Synchronous flattening structure for flaky materials

A material, sheet-like technology, applied in thin material processing, sending objects, transportation and packaging, etc., to ensure the effect of flattening and pressing, reducing costs, and ensuring the effect of flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

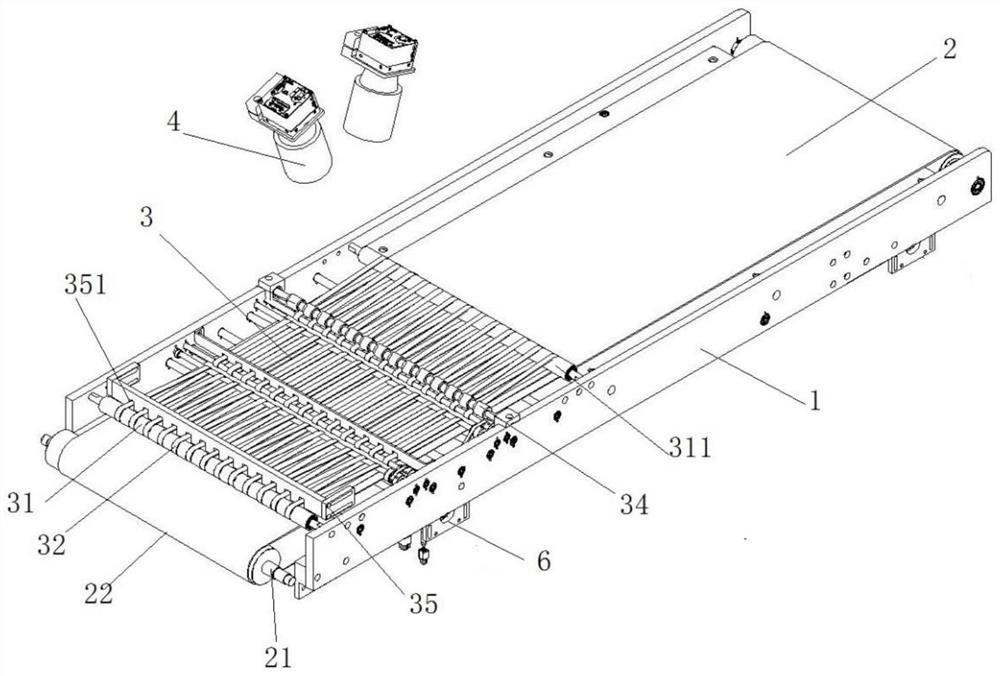

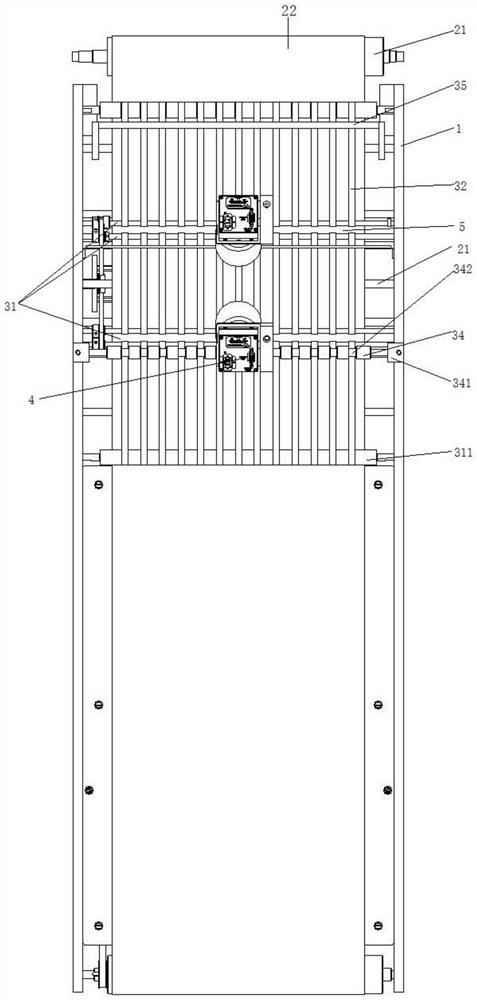

[0024] like Figure 1~3 As shown, a sheet material synchronous flattening structure includes a frame 1, a conveying assembly 2, a flattening assembly 3, a driving assembly and a detection element 4, and the driving assembly, Conveying component 2 , flattening component 3 and detection element 4 .

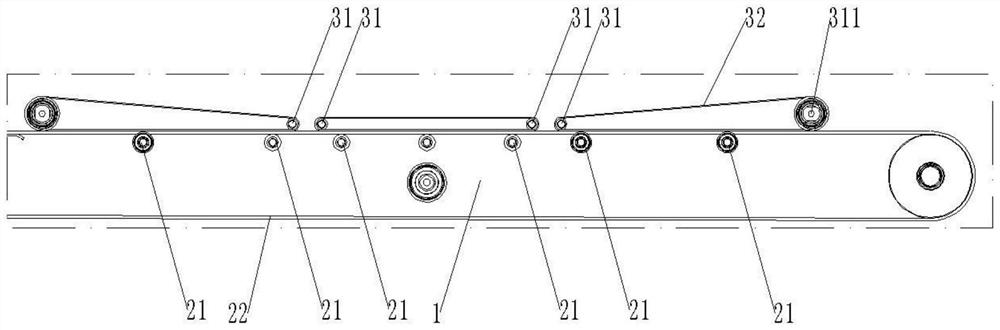

[0025] Specifically, the conveying assembly 2 includes a lower conveying roller 21 and a lower conveying belt 22, the lower conveying roller 21 is rotatably connected to the frame 1, and the lower conveying belt 22 cooperates and covers the lower conveying roller 21, which is a hard conveyor belt.

[0026] Specifically, the flattening assembly 3 includes an upper conveying roller 31 and an upper conveying belt 32. The upper conveying belt 32 is located above the lower conveying belt 22 and is an elastic belt. A plurality of upper conveyor belts 32 are arranged side by side; the upper conveyor rollers 31 and the upper conveyor belts 32 are respectively matched and sequentially form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com