Full-automatic production equipment for square antenna

A production equipment, fully automatic technology, applied in the directions of printed circuits, electrical components, conveyor objects, etc., can solve the problems of poor quality of square antennas, low production efficiency, bad pins, etc., to improve quality and quality, improve production efficiency , the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

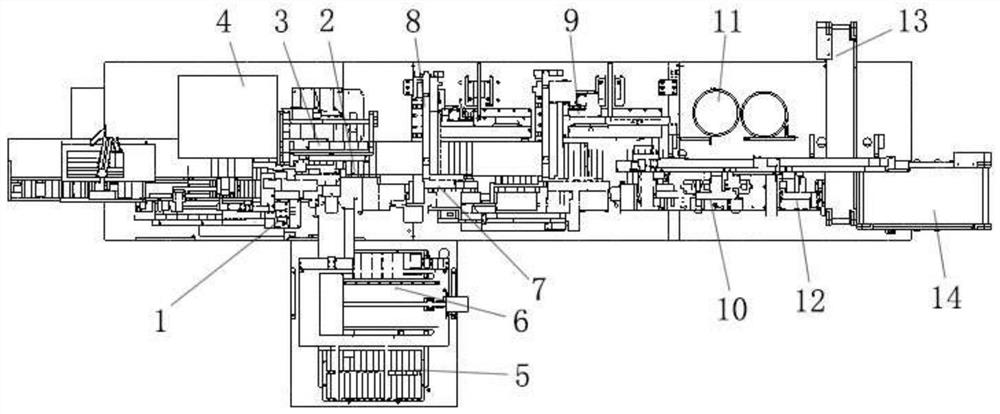

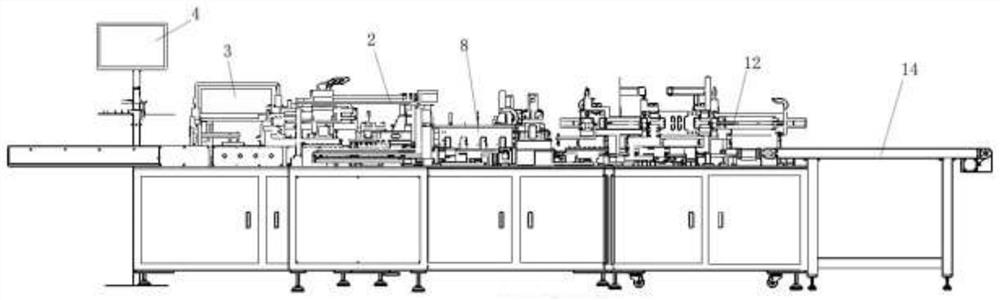

[0036] see Figure 1-10 , which provides a technical solution for the present invention, a square antenna fully automatic production equipment, including a PCB board feeding device and a base shell feeding device; the PCB board feeding device is used for conveying the PCB circuit board 102; the base shell feeding device is used for The transmission antenna housing 151 is connected with a board penetration mechanism at the joint of the discharge end on the back of the base case feeding device and the discharge end on the right side of the PCB board feeding device, and the board penetration mechanism is used to penetrate the PCB circuit board 102 into the feeding device. inside the antenna casing 151 to form the primary product of the antenna;

[0037] The discharge end on the right side of the plate-passing body mechanism is connected with a station conveying mechanism 7, and the discharge end on the right side of the station conveying mechanism 7 is connected with an inner plu...

Embodiment 2

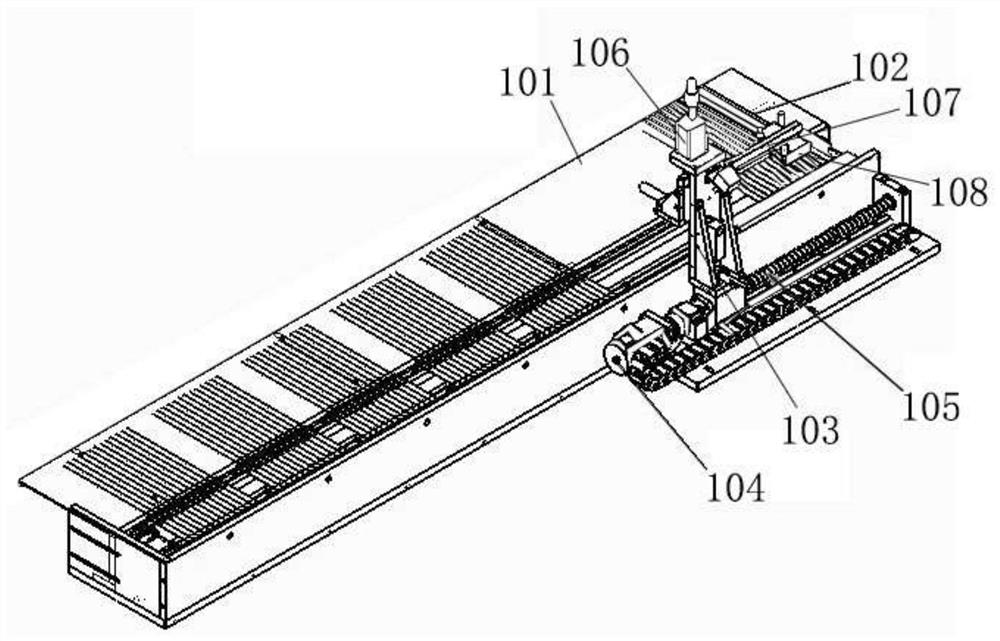

[0043] see figure 1 and image 3 As shown, the PCB board feeding device is composed of a PCB board unloading mechanism 1 and a sub-board conveying mechanism 3. The PCB board unloading mechanism 1 includes a discharge transfer table 101 and a horizontal push mechanism installed on the side of the discharge transfer table 101. , the sub-board conveying mechanism 3 is used to separate the circuit board group into PCB circuit boards 102, and the board-penetrating mechanism is installed on the right side of the sub-board conveying mechanism 3; the horizontal pushing mechanism is used to push the circuit board group to the sub-board conveying mechanism. 3. The horizontal pushing mechanism is composed of a No. 1 motor 104 and a No. 1 screw rod 105. The No. 1 motor 104 and No. 1 screw rod 105 form a screw motor for transporting the PCB circuit board 102. The rod 105 is provided with a movable table 103 , and one side of the movable table 103 is connected with a cross bar 107 , and th...

Embodiment 3

[0051] see Figure 10 As shown, the pin automatic driving device is composed of a vibrating disc 11 and a pin driving mechanism 12. The vibrating disc 11 is used to transport the pins to the pin driving mechanism 12; The moving guide rail 122, the pinning screw motor 123 installed on the moving guide rail 122, and the pin suction part installed on the support table 121, the pin suction part is composed of the No. 5 cylinder 124 and the No. 5 suction cup 125; the No. 5 cylinder No. 124 and No. 5 suction cups 125 drive pins into the rotating shaft position of the intermediate product of the antenna to form a square antenna, wherein the pin-driving mechanism 12 also includes a No. 5 vacuum generator 126 and is installed on the support 121 for displaying No. 5 The vacuum generator 126 operates the negative pressure gauge 127 of the air pressure; the operation of the No. 5 vacuum generator 126 drives the No. 5 suction cup 125 to generate suction to suck the pins for pinning work. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com