Method for mounting shaft, in particular camshaft, in bearing guide rail of internal combustion engine

A technology for bearing guide rails and internal combustion engines, which is applied in the directions of engine seals, valve devices, mechanical equipment, etc., can solve the problems of inability to install space in the engine compartment and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

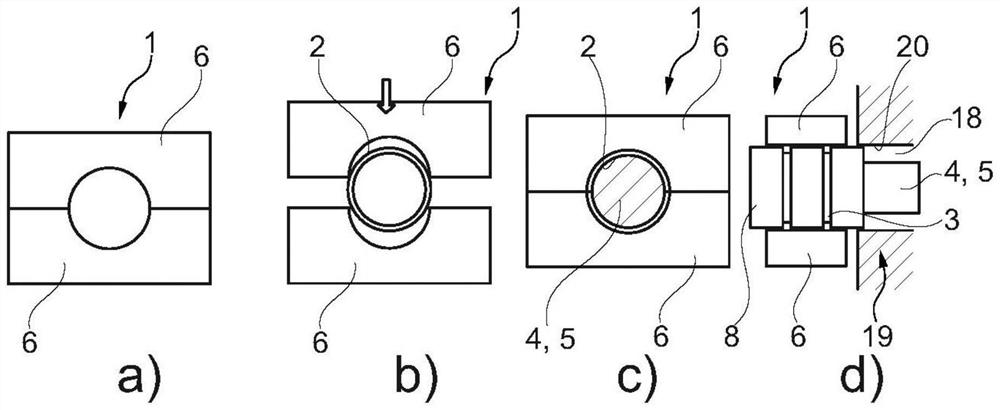

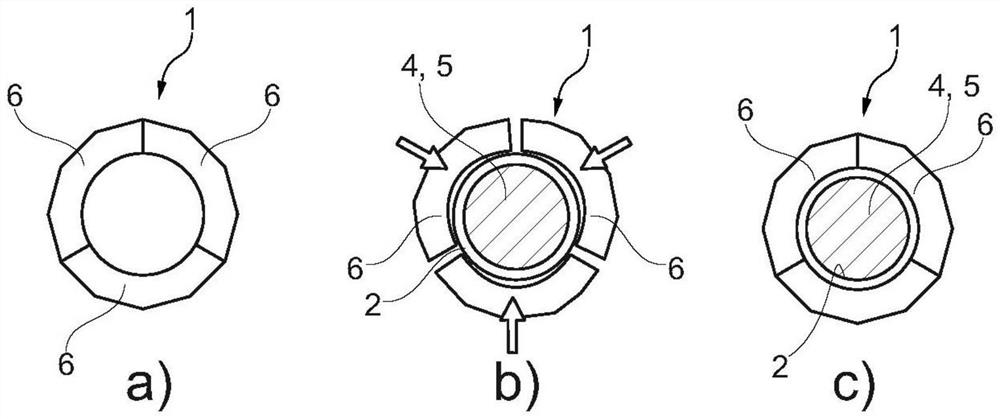

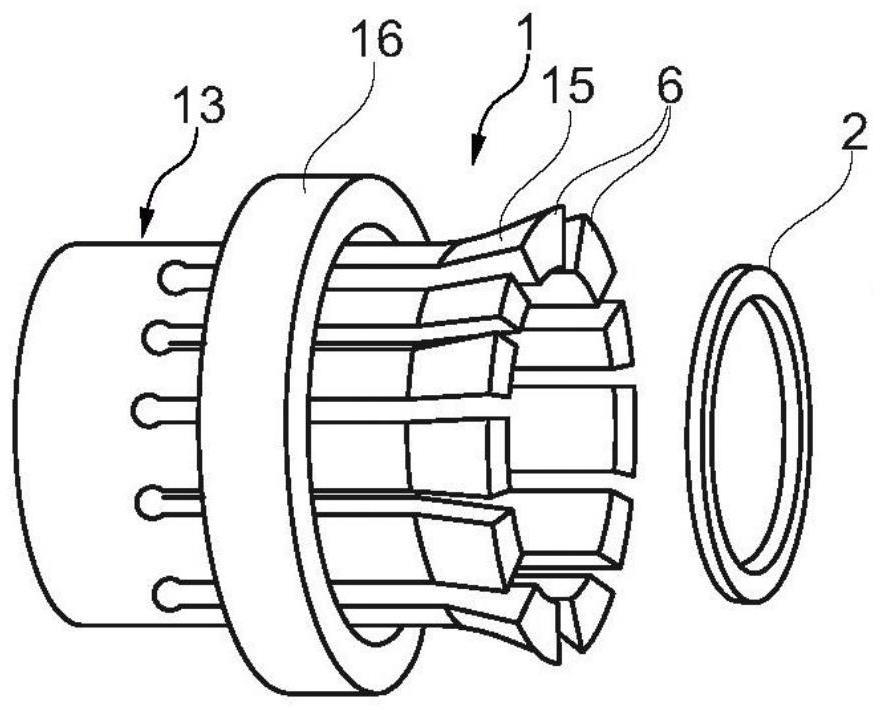

[0037] according to Figure 1 to Figure 7 , shows a calibration tool 1 according to the invention, by means of which the sealing ring 2 can be calibrated or compressed so as to be pressed into the groove 3 of the shaft 4 (eg camshaft 5 ) (see figure 1 b to figure 1 d. figure 2 b and figure 2 c and Figure 4 ). The calibration tool 1 here has at least two radially displaceable, partially circular clamping jaws 6 (according to the figure 1 a to figure 1 d is the two jaws 6, according to figure 2 a to figure 2 c is the three jaws 6, according to image 3 A total of eleven jaws 6). on the basis of Figure 5 to Figure 7 In the case of the calibration tool 1 , the calibration tool has a displaceable belt clip 7 , with which a reduction in the diameter D of the sealing ring 2 can be achieved by shrinking.

[0038] The method according to the invention for mounting the shaft 4 in the bearing guide 18 of the internal combustion engine 19 is constructed as follows: First,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com