Product crusher

A pulverizer and product technology, applied in grain processing, etc., can solve the problem that product bridging cannot be completely eliminated, and achieve the effects of eliminating product bridging, reducing labor, and improving the accuracy of sample analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1 How it works

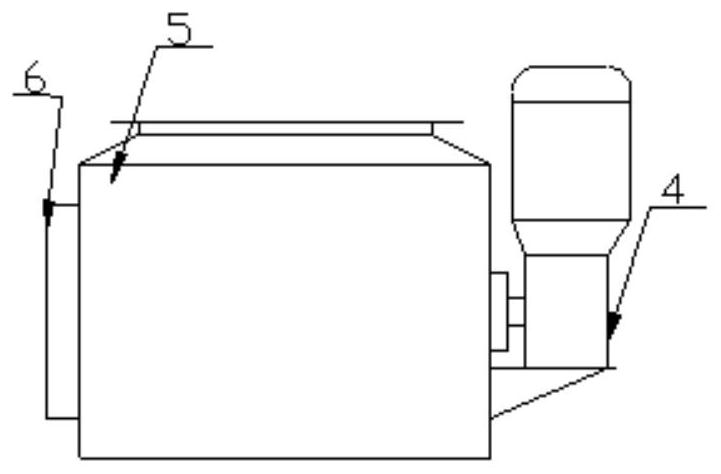

[0020] The pulverizer is powered by a motor and is a high-speed moving equipment. In the process of crushing the product, the "111" product crusher will crush the "111" product quickly, and the product will be thrown out of the product barrel under the action of centrifugal force. like figure 1 Therefore, it is necessary to control the speed of the pulverizer, and a reducer is used to reduce the speed of the motor to 75-100n / s to reduce the centrifugal force during the pulverization of the "111" product particles, so that the "111" product particles fall freely into the in the product barrel.

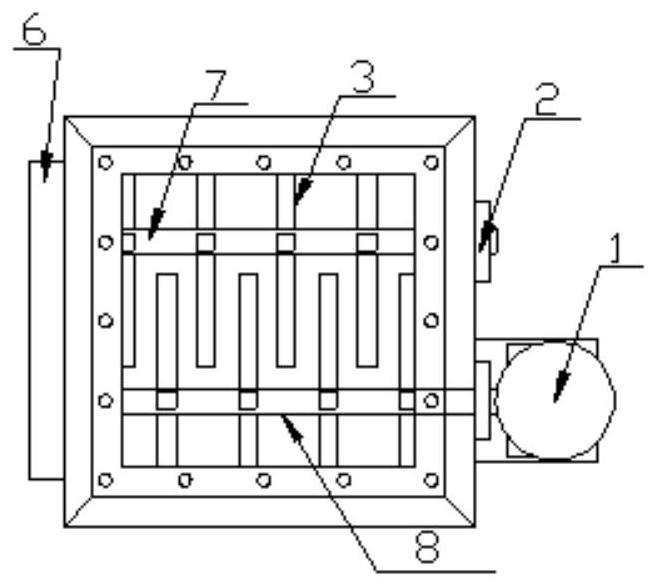

[0021] like figure 1 As shown in the figure, the cutter is welded on the 8 main shafts and the auxiliary shaft. The working principle is that the motor drives the 8 main shafts of the pulverizer to rotate, and the 7 auxiliary shafts are driven by the 6 transmission mechanism, so that the main shaft and the auxiliary shaft drive the cutter to rotate inward. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com