Production method of fen-flavor liquor

The technology of a kind of fragrance type liquor and its production method, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of single taste, failure to meet market demand, bitter aftertaste, etc., and achieve improved liquor yield, harmonious and comfortable compound aroma, and sweetening Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

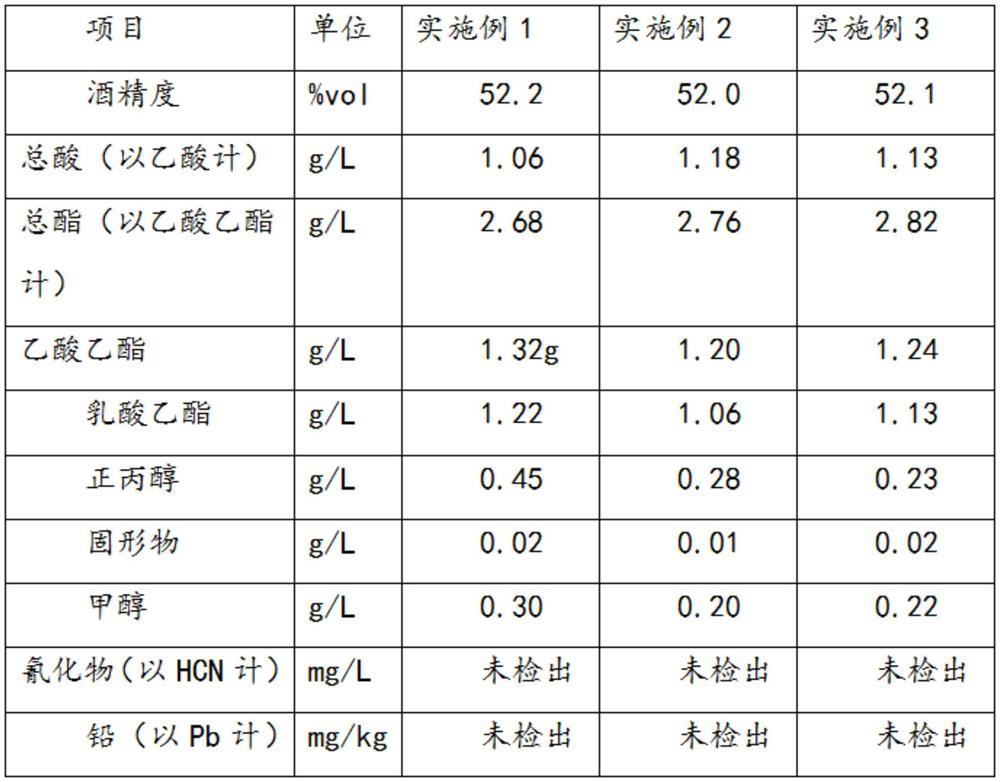

Examples

Embodiment 1

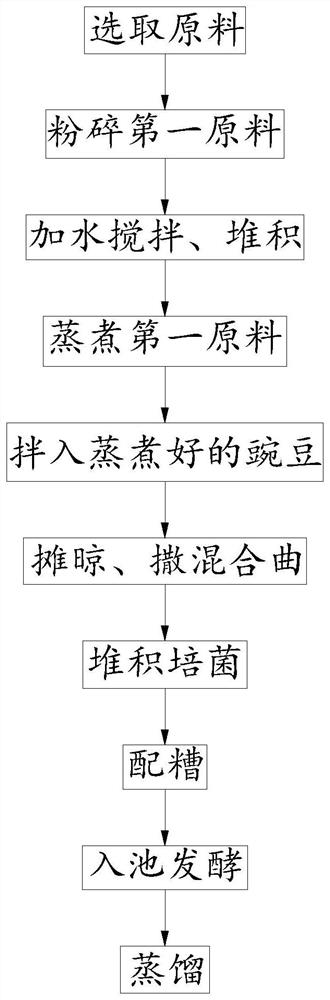

[0039] like figure 1 As shown, in embodiment 1, the present embodiment provides a kind of production method of fragrance type liquor, comprises the steps:

[0040] Step 1: choose raw material, get sorghum 56kg, rice 33kg, glutinous rice 23kg, wheat 22kg, corn 10kg, pea 6kg;

[0041]Step 2: pulverize the first raw material, the first raw material includes sorghum, corn, glutinous rice, rice, and wheat. The pulverized first raw material can pass through the 20-mesh sieve. The fine powder accounts for 30-35%, and the coarse powder accounts for 55- 60%;

[0042] Step 3: add water, stir, stack, add water to the pulverized first raw material and stir evenly, stack the first raw material after stirring evenly, add hot water with a raw material amount of 55% and a water temperature of 80 ° C to moisten the grains , the amount of water is about 60kg, the time for moistening the grain is 12h, and the pile is turned 2-3 times in the middle. When the temperature rises to 40 °C, the stea...

Embodiment 2

[0052] like figure 1 As shown, in embodiment 2, the present embodiment provides a kind of production method of fragrance type liquor, comprises the steps:

[0053] Step 1: choose raw material, get sorghum 62kg, rice 32kg, glutinous rice 24kg, wheat 20kg, corn 9kg, pea 5kg;

[0054] Step 2: pulverize the first raw material, the first raw material includes sorghum, corn, glutinous rice, rice, and wheat. The pulverized first raw material can pass through the 20-mesh sieve. The fine powder accounts for 30-35%, and the coarse powder accounts for 55- 60%;

[0055] Step 3: adding water, stirring and stacking, adding water to the pulverized first raw material and stirring evenly, and stacking the uniformly stirred first raw material, adding 42% of the raw material with hot water with a water temperature of 80°C to moisten the grain, The amount of water is about 63kg, the time for moistening the grain is 10h, and the pile is turned 2-3 times in the middle. When the temperature rises ...

Embodiment 3

[0065] like figure 1 As shown, in embodiment 3, the present embodiment provides a kind of production method of fragrance type liquor, comprises the steps:

[0066] Step 1: choose raw material, get sorghum 60kg, rice 30kg, glutinous rice 22kg, wheat 18kg, corn 12kg, pea 8kg;

[0067] Step 2: pulverize the first raw material, the first raw material includes sorghum, corn, glutinous rice, rice, and wheat. The pulverized first raw material can pass through the 20-mesh sieve. The fine powder accounts for 30-35%, and the coarse powder accounts for 55- 60%;

[0068] Step 3: adding water, stirring and stacking, adding water to the pulverized first raw material and stirring uniformly, and stacking the uniformly stirred first raw material, adding 38% of the raw material with hot water with a water temperature of 80° C. to moisten the grain, The amount of water is about 57kg, the time for moistening the grain is 12h, and the pile is turned 2-3 times in the middle. When the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com