A center frame device for machining aircraft landing gear and its clamping method

An aircraft landing gear and center frame technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as damage to the stability of the center frame structure, reduced workpiece machining accuracy, and surface cracks on the center frame. Improve work efficiency, ensure durability, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention are described below to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Such changes are obvious within the spirit and scope of the present invention as defined and determined by the appended claims, and all inventions and creations utilizing the inventive concept are within the scope of protection.

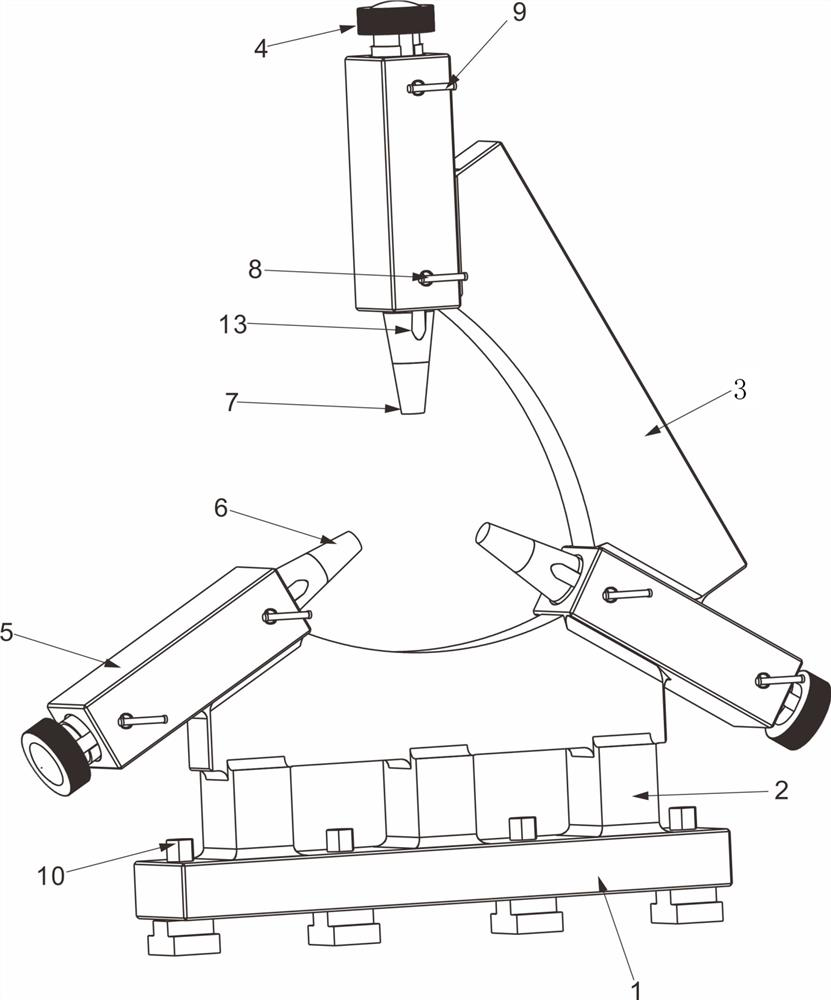

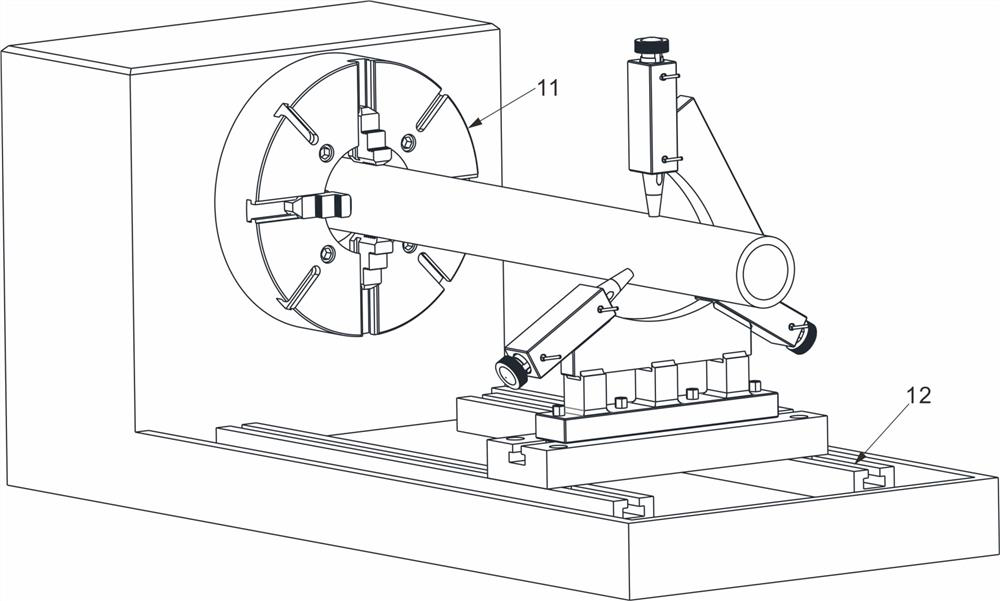

[0029] like figure 1 and figure 2 As shown, the center frame device for aircraft landing gear processing in this scheme includes a base 1, the upper end of the base 1 is provided with a center frame 3, the center frame 3 is an open ring structure, and both ends and the middle of the center frame 3 are provided with support arms 5. The three support arms 5 are evenly distributed at an angle of 120° on the annular structure, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap