Concrete frame appearance quality defect repairing method

A technology of appearance quality and defect repair, applied in building maintenance, construction, building construction, etc., to achieve the effect of beautiful appearance, improved construction quality, and durable quality

Pending Publication Date: 2022-06-10

CHINA NAT CHEM ENG NO 14 CONSTR

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002]The current concrete frame plus steel structure truss, due to the quality of commercial concrete raw materials, formwork leveling and cleanliness, and the technical level of construction personnel during the construction process, after the concrete components are demolished There is a high probability of common defects in appearance quality, usually including honeycomb, pockmarks, holes, etc., which may even cause leaks in serious cases, which will affect the service life of concrete structures. Conventional methods for repairing appearance defects in concrete can only be repaired in a small area, and After the construction is completed, there is a color difference between the repaired part and the original concrete part, which affects the perception effect. In addition, conventional concrete repair materials are greatly affected by the external environment, and quality problems are prone to occur during subsequent maintenance and use. The overall quality cannot be guaranteed for a long time. Therefore, it is necessary to develop a new type of fair-faced concrete appearance repair technology, aiming at repairing the appearance quality defects of concrete frames, and providing technical guidance for subsequent construction of similar projects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

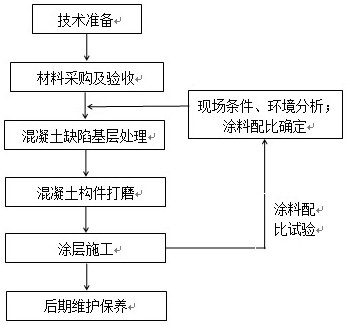

The invention discloses a method for repairing appearance quality defects of a concrete frame, which is characterized in that different treatment schemes are made according to various defects of the concrete appearance, color difference of a construction forming part is avoided by combining the optimal proportion of a field construction environment test coating, and technical innovation is carried out in the aspects of base layer treatment, coating proportion, later maintenance and the like. Compared with a conventional repairing technology, the novel method is wider in repairing area, more attractive in appearance forming, shorter in coating solidification time, more durable in quality and longer in maintenance time, the probability of problems in the maintenance process is reduced, outdoor engineering construction can be better met, economic benefits are improved, and the novel method is worthy of popularization.

Description

technical field [0001] The invention belongs to the field of repairing appearance quality defects of reinforced concrete, and in particular relates to a method for repairing appearance quality defects of concrete frames. Background technique [0002] The current concrete frame plus steel structure truss, due to the quality of commercial concrete raw materials, formwork leveling and cleanliness, and the technical level of construction personnel during the construction process, there is a high probability of common defects in the appearance of concrete components after formwork removal, usually including honeycomb, pitting, Holes, etc., serious and even lead to missing reinforcement, will affect the service life of the concrete structure, the conventional repair method of concrete appearance defects can only be repaired in a small area, and after the construction is completed, there is a color difference between the repaired part and the original concrete part, which affects th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G23/02

CPCE04G23/0296E04G23/0211

Inventor 祝勤胡杰光王强张永

Owner CHINA NAT CHEM ENG NO 14 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com