Fuel tank capable of being flexibly fixed and loading machine

A fuel tank and flexible technology, applied in the field of construction machinery, can solve problems such as potential safety hazards, deformation of the guard plate, and affecting the efficiency of disassembly and assembly, and achieve the effect of reliable structure, easy implementation, and both disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

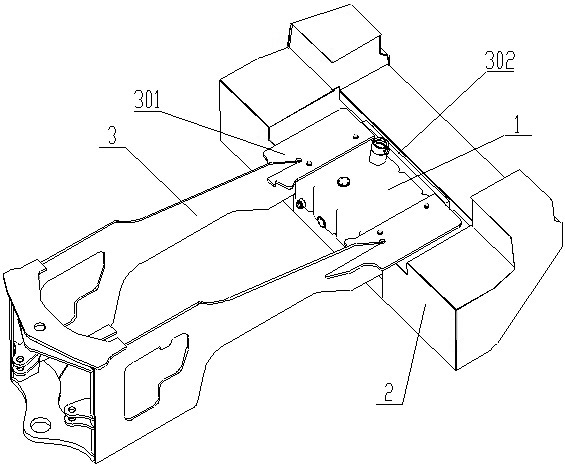

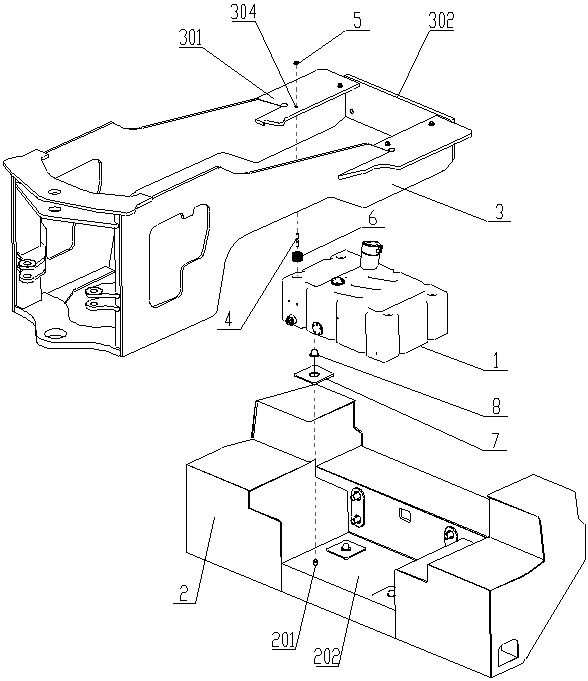

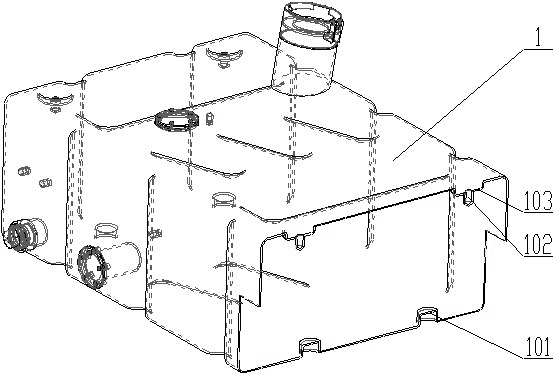

[0019] like Figure 1 to Figure 5 A fuel tank and a loader that can be flexibly fixed as shown include a vehicle frame 3, and the vehicle frame 3 is connected with a counterweight 2, and a fuel tank 1 is arranged between the vehicle frame 3 and the counterweight 2. The counterweight is provided with a counterweight platform 202 for supporting the fuel tank 1. The counterweight platform 202 is provided with a raised limit block 201, and the lower part of the fuel tank 1 is provided with a raised limit block 201. The installation groove 101 used is provided with a damping rubber cap 7 and a rubber pad 8 between the installation groove 101 and the raised limit block 201; the upper part of the fuel tank 1 is provided with an installation hole 102 and a counterbore I 103 , the mounting hole 102 is provided with a double-ended stud 4, the double-ended stud 4 is covered with a limit spring 6, and the bottom of the frame 3 shows that there is a Light hole 304 and counterbore II 303 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com