Novel uranium dioxide hydrofluorination two-stage full-countercurrent series fluidized bed system

A uranium dioxide, fluidized bed technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of low production capacity of process production routes, complicated personnel maintenance operations, and failure to achieve full countercurrent contact, etc., to reduce HF The effect of excess capacity, convenient operation and maintenance, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

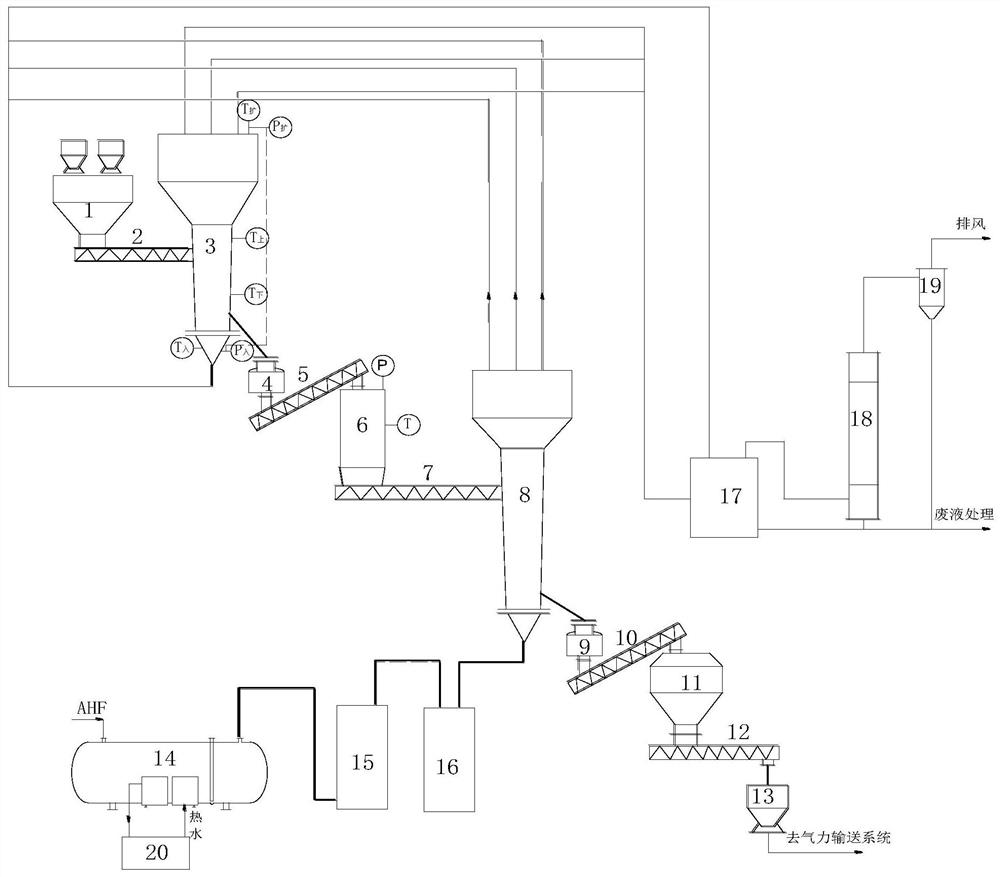

[0017] The hydrofluorination system consists of: the feeding hopper 1 is connected with the screw conveyor A2, the screw conveyor A2 is connected with the primary fluidized bed 3, the primary fluidized bed 3 is connected with the telescopic hopper A4, and the telescopic hopper A4 is connected with the screw conveyor B5 is connected, the screw conveyor B5 is connected with the intermediate hopper 6, the intermediate hopper 6 is connected with the screw conveyor C7, the screw conveyor C7 is connected with the secondary fluidized bed 8, the secondary fluidized bed 8 is connected with the telescopic hopper B9, the telescopic hopper B9 is connected with the screw conveyor D10, the screw conveyor D10 is connected with the storage tank 11, the storage tank 11 is connected with the screw conveyor E12, the screw conveyor E12 is connected with the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com