Retaining ring adjusting device of vertical roller mill

A technology of adjusting device and retaining ring, applied in the direction of grain processing, etc., can solve the problems of destroying the stability of the material layer, reducing the current of the mill, and reducing the grinding efficiency of the mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

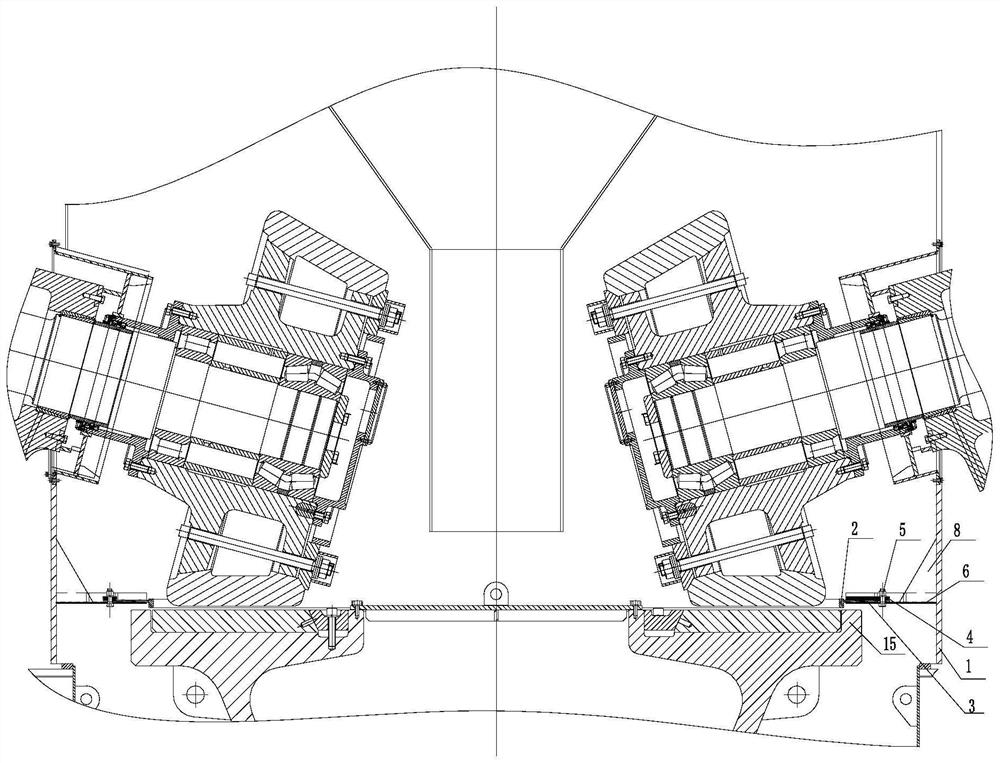

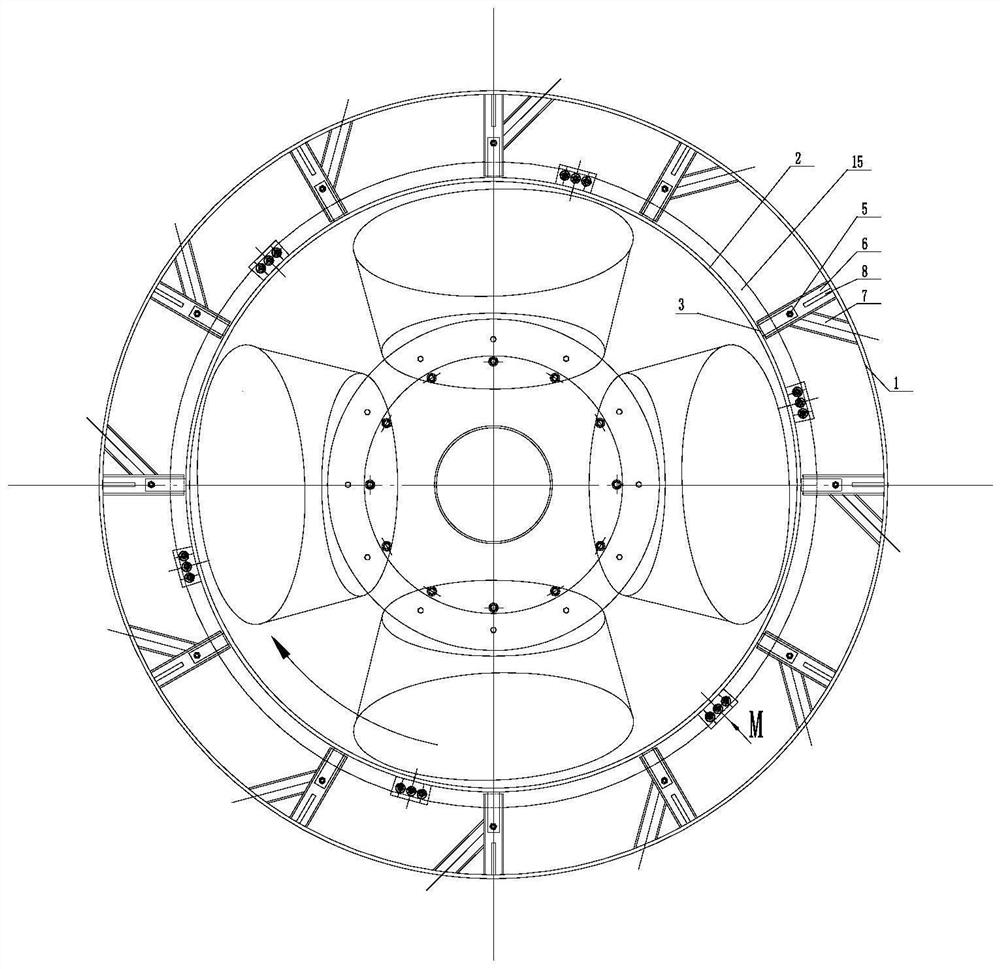

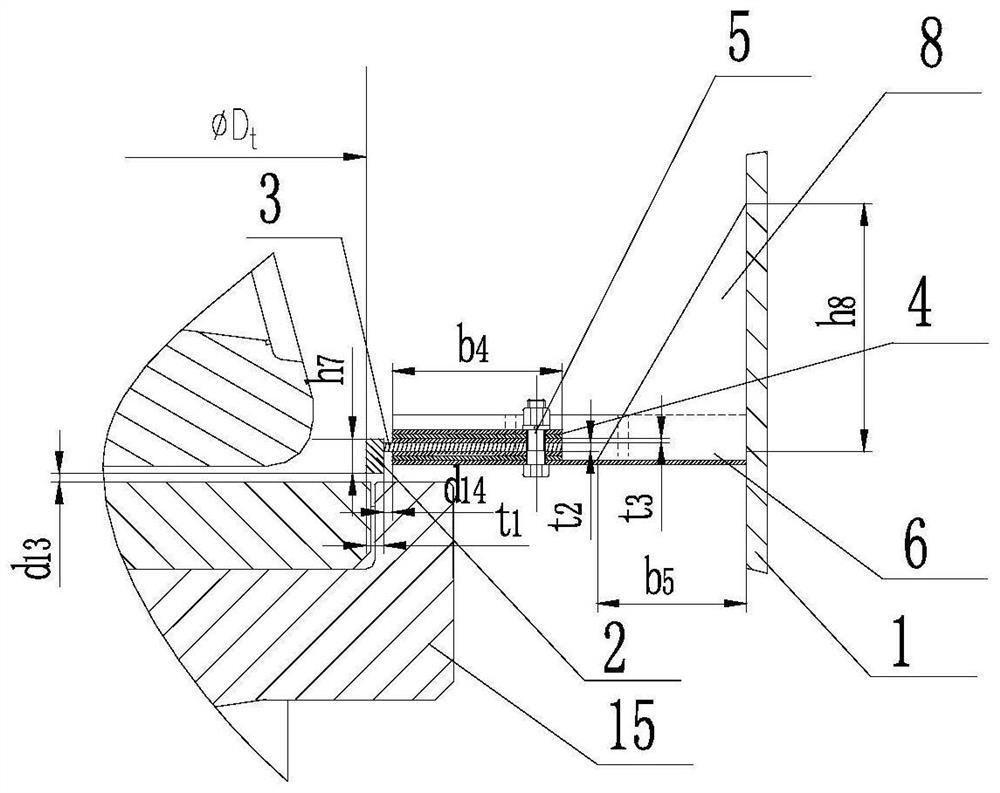

[0034] Example 1, see Figure 1 to Figure 6 , a vertical roller mill retaining ring adjustment device, including a mill shell, a grinding disc 15, several grinding rollers, a blanking cone and a retaining ring 2; the outer side of the retaining ring is installed with the retaining ring and the A retaining ring adjustment mechanism is formed between the grinding discs to form a fine powder discharge gap. In this embodiment, the baffle ring adjustment mechanism adopts a built-in baffle ring adjustment mechanism, and the built-in baffle ring adjustment mechanism is installed in the shell 1 of the mill; The retaining ring support 3, the above retaining ring support can be installed on the upper or lower part of the radial support according to the needs of the gap between the retaining ring and the grinding disc; several height adjustment pads are arranged above the retaining ring support 4. The number and vertical position of the above-mentioned height adjustment plates can be ad...

Embodiment 2

[0039] Example 2, see Figure 7 to Figure 9 , a vertical roller mill retaining ring adjustment device, including a mill shell, a grinding disc, several grinding rollers, a blanking cone and a retaining ring 2; A retaining ring adjustment mechanism forming a fine powder discharge gap between them. In this embodiment, the baffle ring adjustment mechanism adopts an external baffle ring adjustment mechanism; the external adjustment device is installed outside the shell 1 in the mill; it includes a baffle ring welded on the outer wall of the baffle ring in the radial direction The support 3, the retaining ring support is fixedly installed on the radial support 6 through the fastener 5, and the radial support upper rib 9 is welded on the upper surface of the radial support near the shell side of the mill. There is a chute 1-1 on the shell of the mill at the position corresponding to the upper rib of the radial support; the upper rib of the radial support is an L-shaped structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com