Inverter compressor starting control method

A frequency conversion compressor, compressor technology, applied in torque pulsation control, starting device, climate sustainability, etc., can solve the problem of the permanent magnet synchronous motor operating environment and working conditions are bad, the starting performance of the frequency conversion compressor affects refrigerators Energy consumption matching test, noise matching test, etc., to achieve the effect of improving startup performance, wide startup performance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

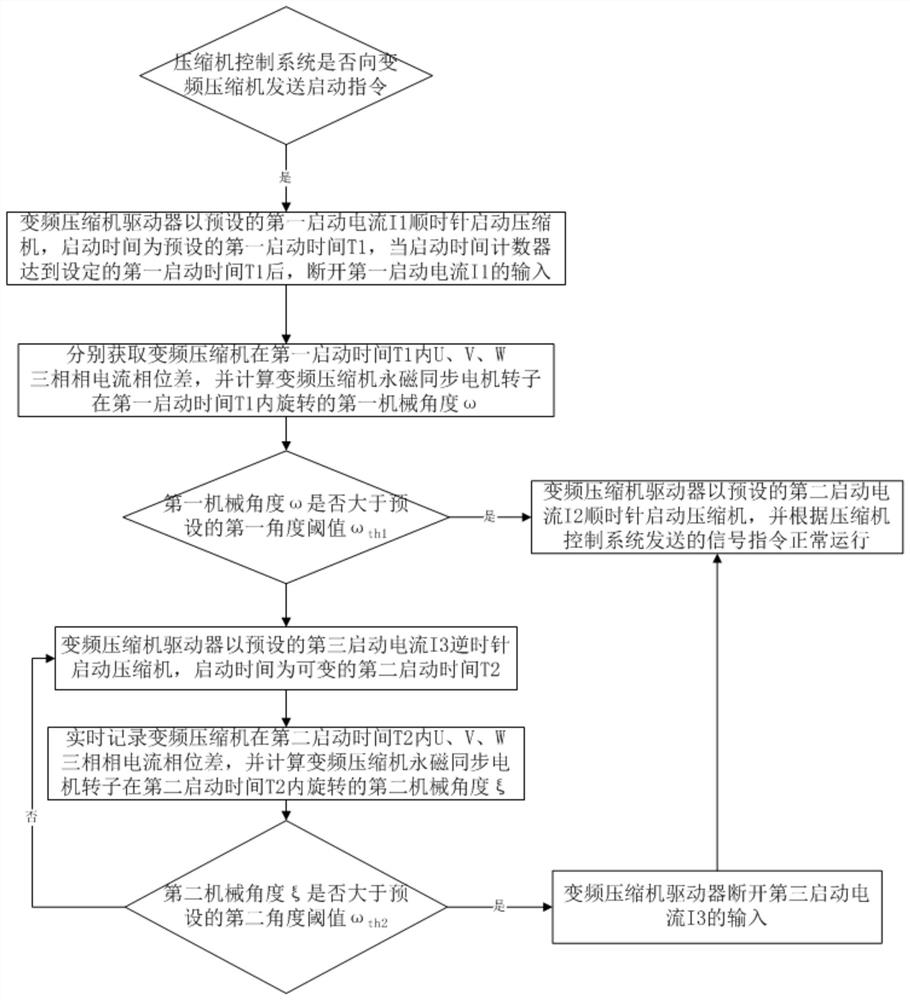

[0021] like figure 1 As shown in the figure, the start-up control method of the inverter compressor includes:

[0022] Step 1. Determine whether the compressor control system sends a start command to the inverter compressor, if so, go to step 2, if not, continue to step 1;

[0023] Step 2. Under the rated load condition, the inverter compressor driver starts the compressor clockwise with the preset first starting current I1, and the starting time is the preset first starting time T1. When the starting time counter reaches the set first starting time After the startup time T1, the input of the first startup curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com