Roller, calender and method for configuring control and/or regulation unit

A technology for adjusting units and calenders, which is applied to calenders, paper machines, textiles and papermaking, etc., can solve the problems of separate reporting and non-obtainability, and achieve the effect of time-saving and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

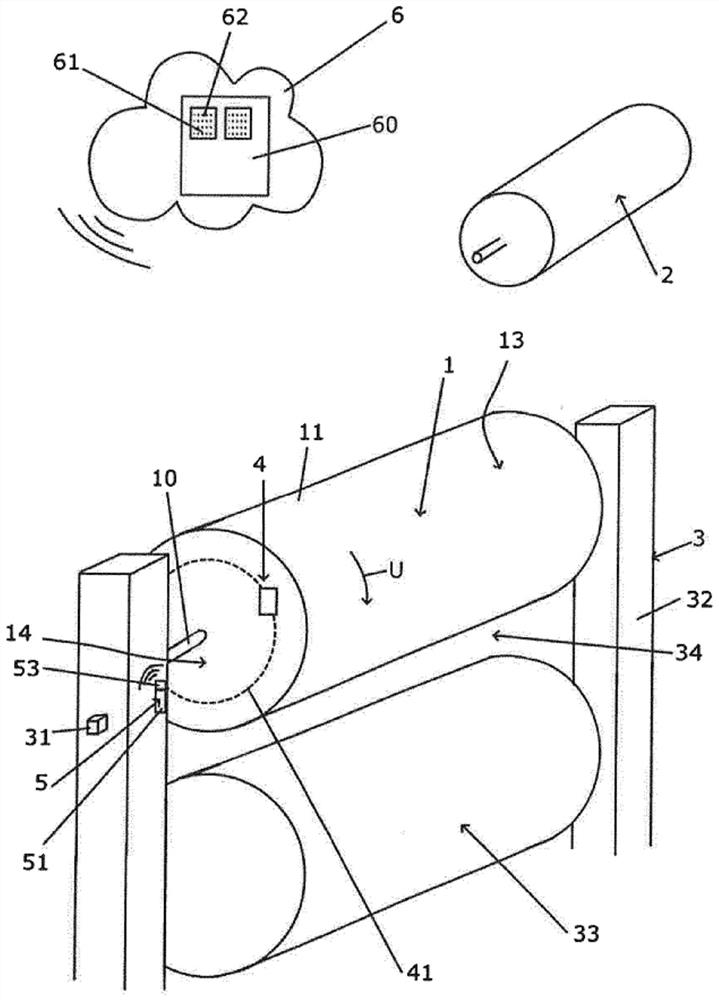

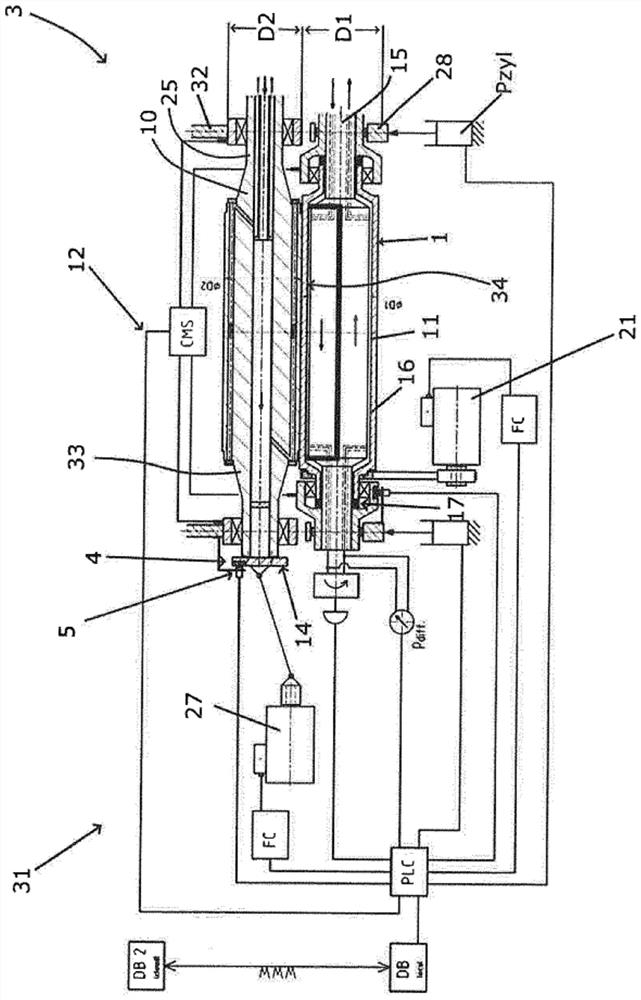

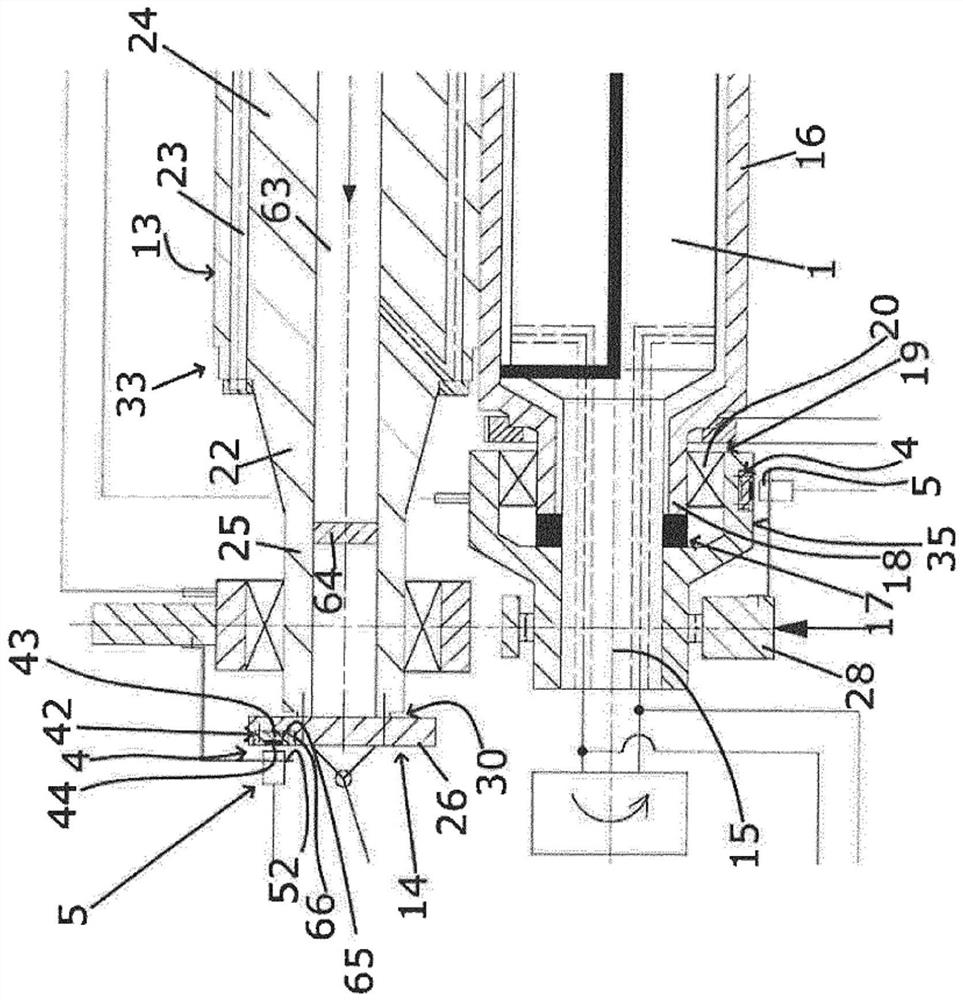

[0054] exist figure 1 Zhongchun schematically shows a perspective view of the inventive calender 3 with the inventive roll 1 arranged thereon.

[0055] For the purposes of the present invention, the calender 3 may have any structural form. For example, the calender 3 can carry more than one roll 1 in order to achieve a quick roll change in a manner known per se. exist figure 1 In the design shown, the calender 3 is shown generally only as a base frame 32 carrying said roll 1 and a counter roll 33 for the sake of clarity. For greater clarity, the roller drives are also not shown.

[0056] The roll 1 is used for processing nonwoven webs, textile webs, plastics webs or paper webs and has a roll stand 10 and a roll body 11 forming a working side perimeter 13 . The roller 1 can be constructed in any form, in figure 1 are also only shown schematically for the sake of clarity.

[0057] exist figure 1 In the case shown, a roll 2 previously arranged on the calender 3 has been re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com