the experiment, manually put the anchor rod 11 to be pulled into the carrying box 1, so that the steel bar at one end of the anchor rod 11 passes through the through hole 2, which is convenient to quickly fix the anchor rod 11, so that the pull test instrument can perform the pull test.

[0038] Preferably, in this embodiment, the carrier box 1 is preferably a rectangular box body with a regular shape.

[0039] This embodiment is simple in structure and reasonable in design, and can realize the fast clamping of the anchor rod 11, so as to quickly complete the pull-out experiment of the anchor rod 11, so as...

Embodiment 2

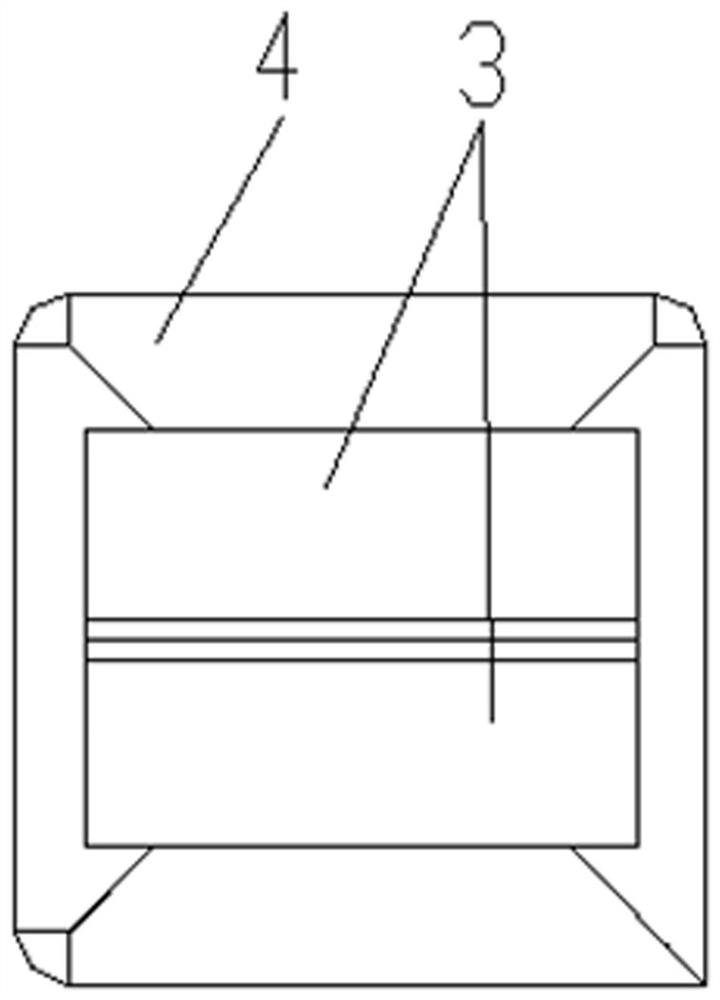

[0041] On the basis of Embodiment 1, in this embodiment, the tension member includes at least one tension plate 3 , and the tension plate 3 is fixedly installed at one end of the carrying box 1 .

[0042] The solution is simple in structure and reasonable in design. During the experiment, the fixing pliers of the pull-out tester can clamp the bearing plate 3 to complete the fast fixing of the anchor rod 11 so as to complete the pull-out test of the anchor rod 11 .

[0043] In addition to the above-mentioned embodiments, the above-mentioned tensile member may also be a tensile rod or a tensile block.

Embodiment 3

[0045] On the basis of Embodiment 2, in this embodiment, the tension member includes two tension plates 3, one end of the two tension plates 3 is fixedly connected to one end of the carrying box 1 respectively, and the other ends are close to each other.

[0046] The structure is simple, the design is reasonable, the bearing capacity of the tension member is enhanced, the service life thereof is prolonged, and the cost is reduced.

[0047] In addition to the above-mentioned embodiments, the tensile plate 3 can also be a flat plate, which is arranged perpendicular to one end of the carrying box 1 , and one end of which is fixedly connected to one end of the carrying box 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com